Virtual Intelligent Production, Procurement and Prediction

Overview

Manufacturers face significant challenges with suppliers supporting manufacturing operations: if a supplier does not deliver an assembly or component on time and at the right quality, then the impact to production can be significant and costly. Many manufacturers deal with hundreds of shortages per day for a variety of reasons such as being overloaded by orders from other customers, day-to-day delays during transportation of goods, and suppliers not being able to satisfy manufacturing demand.

The Virtual Intelligent Production, Procurement and Prediction (VIPr) project, working with The Boeing Company, aims to address these issues by developing a system utilising data analytics to make predictive interpretations about potential supplier operational disruptions.

Challenges for manufacturers

Large manufacturers can have enormous numbers of parts shortages per day, for a variety of reasons:

- suppliers being overloaded by orders from other customers,

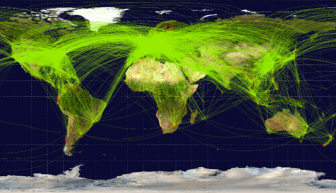

- day-to-day delays during transportation of goods,

- suppliers not being able to satisfy manufacturing demand.

These can result in significant production delays.

Questions

- How can the capacity of a supplier be determined?

- How can supplier failures be predicted using both public and internal data?

- How can manufacturers gain further visibility of the sub-tiers?

Addressing the Challenges

The Virtual Intelligent Production, Procurement and Prediction (VIPr) project aims to address these issues by:

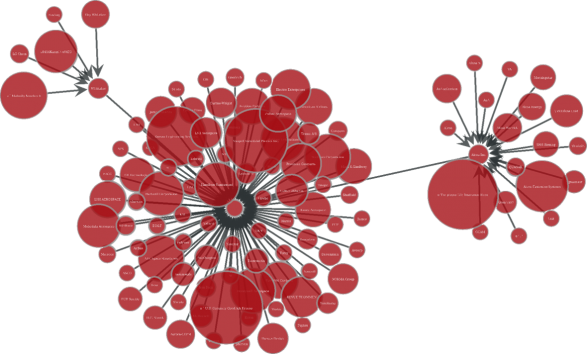

- Using public data to model the supply chain.

- Developing a system utilising data analytics to make predictive interpretations about potential supplier operational disruptions.

Principal Investigator

Researchers

Project Partner

The Boeing Company