New thinking about manufacturing

Driving inclusive growth in UK industry

Women make up nearly half of the UK workforce but hold under a third of manufacturing roles and earn 15% less than men. The Women in Manufacturing UK Initiative (WiM UK) is driving change by working with industry, policymakers, and researchers to embed equity, diversity, and inclusion across the sector. Dr Jennifer Castañeda-Navarrete, Principal Policy Analyst highlights why this matters — and the leadership actions needed to make inclusion a reality.

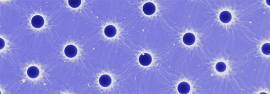

Unlocking the potential of nanomaterials: Paving the way for next-generation device manufacturing

Groundbreaking research at the IfM, in collaboration with partners across the UK and internationally, has received a significant boost with the announcement of the second phase of the Engineering and Physical Sciences Research Council (EPSRC) ‘Adventurous Manufacturing’ grant.

Empowering women in manufacturing: paving the way for inclusive leadership and industry growth

Women in Manufacturing UK is driving change across the industry by promoting gender inclusion and diverse leadership. We explore their efforts to increase women's representation and help shape a more innovative, resilient, and inclusive future for manufacturing.

Laser-assisted cold spray: a new generation of innovative manufacturing technology

The IfM's Centre for Industrial Photonics (CIP) has developed a groundbreaking additive manufacturing technique, laser-assisted cold spray (LACS), demonstrating its effectiveness in aerospace applications, where high-precision and localised material deposition are critical.

Achieving net zero in manufacturing supply chains

In today’s industrial landscape, achieving net-zero targets is a key goal for sustainable manufacturing, but addressing broader Scope 3 emissions across product life cycles and supply chains remains challenging. The IfM’s Centre for International Manufacturing is tackling these complexities head-on. Jagjit Singh Srai, Head of the Centre, shares innovative strategies transforming manufacturing value chains toward greater sustainability.

From plastic waste to better homes in Nepal

Nepal faces a growing plastic waste crisis, with 600 tonnes littering streets and mountains daily. Dr. Curie Park’s Plastic to Ghar (P2G) project, supported by UK Aid and UNCTAD, empowers communities to turn plastic waste into sustainable building materials, transforming pollution into a resource and creating local hubs for innovation.

Gamifying sustainability: delivering worker engagement and environmental impact

Raynor Foods is renowned for its innovative initiatives and is currently focusing on the challenge of inspiring its entire workforce to enhance sustainability. In pursuit of this goal, they have initiated the S3 Project in partnership with academic and technological collaborators to establish a digital twin factory for real-time monitoring of carbon emissions. They plan to use gamification to involve employees in reducing the company’s carbon footprint.

Navigating an uncertain world: future-proofing global supply chains

In the wake of trade conflicts, Brexit, and the COVID-19 pandemic, global supply chains' vulnerabilities have become apparent. "Future-proofing" supply chains is crucial, involving anticipating disruptions, embracing advanced technologies, and considering sustainability and geopolitical dynamics.

Improving supply chain ethics with the industrial metaverse

In today’s globalised business world, there is a growing need for ethical supply chain practices. Manufacturing companies are facing complex challenges in modern production, and the importance of transparency and accountability has never been greater. IfM researchers Nikolai Kazantsev, Bethan Moncur, Bang Yong Min and Professor Chander Velu explain.

Sustainability: making the invisible visible

In our conversation with the IfM's Centre for Industrial Sustainability, we explore the crucial importance of making industrial resources more visible. By bringing to light some of the often neglected aspects, we discover how — as resources become more visible — their value increases, which results in a crucial step towards achieving environmental, climatic, and financial benefits.

Driving change: in pursuit of cobalt-free batteries

Head of the IfM’s Nanomanufacturing Group, Professor Michael de Volder, sheds light on pioneering efforts to eliminate cobalt from electric vehicle batteries, offering a glimpse into a more sustainable era for electric mobility.

AI for asset management and predictive maintenance

In this webinar Ajith Parlikad, Professor of Asset Management, IfM, University of Cambridge, explores how organisations can leverage AI to optimise operations, reduce downtime, and enhance overall efficiency.

The quantum leap

Quantum computing looks set to play a key role in the future of manufacturing. The IfM’s Professor Chander Velu explains how companies can best prepare.

Staying ahead of the curve: Rethinking Innovation at Domino Printing

Industrial printing firm Domino Printing Sciences has been able to stay ahead of its competitors by rethinking its approach to innovation, using approaches and frameworks from the IfM.

AI applications including enhanced process control

In this webinar we give an overview of AI applications in manufacturing, before considering how it is being used to enhance process control and optimisation. IfM experts present how AI can and is being used for quality assurance, improving operational performance.

The 10 factors of digital transformation success

IfM Engage Industrial Associate Kam Gossal explains how manufacturers can best align their digital transformation programmes and the key factors behind success.

Machining the future: The AI advantage

The field of AI is advancing rapidly, with ongoing improvements in AI models and sensors presenting exciting prospects for enhancing manufacturing and design processes. IfM Associate Professor Sebastian Pattinson delves into how AI could improve processes and provides valuable tips for using AI-controlled systems effectively.

Manufacturing a more equitable world through informed policy-making

Jennifer Castañeda Navarrete, a Senior Policy Analyst for Cambridge Industrial Innovation Policy tells us about her work and dedication to addressing the problem of women's underrepresentation in the industrial sector and industrial policy.

A more sustainable cuppa: Driving sustainability at Kenyan tea factories

IfM partnered with top tea producer Eastern Produce Kenya to promote simple - but effective - energy-saving practices at two tea estates in the Nandi Hills.

Engineering superheroes: IfM Engage helps aerospace company spread their wings

Yorkshire-based engineering company Produmax, global experts in flight control components and assemblies, credit IfM Engage as crucial in helping them succeed in a volatile global market and build resilience for the future.

Digital transformation on a shoestring

Kate Price Thomas, Shoestring's programme’s Marketing and Engagement Lead, tells us how Shoestring solutions have been deployed in 14 companies, helping them to start to digitalise the low-cost way.

Changing how we talk — and think — about manufacturing

It’s time for a change in how we talk about manufacturing — and that means we must change how we think about it as well, writes Tim Minshall.

Quick win sustainability strategies from the IfM

Insights from the IfM show that rapid sustainability improvements are not only achievable, but can also improve the bottom line.

From grant to scaled-up manufacturing: Roadmapping for success

Learn how roadmapping can support decision making and help get research projects off to the best possible start.

Transforming manufacturing with autonomous supply chains

Digital technologies offer huge opportunities for supply chain transformation. The IfM's Professor Alexandra Brintrup explains how agent-based systems are helping to make supply chains smarter and more efficient.

Digital twins for the space sector

As new space tech companies enter the market, the satellite industry is undergoing a rapid digital transformation. Assistant Professor Dr Veronica Martinez explains how digital twin technology is transforming the satellite industry.

Successful innovation using IoT

Digital transformation is a priority for many manufacturers across the UK. How can manufacturers achieve greater productivity, faster delivery and better customer service through digitalisation?

IfM students help to turn 100-year-old bakery into thriving online business

Despite a few challenging years as a result of COVID-19, 100-year-old Cambridge bakery Fitzbillies has emerged triumphant, with the help and insights of a group of IfM students.

From idea to patient: the IfM approach to healthcare

The IfM has been working on research in healthcare for over 30 years. When the COVID-19 pandemic hit, this meant the institute could respond to new challenges using past experience. Now, the IfM is building on that work across its research and practice.

Lessons for emergency healthcare logistics

IfM PhD student Rob Glew reflects on the lessons learned from two years of working on emergency healthcare logistics during the COVID-19 pandemic.

How can knowledge be shared better across the NHS?

Building on experience from the COVID-19 response, IfM PhD student Carl-Magnus von Behr explains how new research is looking at knowledge sharing across NHS trusts.

Putting new healthcare technology to effective use: wearables for therapeutic cancer treatment

The development of cutting-edge wearable technologies that can monitor people during their cancer treatment is transforming our understanding of the disease and our ability to detect and treat it. But integrating such new technology into care is essential to its effectiveness.

New manufacturing approaches to affordable healthcare

IfM research is exploring how important diagnostics and medical devices can be made more accessible to low- and middle-income countries.

How strategic roadmapping can signpost the route to the future

Roadmapping is a powerful approach that can help organisations to effectively plan and communicate their strategy. Dr Imoh Ilevbare, Principal Solution Development Specialist at IfM Engage, tells Jason Naselli reveals some of the best and most interesting examples he has seen.

The UK Innovation Report 2022

The UK Innovation Report 2022 benchmarks the UK’s industrial and innovation performance in a global context. It brings together innovation and value-added indicators in a concise and accessible format.

Open innovation: Solving IP challenges for SMEs

Dr Frank Tietze, Head of the Innovation and Intellectual Property Management (IIPM) Lab and co-author of a new European Commission report looking at IP and Open Innovation (OI), explains how SMEs can use IP more strategically to gain competitive advantage.

Simpler than it looks: Discovering the Shoestring approach to digital manufacturing

Professor Duncan McFarlane reflects on four years of Digital Manufacturing on a Shoestring, including how he first realised the potential of the approach, and how Shoestring is spreading across Britain and further afield.

EIT Food Accelerator Network provides showcase and support to growing agritech and foodtech ventures

The IfM is in the third year of running the Cambridge hub of the EIT Food Accelerator Network, offering expert mentoring and helping agritech and foodtech start-ups across Europe to increase their chance of becoming commercially and sustainably successful.

What, how and when to automate

Automation can be the answer to a whole host of manufacturing and operations questions. But deciding what, how and when to automate is not straightforward, says Liz Salter at IfM Engage.

Back to the future: Life resumes at Charles Babbage Road

As COVID-19 restrictions ease, we speak to the members of the IfM community about the upcoming academic year, what the ‘new normal’ looks like, and what they’re excited about as they return to the IfM building.

Dr Olivia Remes on the science of wellbeing and mental health

The IfM research associate explains how the adoption of engineering methods can help identify and prioritise interventions in the treatment of depression.

Food allergy incidents are rising. How can food manufacturing improve?

Technology, regulation and a culture of safety all have a role to play as part of a joined-up approach, says Lili Jia.

To remain competitive, aerospace companies need to get digital twins right

As the importance of digital twins grows, most companies still have work to do to fully capitalise on their use.

New low-cost solutions help manufacturers go digital

Cost-effective, off-the-shelf technologies are helping manufacturing SMEs to transform into highly efficient, digitally enabled businesses.

Solar batteries without the charger? We’re working on that

Michael De Volder tells us how a Friday afternoon experiment led to research on a new low-cost battery design that can be charged directly by light without a separate solar cell or power converter.

The future of human-robot interaction: A look at three scenarios

Interaction between robots and humans will become an important feature of the industrial workplace of the future. But what sort of impact will this have on society — and what will that mean for how the technology evolves? The IfM’s Cyber-Human Lab takes a look.

New inkjet printing method could accelerate drug discovery and printed personalised drug delivery

IfM researchers have demonstrated – for the first time – the digital inkjet printing and self-organisation of microdroplets on fluid surfaces to create structures of functional materials.

How 5G technology could unlock new opportunities at ports and across industry

Ajith Parlikad, head of the Asset Management research group at the IfM, tells Jason Naselli about his new research project piloting 5G applications at the port of Felixstowe, and how the potential benefits can boost the UK economy.

In COVID-19 vaccines and economic recovery, supply chains loom larger than ever

Jag Srai explores the biggest global supply chain challenges as we look toward vaccinating the world — and riding out the peaks and troughs of supply and demand as economies reopen.

ARIA and the value of challenge-led innovation

As the UK prepares to launch a new high-risk, high-reward research agency, Eoin O'Sullivan discusses what it can learn from the ARPA model in the US and globally, and why technology and innovation management is the key to success.

Green and beautiful: The benefits of embedding electronics in ceramic tiles

Printing electronics into ceramic building materials could offer a functional and aesthetic way to bring solar energy into structures, and encourage the adoption of environmental sensors in buildings.

The effects of COVID-19 on how universities contribute to innovation

This report – led by the new University Commercialisation and Innovation Policy Evidence Unit with support from the UK National Centre for Universities and Business – investigates the effects of the COVID-19 pandemic on the ability of universities to contribute to innovation through the crisis and into the economic recovery.

UK Innovation Report

The UK Innovation Report benchmarks the UK’s industrial and innovation performance in a global context. It brings together, for the first time in a single place, innovation and value-added indicators in a concise and accessible format.

Business model innovation is key to beating COVID-19 debt

New business models are essential to unlocking the economic growth potential of digital technologies, and offer a way out of rising debt-to-GDP ratios.

Getting the most out of your digital strategy

Nicky Athanassopoulou, Head of Solution Development at IfM Education and Consultancy Services, offers insights into how companies can make the most out of new and emerging technologies.

Confronting complexity: How systems engineering can be applied to healthcare, policy and industry

In this webinar, guest speaker Professor John Clarkson, explains how systems thinking from engineering can be applied to almost any complex challenge, and discuss specific outcomes from his work on the Royal Academy of Engineering project ‘Engineering Better Care’.

The power of repurposing: How smaller manufacturers helped the UK withstand COVID-19’s first wave

As COVID-19 battered Britain’s economy and threatened to overwhelm the NHS, many small- and medium-sized manufacturing firms regrouped, repurposed and provided the vital materials the country needed. How did they do it, and when a new crisis arises, could they do it again?

2020 has emphasised that industrial innovation is vital to Britain’s future

The COVID-19 pandemic has brought renewed attention to the importance of manufacturing. In order to ‘emerge stronger’ from the crisis, the UK must now act more strategically and harness industrial innovation to serve ambitious agendas for the economy and the environment.

Mission critical supply chains: When recall isn’t the best option

When crisis hits and critical products are in short supply, the risk of recalls rises as corners are cut in production. But when these products are needed to save lives, recall isn’t the best option.

The Maker Movement vs COVID-19: How a DIY community responded to the pandemic

The availability of 3D printers, laser cutters and other digital fabrication tools has led to the rise of the Maker Movement, a growing community with a DIY approach to design and production. As the COVID-19 crisis hit the UK, these ‘makers’ sprang into action. Their response has revealed the potential for innovation among the general public — but also the limitations of an informal network and a lack of standardisation.

Learn from the survival of the fittest firms

Manufacturing firms have had a rocky 2020, yet some have not only survived but thrived, re-organising and experimenting with their operations during the pandemic. Jag Srai explains how businesses can learn from the 'survival of the fittest firms'.

Developing a ventilator sharing device for use in emergencies

In this webinar, experts from the IfM, Royal Papworth Hospital and Cambridge Design Partnership discuss how they developed a device that, if needed in an emergency, could be attached to a ventilator to enable two COVID-19 patients to receive tailored respiratory support.

Manufacturing a better world after COVID-19

Tim Minshall, Dr John C Taylor Professor of Innovation and Head of the Institute for Manufacturing, shares an overview of how teams of Cambridge engineers have helped the local, national and international response to the COVID-19 pandemic, and how we can use the lessons learned to support a strong and sustainable recovery.

How manufacturing can emerge stronger: Policies to support industrial recovery and growth after COVID-19

This briefing note examines key policy instruments aimed at supporting the recovery and future growth of manufacturing industries in the wake of COVID-19.

How IfM students helped the NHS in Cambridge during COVID-19

Three teams of students from the MPhil in Industrial Systems, Manufacture and Management course at the Institute for Manufacturing worked with the NHS on issues including testing processes, oxygen supply mapping and patient flow modelling during the COVID-19 outbreak.

Test, Tag and Trace - A digital solution to get organisations back to work, safely

This webinar gives an overview of research demonstrating how organisations can use widely available, low-cost technology to provide greater protection to employees as they return to work.

Patient-flow modelling and resource demand prediction during COVID-19

This webinar provides insights based on the experience and modelling efforts of Addenbrookes Hospital, based in Cambridge (UK), to predict local hospital admissions, model patient flows through the hospital and estimate subsequent use of resources.

Manufacturing plays a vital role in creating a truly sustainable world by 2050

Seven years ago, Professor Steve Evans helped to write a major report for Whitehall on the future of British manufacturing and sustainability. In the wake of COVID-19, he looks back on the predictions and what the future looks like today for policy makers and executives.

Test, Tag and Trace: A digital solution for getting back to the office safely

As people across the UK gradually return to offices, a widely available, low-cost technology can help business protect their employees and ensure a COVID-safe workplace, write Dr Veronica Martinez and Dr Mahsa Honary.

Top tips to get your firm fighting fit post-COVID

Leading experts advise how businesses can best prepare for the months and years ahead, and any future disruption that may come.

Manufacturing sustainability: Back to the future

In this webinar Steve Evans revisits the 'Future of UK Manufacturing' predictions from 2013 and looks ahead to the big changes and challenges that are now shaping our industrial future.

COVID-19: Manufacturing at a turning point

At this IfM Briefing, leading experts from the Institute for Manufacturing draw lessons from the response of firms and governments to the COVID-19 pandemic, and look at how the manufacturing industry is likely to change and adapt in the months and years ahead.

Can policy simulations help developing economies after COVID-19?

In the wake of the economic jolt of the coronavirus, Nazia Habib explains how policy simulation labs can help developing economies chart a path to recovery.

COVID-19 and the global contraction in FDI

The COVID-19 pandemic is causing massive disruptions to flows of foreign direct investment. Jostein Hauge and Adnan Seric explain why developing countries are likely to be hit the hardest.

Supply chains and the power of artificial intelligence

Artificial intelligence offers huge potential for supply chains, but there are a lack of practical examples to demonstrate how data-driven approaches can be implemented effectively. Alexandra Brintrup explains how her research addresses this gap, and reveals valuable lessons for organisations.

UK supply chains: Learning the right lessons from COVID-19

Carlos López-Gómez addresses the myths surrounding the weakness of UK supply chains in the coronavirus crisis, and explains what must be done for UK supply chains to emerge stronger.

Steering your organisation through a time of uncertainty

In this webinar, experts from the IfM cover how organisations can use strategic tools including roadmapping and scenario planning to plan in a rapidly changing business landscape.

Virtual workshops: Top tips for remote collaboration

IfM in-house facilitators Dr Imoh Ilevbare and Dr Diana Khripko share their experience and insights on how they design online workshops that achieve the desired outcomes for our partners.

COVID-19 critical supplies: The manufacturing repurposing challenge

Amid the COVID-19 emergency, policy makers are calling for manufacturing firms to temporarily repurpose their production to make critical supplies such as masks, ventilators and test kits. Building on a recent study from the Policy Links Unit, this article reviews some of the challenges involved in repurposing and potential ways to mitigate them.

Connecting healthcare and manufacturing: The challenges of COVID-19

Tim Minshall, head of the IfM, looks at the many challenges of matching offers of support from the manufacturing community with the dynamic and uncertain needs of the healthcare system.

Structured decision making in uncertain times: An IfM approach

Kate Willsher, COO of IfM Education and Consultancy Services, presents a rapid method developed at the Institute for Manufacturing to assess the opportunity and feasibility of new business initiatives.

Could intellectual property concerns slow the response to COVID-19?

A new paper from IfM and University of Cambridge researchers explores how to avoid IP-related delays in the pandemic response.

Innovate Indonesia: Unlocking growth through technological transformation

This study, developed by the IfM's Policy Links Unit for Indonesia's Ministry of Finance and the Asian Development Bank, explores policy options to facilitate Indonesia’s technological transformation and unlock its economic growth potential.

What does lockdown mean for the future of our food supply?

Supply chain collaboration at local and international levels will be crucial in the months ahead, but ultimately COVID-19 will result in a rethinking of our reliance on global supply chains, in favour of more resilient and more local production.

Understanding risk in pharmaceutical supply chains

This executive briefing, an output from the ReMediES (Reconfiguring Medicines End-to-end Supply) project, covers key elements of supply chain risk specifically linked to the management of pharmaceuticals.

The future of the manufacturing workforce

This report shares insights from a recent roundtable discussion convened by the Babbage Forum exploring the future of the manufacturing workforce, with perspectives from OECD, UNIDO, UNCTAD and the World Economic Forum.

The power of AI for supply chain efficiency

Dr Alexandra Brintrup shares key learnings from recent practical examples demonstrating how AI and data analytics can be used in supply chains to reduce disruption and improve efficiency.

Helping SMEs towards digitalisation

Professor Duncan McFarlane provides an update on the progress of this high-profile project, developing low-cost digital solutions for SME manufacturers, with examples of some of the components developed so far.

Training the manufacturing leaders of the future

Student industry projects in host companies are a central component of the IfM's education programmes. Dr Judith Shawcross explains how and why these projects provide such strong skills development.

Digital manufacturing: opportunities and barriers

Dr Carlos López-Gómez and Dr David Leal-Ayala from the IfM’s Policy Links Unit discuss international evidence on the opportunities and barriers to capturing value from digital technologies in manufacturing.

Do you really know what you’re eating?

Supply chain transparency and traceability is becoming essential in the food sector, but how can companies create value from this necessity? Dr Mukesh Kumar and Rob Glew share a case study on a transformative initiative by AMT Fresh.

Ecosystem thinking for strategic planning [WEBINAR]

In this webinar Florian Urmetzer explores how looking to your business ecosystem can offer opportunities to draw in the resources and capabilities needed to meet the demands of end-customers.

Driving competitive advantage through transformative technologies

Dr Jag Srai and Dr Paul Christodoulou provide insights into the Digital Supply Chains Consortium's work, including developing decision criteria for incremental or radical transformations.

How sustainable are our online food shopping baskets?

E-commerce has completely changed the way we shop. But how sustainable is it? We interviewed Dr Jag Srai to find out more about the impact of online food shopping.

OK Computer?

This study aims to promote better knowledge of the safety and security risks and requirements deriving from the Fourth Industrial Revolution (4IR) in order to design concrete implementation plans for industry stakeholders to adopt 4IR technologies confidently through pilot studies.

IP strategy: from innovative ideas to viable businesses

Intellectual property (IP) is a major asset for most companies, from entrepreneurial ventures through to multinationals. Dr Frank Tietze unpicks IP strategy development for start-ups and growing companies.

Digital manufacturing on a Shoestring

In this article, Professor Duncan McFarlane introduces a new research project into low-cost digital solutions for manufacturing SMEs.

New industrial capabilities for new economic growth

The objective of this report is to inform policy efforts, aimed at promoting industrial innovation and competitiveness, by providing insights into international policy practices and approaches. The report discusses key concepts and definitions relevant to understanding the role of domestic suppliers in modern industries, reviews programmes and initiatives in selected countries, and suggests policy implications for the UK.

- 3D printing

- Advanced manufacturing

- Automation

- Big Data and the new analytics

- Business model innovation

- Business strategy & performance

- Business tools

- Design for transformation

- Developing people

- Digital manufacturing

- Ecosystem mapping

- Education

- Global supply chains

- Innovation and IP management

- Managing risk

- Manufacturing a better world

- Manufacturing matters

- Open Innovation

- Roadmapping

- Servitization

- Strategic asset management

- Sustainability

- Technology and innovation policy

- Technology management

- Healthcare