AI in Manufacturing

The IfM 'Manufacturing Horizons' webinar series will cover the transformative potential of AI and its role within the broader context of manufacturing.

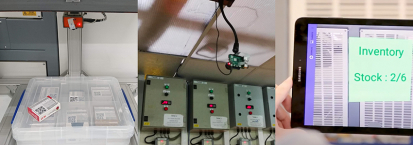

New low-cost solutions help manufacturers go digital

Cost-effective, off-the-shelf technologies are helping manufacturing SMEs to transform into highly efficient, digitally enabled businesses.

Test, Tag and Trace: A digital solution for getting back to the office safely

As people across the UK gradually return to offices, a widely available, low-cost technology can help business protect their employees and ensure a COVID-safe workplace, write Dr Veronica Martinez and Dr Mahsa Honary.

Helping SMEs towards digitalisation

Professor Duncan McFarlane provides an update on the progress of this high-profile project, developing low-cost digital solutions for SME manufacturers, with examples of some of the components developed so far.

Strategic planning for digital transformation [WEBINAR]

In this webinar Dr Rob Phaal explores the practice of strategic roadmapping and how it could be applied to support digital transformation in an organisation.

Digital manufacturing, on a shoestring budget [WEBINAR]

This webinar introduces Digital Manufacturing on a Shoestring, an EPSRC-funded project, that aims to demonstrate how low-cost commercially available technologies can be exploited in SMEs.

Digital manufacturing: opportunities and barriers

Dr Carlos López-Gómez and Dr David Leal-Ayala from the IfM’s Policy Links Unit discuss international evidence on the opportunities and barriers to capturing value from digital technologies in manufacturing.

Driving competitive advantage through transformative technologies

Dr Jag Srai and Dr Paul Christodoulou provide insights into the Digital Supply Chains Consortium's work, including developing decision criteria for incremental or radical transformations.

The practical impact of digital manufacturing

Governments in a number of countries have made investments in digital manufacturing. Are there yet signs of resulting upturn in productivity, gross value added, or employment? A new report from Policy Links considers the evidence.

Industrial Internet of Things - Connected Everything

As part of the Connected Everything project, at the University of Nottingham, Professor Duncan McFarlane championed the thematic research on the Industrial Internet of Things creating a report which is available to download.

Digital manufacturing on a Shoestring

In this article, Professor Duncan McFarlane introduces a new research project into low-cost digital solutions for manufacturing SMEs.

The practical impact of digital manufacturing: results from recent international experience

This report by Policy Links for Innovate UK analyses evidence on potential benefits derived from the adoption of digital technologies in the manufacturing sector.

Introduction to the Industrial Internet of Things (IIoT)

Professor McFarlane talks about the next stage in the IoT evolution and its expansion into industry (IIoT).

Why you need Big Data to measure customer loyalty

Dr Mohamed Zaki discusses the pitfalls of relying on simplistic numerical values to measure customer loyalty.

Intelligent assets for the infrastructure of the future

IfM's Professor Duncan McFarlane (Head of DIAL) and Ajith Parlikad (Head of Asset Management) have co-authored an ICE (Institution of Civil Engineers) Guidance Paper on how new technologies will transform the infrastructures of the future.

The digitalisation of manufacturing economies

New digital technologies are radically changing the ways firms manufacture products, the business models they adopt, and even how they innovate. At a national level, digital technologies promise to reshape national manufacturing systems and redefine sources of competitive advantage.

Getting the most out of automation

Alan Thorne describes some of the work of the IfM's Distributed Information and Automation Laboratory (DIAL) and how it can help companies improve their automation systems.

Manufacturing leadership in the age of digital disruption

Professor Andy Neely, Head of the IfM and the Cambridge Service Alliance, on how industry leaders should focus on five key areas if they want to survive the journey to a digital future.

How bright is your digital future: digitalising the extended supply chain

Dr Jag Srai, Head of the IfM's Centre for International Manufacturing (CIM), and his team have developed a new way to help companies embrace the challenges and opportunities of digitalising the extended supply chain.

Application of digital technologies to innovation in manufacturing

This report, commissioned by BSI (British Standards Institute), looks at how standards and good practice can help the UK benefit from the 'digital revolution'.

Getting smart with digital

The speed at which technologies are now evolving and computational power is increasing means that digital manufacturing is now coming of age and with it widespread innovation and disruption.

Big and clever: a system-wide approach to data analytics

The Distributed Information and Automation Laboratory (DIAL) at the IfM are working with companies such as Boeing, Exxon, Electrolux and Laing O'Rourke to develop smart ways of using data to improve performance and increase resilience.

A social network of things - New approaches to asset management

Dr Ajith Parlikad, Head of the IfM's Asset Management Group, explains how effective asset management can deliver significant value both for manufacturers and for infrastructure owners and operators.

Connecting the unconnected: New thinking on next generation supply chains

As the annual Cambridge International Manufacturing Symposium marks its twentieth year Dr Tomas Harrington, Dr Jag Srai and Paul Christodoulou from the IfM's Centre for International Manufacturing (CIM) reflect on the new supply chain thinking that is emerging from companies such as Cisco, Coca-Cola, Jaguar Land Rover, Johnson Matthey, Cambridge University Press and Schneider Electric.

DIAL B for Boeing

Duncan McFarlane, Head of the IfM's Distributed Information & Automation Laboratory (DIAL), and members of his research team have been working with Boeing since 2005, finding intelligent solutions to some challenging industrial problems.

Digital futures - and other manufacturing matters

Digitalisation - everyone is talking about it but what does it mean in practice for industry and government. On 12 May, the IfM held its annual Briefing Day, attended by more than 150 senior industrialists and policymakers.

Expecting the Unexpected

The key to long-term management of infrastructure lies in futureproofing, say Duncan McFarlane and Tariq Masood.

The Origin of the Internet of Things

Most of you have probably heard the Internet of Things, or the IoT, mentioned but have you ever wondered what it means and where it all began?

What makes an intelligent infrastructure asset?

What would it take to enable a piece of infrastructure to take care of itself, asks Duncan McFarlane of the Cambridge Centre for Smart Infrastructure?

How can big data create value for companies?

Dr Mohamed Zaki describes recent research from the Cambridge Service Alliance into data-driven business models.

Total Information Risk Management: Maximizing the Value of Data and Information Assets

How well does your organization manage the risks associated with information quality?