Leaning on production

What trigger is the company responding to?

Environmental protection is one of Toyota’s 'Guiding Principles', first issued in 1992, and further documented in the Toyota Earth Charter. Using these documents as a blueprint for action and applying their management tools, including The Toyota Way and The Toyota Production System, each region developed a series of five-year action plans. These plans set challenging targets to continually reduce environmental impact and were disseminated to all levels of each plant. Toyota Motor Europe (TME) are now part way through the 4th five-year action plan.

What was the response?

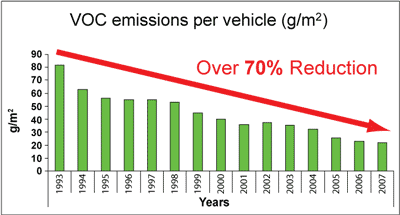

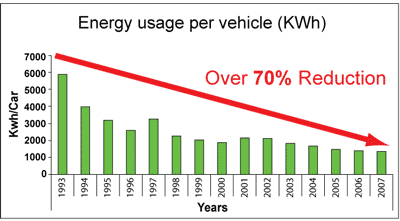

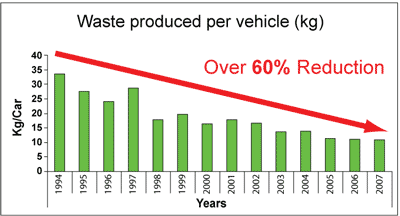

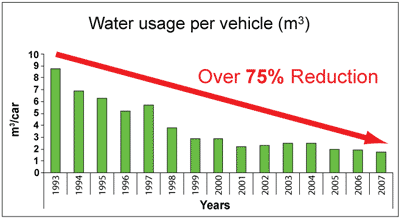

Taking the global aim of zero emissions and a roadmap towards the ultimate eco car as inspiration for the manufacturing companies in Europe, TME developed their own vision 'Towards the ultimate eco factory'. This vision was based upon a strong foundation of legal compliance and risk reduction, with special focus on four major key performance indicators: energy/CO2, water, waste and air emissions (Volatile Organic Compounds – VOC). These represent the most significant manufacturing plant environmental impacts.

Bottom line benefits

By adopting these principles the European manufacturing environmental impact was significantly reduced. In many areas significant cost savings have also been realised. Toyota UK (TMUK) demonstrates this continual improvement since 1993 (see graphs).

Some practical examples of TMUK's activities and achievements:

- Zero waste to landfill - achieved in 2003 (two years ahead of target)

- Waste water recycling - 100,000 tonnes of water saved per year

- CO2 reduction within the boiler house (4,500 TC02e per year below 2004 levels)

- Decoupling of CO2 emissions with increasing production volumes since 2003

- 25% reduction in energy use per vehicle in paint booths.

Wider lessons

TMUK and a plant in France, were selected as two of five global Toyota 'sustainable plants' which serve as best practice development models for the Toyota organisation. These plants focus on achieving leading environmental performance, increasing the use of renewable energies and ensuring the plants are in harmony with their local surroundings. Toyota also contributes to a wider audience by sharing information and activity with a wide range of interested parties.

Case study sources

Sustainable Manufacturing - Presentation to International Manufacturing Professors Conference, Steve Hope, Toyota Motor Europe, July 2008

Toyota Sustainability Report, Toyota Motor Europe, 2007

Case study provided by Steve Hope, Toyota Motor Europe