IfM researchers create ground-breaking ultraflexible battery

Researchers from the IfM’s NanoManufacturing group have created an innovative carbon nanotube structure which allows them to create extremely flexible batteries with superior performance.

While there is a clear trend in the market for flexible devices – from consumer electronics such as tablets and mobile phones to medical implants, radio-frequency identification (RFID) tags and displays – the batteries which power them are still too heavy, bulky and rigid. This is due to the difficulty of creating a truly flexible product which does not break, crack or lose functionality when repeatedly bent.

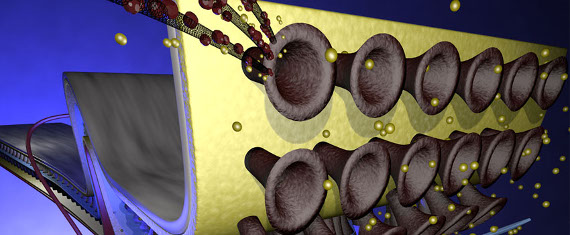

However, the NanoManofacturing research team composed of Drs Shahab Ahmad, Davor Copic and Chandramohan George, led by Dr Michael De Volder, has engineered a solution. The researchers have designed carbon nanotube (CNT) microstructures shaped like small cones, which are attached to a flexible current collector to create a battery. CNTs are minuscule filaments made of carbon which have many fascinating properties, including excellent electrical conductivity. The microcone design created by the IfM team features a narrow base, which isn’t subject to stress or cracking when the battery is bent, and a wide crown which contains electrochemically active nanoparticles, making the cones into electrodes and therefore work as a battery.

Tests showed that, from a performance point of view, CNT cone electrodes can actually outclass existing flexible electrodes in terms of flexibility. The applications of this ground-breaking product can be endless thanks to its thinness, flexibility and durability.

Principal Investigator, Dr Michael De Volder, said: “We are only starting to understand the opportunities offered by carefully structuring carbon nanotubes. This unexpected application is only the tip of the iceberg of the applications Carbon Nanotube structures can offer. We are now focusing our efforts on the development of methods to fabricate these complex structures in large volumes at low cost.”

This project appeared in an article in the journal ‘Advanced Materials’, where you can find more information about the research.

The NanoManufacturing team will continue to research ways to enhance their battery’s features. Future projects includes designing a morphing battery that can be stored in small empty spaces or gaps within a structure, for instance on satellites.

To learn more about the group’s current research visit: www.nanomanufacturing.eng.cam.ac.uk