Roadmapping at BASF

BASF is one of the world’s leading chemical companies. It has around 113,000 employees and annual sales in the region of €75 billion. Its products are used by businesses in virtually every country around the globe.

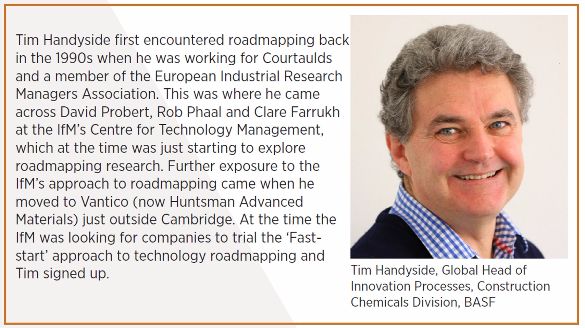

Tim Handyside, Global Head of Innovation Processes in BASF’s Construction Chemicals Division, met Clare Farrukh, Senior Research Associate at the IfM’s Centre for Technology Management (CTM) to discuss the benefits of roadmapping and some of the challenges companies experience when trying to maintain its momentum within an organisation.

Introducing roadmapping to BASF Construction Chemicals

When Tim became head of a new innovation management group for BASF’s Construction Chemicals Division in 2011 he was already an advocate of roadmapping. The creation of the new group reflected the Construction Chemicals Division’s shift from a structure in which regions operated as more or less autonomous business units to one which took a more global approach to strategic business management. Global business segments were developed with ‘Segment Portfolio’ teams which brought together researchers, product developers, marketing and business development people. From his experience in previous roles, and his contact with the IfM’s CTM over the years, Tim knew that roadmapping was an ideal tool to help these cross-disciplinary teams develop and maintain a successful product and technology pipeline as part of the ongoing strategic planning cycle. This approach had the full approval of both the division’s senior and global business management.

“If a business is dealing with a lot of tactical day-to-day issues worrying about the pipeline is difficult. But that is the name of the game. You have to think tactically and strategically.”

An integrated approach

To deliver long-term benefits roadmapping needs to be much more than a one-off exercise. If it was going to underpin the creation and implementation of the Division’s product and technology strategy on a rolling basis, it would need to be become a key part of the planning process and be thoroughly ‘institutionalised’ into the DNA of all those involved. To help make this happen, the IfM was invited to run several training workshops with wideranging cross-functional groups and with some members of Tim’s team learning the facilitators role. From there, the division has continued to run the process itself.

|

Tim is convinced of the merits of what he calls the ‘Cambridge School’ of roadmapping – a fully integrated approach which aligns the market, product and technology requirements with the business strategy while maintaining a large scope for creative inputs. It is distinct from those roadmaps which deal solely with technology and research pathways. He said: “I can’t understand how organisations live without it. A roadmap can add immense value in many different ways, particularly in the integrity and credibility of product and technology plans and directly for the people doing the technical work – it helps them to see, communicate and substantiate their position as to why they are doing what they are doing.” Roadmapping is also a powerful diagnostic tool. White spaces become very apparent, drawing attention to areas lacking in product and technology plans or other weak areas of business intelligence. One of the most compelling reasons for using roadmapping is its role as a ‘boundary object’. This is a sociological concept used to describe something with which lots of people can interact and which they may even interpret differently but which nonetheless is able to maintain its essential meaning. Tim explained: “To help teamwork and group processes work efficiently and effectively, it is important to have such objects and a plan that give people a context and reference points. This will, if anything, become even more important as industrial behaviours change with, for example, the creation of virtual global teams, as the role of management evolves and as hierarchies become flatter. Road maps act as very useful boundary objects and are sufficiently robust to cope with staff changes or movement.”

However, while the organisation is convinced of the benefits of roadmapping and has made significant progress in institutionalising it over the last four years, there have been some challenges along the way. When Tim met Clare they discussed some of these issues and compared them with the experiences reported to Clare by members of CTM’s Strategic Technology and Innovation Management (STIM) consortium.

Challenges at BASF – and elsewhere

Tim: I find it surprising that there are still some people who don’t ‘get’ roadmapping.

Clare: For some people it can be uncomfortable to have transparency, something that represents the state of your thinking. We also see technology people who are worried about being held to account for statements that may be inherently uncertain. Roadmapping can make people feel exposed. It is also an ‘emergent strategic process’ which is, by its very nature, essentially democratic – something that does not always sit easily with an organisation’s culture.

Tim: Roadmapping is taking longer than I had hoped to fully institutionalise even though there is plenty of organisational support for it. And I think there are some interesting reasons for that. In our portfolio segment teams we have two big face-to-face meetings a year for which people travel in from around the globe. Roadmapping is always on the agenda but so are a lot of other important items so while it has become embedded in our team processes it is a challenge to keep it as a high priority.

Clare: This is a big question which many organisations face – knowing how most effectively and efficiently to refresh the roadmap. It often doesn’t make sense to run a full-scale, two-day workshop every six months particularly if there hasn’t been any significant change to the internal and external environment.

Tim: That is certainly an issue for us. The drivers for change don’t change that fast for us. The counter argument is that potentially things could change faster if we were generating more new ideas which were driving change.

|

Clare: If a business is dealing with a lot of tactical day-to-day issues worrying about the pipeline is difficult. But that is the name of the game. You have to think tactically and strategically. One of the issues that has emerged from our conversations with other companies is the challenge of dealing with the aftermath of a roadmap. Companies can be left with a forest of post-it notes which need to be transcribed and the material structured and presented in a way that is useful. That takes time and effort.

Tim: We certainly recognise that challenge. We spend a lot of time putting it all into Excel and then work on the quality of the visualisation material. Although it does take quite a lot of effort, it is worth doing well. Another challenge we have is around timescales and scope. As part of the pre-workshop preparations – particularly if we are running workshops outside of the core process – we ask people how far ahead they want to think, how deep they want to go and which business they want to focus on. These different dimensions of setting up the workshop can be difficult.

Clare: This is something else we see. When people are roadmapping a new area they can trip over because the focus is too narrow or too wide.

Tim: We also struggle with going from the ‘landscape’ to the ‘landmark’. We have got to the point where people are happy to produce a landscape within the workshops but we have had less success to date in taking ideas down to the topic level within the workshops. This is partly due to available time.

Clare: In fact, we have developed a light-weighted toolkit approach to do exactly that. It incorporates both focused roadmapping templates and a simple portfolio planning tool that can help dig down into good opportunities.

Tim: Another area we have considered is bringing customers or other external stakeholders into the process as early as possible.

Clare: We have seen that used very successfully across supply chains in sectors such as aerospace and automotive where there are lots of tier 1 and 2 suppliers. It is definitely worth thinking about.

“I can’t understand how organisations live without it. A roadmap can add immense value in many different ways particularly in the integrity and credibility of product and technology plans and directly for the people doing the technical work – it helps them to see, communicate and substantiate their position as to why they are doing what they are doing.”

Many of the challenges encountered by BASF’s Construction Chemicals Division resonate with those experienced by members of the IfM’s STIM Consortium. The benefits of roadmapping are clear but how can those people charged with institutionalising it make sure those benefits are fully realised?Observations from IfM research

The preliminary results of Clare’s research project suggest a number of ways in which organisations can address some of these challenges.

A roadmapping workshop for BASF’s Construction Chemicals Division

Take part in the STIM research project

Clare Farrukh is a Senior Research Associate in the IfM’s Centre for Technology Management. She is leading a research project on ‘Roadmapping – embedding the process’ as part of the IfM’s Strategic Technology and Innovation Management (STIM) Consortium, a practice-oriented research and networking collaboration between industrial member companies and the Centre for Technology Management. The objective of the STIM project during 2016 is to identify key issues, share good practice and work towards developing a maturity model for roadmapping. As part of this, she is looking for companies interested in helping to develop a roadmapping maturity model as a structured and flexible framework to capture challenges and good practice solutions.

STIM companies will be encouraged to provide ongoing feedback on their roadmapping work, to host pilot workshops, contribute to and comment on emerging guidance and to take part in open events. Organisations that are not current STIM members will be invited to these open events so that ideas can be exchanged with a wider range of companies.

To find out more about this research, to become a STIM member or to participate in the ‘Embedding the process’ open forums, contact Clare Farrukh E: cjp22@cam.ac.uk

More articles from IfM Review Issue 5

'A social network of things' - New approaches to asset management

'A social network of things' - New approaches to asset management

The Cambridge Value Mapping Tool

The Cambridge Value Mapping Tool

IfM Review Issue 5 Articles

|

'A social network of things' - New approaches to asset management |

|

The innovation game

The innovation game

Liquid assets

Liquid assets Roadmapping at BASF

Roadmapping at BASF Bridging the gap

Bridging the gap Manufacturing Leaders

Manufacturing Leaders