Beyond sugar to tomatoes, bio-ethanol and more...

What trigger is the company responding to?

Anticipated changes to the European Union (EU) Common Agricultural Policy and the need to stay competitive within the EU, inspired the company to evaluate step changes in its manufacturing approach. After consolidating plants and expanding capacity at its Wissington facility, and with support from its parent company, Associated British Foods, they successfully implemented a combined heat and power plant. This simultaneously increased the factory’s financial efficiency and its capacity to expand beyond sugar production.

What was the response?

The success of initial investments at Wissington encouraged British Sugar to seek further opportunities to improve the efficiency and resilience of its manufacturing operations. According to industry reports [1] British Sugar is the most efficient beet processor in Europe, running a longer production campaign than most EU sites, operating capital intensive assets for longer and at higher efficiencies. As part of this advanced manufacturing strategy

the company works closely with its growers to improve beet quality and productivity, for example by sampling produce and providing feedback direct to the farmers. This helps maximize sugar yield an

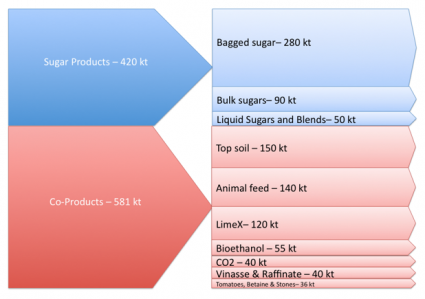

d reduce pesticide, phosphorus and nitrogen inputs across the whole supply chain. Alongside these efforts British Sugar looked to exploit all available resources (e.g. soil, waste heat/CO2) through their “opportunity thinking” which saw all materials as potentially valuable, thereby developing new lines of business, expanding into tomatoes and bio-ethanol production.

Bottom line benefits

Revenues are generated by the sale of co-products, and costs are avoided by sending less material to landfill. Each new project must deliver a return on investment. Wissington is the most efficient beet producer in Europe.

Wider lessons

Core business innovations help the company remain competitive, whilst the development of co-product lines provides a diversified supplementary income. The “opportunity thinking” culture is apparent throughout the organization; those with the process knowledge being empowered to identify the innovations to be taken forward. The “waste nothing” attitude also appears to have transferred seamlessly across the new businesses. The company reputation in this area also helps with recruitment. Collaboration with suppliers has been a hallmark of many of the improvements; from working with farmers to improve yield, optimise fertilizer use and extend the producing season, to collaborating with GE to optimise the operation of its CHP gas turbine. Careful consideration of when to partner, when to bring expertise in, and when to outsource new co-product operations has also underpinned the development of new lines of business. Scale is important in this example. Smaller operations may have to combine streams, or if waste streams variability is high then the secondary processing plants might not be viable.

Sources & references

Data collected from AB Sugar during interviews and discussion with Richard Ali, Gary Punter & staff, also AB Sugar Marketing Materials.

Source [1] Supplied by AB Sugar, taken from LMC International, Beet Sugar Production Costs 2012 SustainValue case study material

Acknowledgements

The work resulting in this case study was in part funded by British Sugar. The University of Cambridge retained editorial control of the content of the study presented herein.

More Information

Request to read the research paper 'From refining sugar to growing tomatoes' on researchgate.net.