The Impact of Novelty on Ramp-up Manufacturing

Background

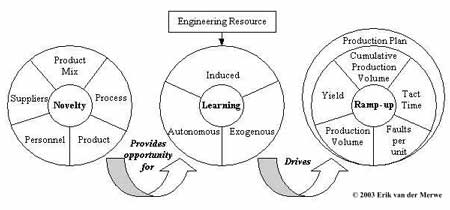

Novelty in various guises drives the performance improvement curve that is observed during the initial introduction of new products into manufacturing. The management of the introduction of both new process technology and new products into manufacturing presents a serious challenges to companies. This research project is developing a framework using the concept of learning to link novelty to this performance curve drawing on the literature and also on various case studies. Although the literature specifically pertaining to initial commercial, or ramp-up, manufacturing is sparse there is a consensus in academia and industry that this period is crucial to many product's success. The framework development therefore draws heavily on the numerous studies of new product introduction, learning and manufacturing, and the impact of design on manufacturing.

Aim

The aim of this research is to develop a conceptual framework describing how novelty impacts ramp-up manufacturing performance.

Objectives

- To develop a framework capturing the factors which are indicative of the impact of a new product and its associated novelty on the manufacturing operation.

- To construct a management tool based on the framework which will aid companies in better managing their response to the novelty introduced with a new product.

Conceptual Framework

The conceptual framework is continually being refined as information about the mechanism through which novelty impacts manufacturing is gleaned from the case study data. Here it is presented in its current form.

Case Study A

The case considers a new product platform introduced into three new production lines starting up next to two existing lines, which are eventually replaced by the new lines. All five dimensions of novelty as presented in the framework above directly impact manufacturing performance. The results from Case Study A have been summarised in terms of the novelty, learning and ramp-up performance concepts contained in the conceptual framework and are listed in the following table. The problems introduced through the five novelty dimensions are listed in the novelty column, thereafter the learning response of the organisation and finally the impact on the ramp-up performance.

|

Product |

Induced Learning |

Ramp-up Performance |

|

|

|

|

Process |

Induced Learning |

Ramp-up Performance |

|

|

|

|

Product Mix |

Induced Learning |

Ramp-up Performance |

|

|

|

|

Supplier |

Induced Learning |

Ramp-up Performance |

|

|

|

|

Personnel |

Induced Learning |

Ramp-up Performance |

|

|

|

|

Autonomous Learning |

||

|

Researchers

- Erik van der Merwe

- Gerry Frizelle

Glossary

Ramp-up Manufacturing Period: The period of initial commercial manufacture of a new product until volume production is achieved.

Publications

- "A framework for manufacturing ramp-up", presented at PICMET 2003 international conference in Portland, Oregon. This paper discusses the initial derivation and validation of the conceptual framework.

- "Novelty as driver of manufacturing performance: A case study", presented at EurOMA-POMS 2003 conference in Como, Italy. This paper contains a ramp-up manufacturing case study and its impact on the conceptual framework.

- "The complexity of novelty in ramp-up manufacturing", presented as invited paper at Design Complexity Meeting of the Manufacturing Complexity Network in Milton Keynes, UK.

Useful papers

- Adler, P. S. (1995) " Interdepartmental interdependence and coordination: the case of the design/manufacturing interface", Organization Science Vol. 6 No. 2, pp.147-167.

- Alchian, A. (1963) "Reliability of Progress Curves in Air-frame Production", Econometrica Vol. 31, pp. 679-693.

- Almgren, H. (2000) "Pilot production and manufacturing start-up: the case of Volvo S80", International Journal of Production Research Vol. 38 No. 17, pp. 4577-4588.

- Booz, Allen and Hamilton (1982) "New product management for the 1980’s", Booz, Allen and Hamilton, Inc., New York.

- Boston Consulting Group (1972) "Perspectives on Experience", BCG, Boston.

- Clark, K. B. and Fujimoto, T. (1991) "Product Development Performance", Harvard Business School Press, Boston, MA.

- Cooper, R. G. (2000) "Doing It Right", Ivey Business Journal Vol. 64 No. 6, pp.54-60.

- Daft, R. L. and Lengel, R. H. (1986) "Organizational Information Requirements, Media Richness And Structural Design", Management Science Vol 32. No. 5, pp. 554-571.

- Day, G. S. and Montgomery, D. B. (1983) "Diagnosing the Experience Curve", Journal of Marketing Vol. 47 No. 44, pp. 44-58.

- Dutton, J. M. and Thomas, A. (1984) "Treating Progress Functions as a Managerial Opportunity", Academy of Management Review Vol. 9 No. 2, pp. 235-247.

- Frizelle, G. D. M. and Gregory, M. J. (2000) "Complexity and the impact of introducing new products", Proceedings of the Conference on Complexity and Complex Systems in IndustrySeptember, University of Warwick, Coventry.

- Galbraith, J. R. (1977) "Organizational Design", Addison-Wesley, Reading, Mass.

- Guetzkow, H. and Simon, H.A. (1955) "The impact of certain communication nets upon organization and performance in task-oriented groups", Management Science Vol. 1 No. 3, pp. 233-250.

- Hatch, N. W. and Mowery, D. C. (1998) "Process Innovation and Learning by Doing in Semiconductor Manufacturing", Management Science Vol. 44 No. 1, pp. 1461-1477.

- Hirsch, W.Z. (1956) "Firm Progress Ratios", Econometrica Vol 24 No. 2, pp 136-143.

- Leavitt, H.J. (1951) "Some effects of certain communication patterns on group performance", Journal of Abnormal and Social Psychology Vol. 46, pp. 38-50.

- Levin, D.Z. (2000) "Organizational Learning and the Transfer of Knowledge: An Investigation of Quality Improvement", Organization Science Vol. 11 No.6, pp. 630-647.

- Levy, F.K. (1965) "Adaptation in the Production Process", Management Science Vol. 11, pp. B136-B154.

- Miles, M. and Huberman, M. (1984) "Qualitative Data Analysis", Sage Publications, London.

- Mishina, K. (1999) "Learning by New Experiences: Revisiting the Flying Fortress Learning Curve", in Lamoreaux, N., Raff, D. M. G. and Temin, P. (eds), Learning by Doing in Markets, Firms, and Countries, University of Chicago Press, Chicago.

- Perrow, C. (1967). "A Framework for the Comparative Analysis of Organizations." American Sociological Review Vol. 32, pp. 194-208.

- Pisano, G. P. (1997) "The Development Factory", Harvard Business School Press, Boston, MA.

- Sheshinski, E. (1967) "Tests of the Learning by Doing Hypothesis", Review of Economics and Statistics Vol. 49, pp. 568-578.

- Susman, G. I. and Dean, J. W., Jr. (1992) "Development of a model for predicting design for manufacturability effectiveness", in Susman, G. I. (ed.), Integrating Design and Manufacturing for Competitive Advantage, Oxford University Press.

- Stalk, G., Jr. (1988) "Time &endash; The Next source of Competitive Advantage", Harvard Business Review July-August, pp. 41-53.

- Terwiesch, C. and Bohn, R. E. (2001) "Learning and Process Improvement during Production Ramp-Up", International Journal of Production Economics Vol. 70 No. 11, pp. 1-19.

- Terwiesch, C., Chea, K. S., and Bohn, R. E. (1999) "An Exploratory Study of International Product Transfer and Production Ramp-Up in the Data Storage Industry", The Information Storage Industry Center Report 99-02.

- Thorndike, E. L. (1898) "Animal Intelligence: An Experimental Study of the Associative Processes in Animals", The Psychological Review: Monograph Supplements Vol. 2, pp. 1-109.

- Thurstone, L. L. (1919) "The Learning Curve Equation", Psychological Monographs Vol. 26, pp. 1-51.

- Wheelwright, S. C. Clark, K. B. (1992), "Revolutionizing Product Development", The Free Press, New York.

- Wright, T. P. (1936) "Factors Affecting the Cost of Airplanes", Journal of Aeronautical Science Vol. 3 February, pp. 122-128.