Student product designs unveiled at Design Show

A diverse range of eleven innovative design projects were on display at the Institute for Manufacturing on June 6th to mark the end of a year-long project.

The Design Show is part of the Manufacturing Engineering Tripos (MET) course, a programme for 3rd and 4th-year engineering students who have successfully completed the first two years of an engineering degree.

The aim of the design project is to develop a ‘new product’ with real business potential. Each team must work together to identify a customer need, research the market, develop an original design concept and create a full business plan.

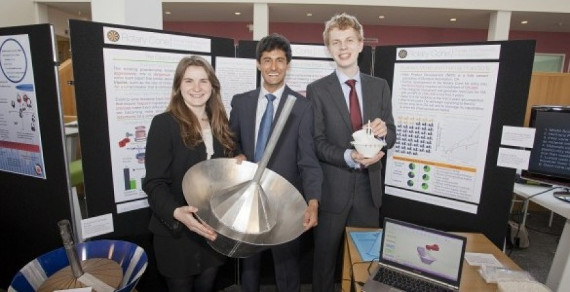

One of the products on display, the Rotary Cone has already been recognised by industry as a potential solution to a complicated and expensive problem. The Rotary Cone is a new approach for the removal of lumps for the food processing industry. With its simple cone-in-cone mechanism, it allows the rotating inner cone to crush and compress the lumps as they flow through, providing a safer, cheaper and more hygienic powder-lump prevention. The engineering students have been working closely with Peterborough based Olympus Automation, to provide a viable solution for this problem. A prototype is currently being manufactured for trial at the plant with the view to incorporating the Rotary Cone into their food processing chain.

Harry Norman, Managing Director of Olympus Automation said, “As part of Olympus Automation's commitment to working positively with the local community we were delighted to be approached by Pippa Horton, Arron Rodrigues and Robin Šmíd. Olympus Automation discussed various projects and together we decided to collaborate on powder-lump prevention as it presented a real challenge to the industry. Existing technology used aggressive, dangerous equipment that required extensive guarding with little flexibility to change minimum lump size. The Cambridge team created and developed a novel solution to the problem; Olympus Automation believe that this can be refined and taken forward into commercial applications. Throughout the process the Cambridge team have been professional, innovative & great ambassadors of the University”.

For more information on Olympus Automation’s R&D.

Another of the engineering teams have developed Medibox, a solution for the transportation and monitoring of temperature sensitive medical substances. Ed West and Elliot Dobson, two of the product designers explain the key benefits, “MediBox allows the safe, reliable and efficient transportation of temperature sensitive medical substances designed to solve real problems experienced in the field. A wide range of medical substances, including vaccines and blood samples, require careful temperature control during transportation and storage. In the case of vaccines, regulations state that they must be discarded if they fall outside a 2 to 8°C temperature window.”

Sidharth Khandelwal fellow team member, explains the key features, “With the Peltier elements and the in-situ thermometer, the temperature of the contents is precisely maintained and recorded, while warning systems alert the user to potential deviations”.

Another team of engineering students Karin Bergvall, John Gingerand and Lukas Wong have developed a hi-tech leg protection system for polo ponies, the Pegasus Polo Boot.

Karin explains, “Polo is a physically demanding game for both rider and pony alike. Unfortunately injuries to the ponies do occur but this product aims to reduce the risk of injuries, whilst also maintaining a comfortable environment for the ponies’ legs”.

Whilst current products on the market make use of bandage wraps combined with hard shell tendon boots, or neoprene wrap-around solutions, neither is optimised for performance or protection. The Pegasus Polo Boot uses a combination of hi-tech materials and technologies in order to provide superior impact resistance, cooling features, moisture control and ease of cleaning. Novel technologies such as hydrophobic coatings, phase change materials and high impact materials have been incorporated to bring the product into the modern age.

Other products on display at the Design Show were:

- Pulse - a headphone type device that enables deaf users to perceive sounds and their directions in unfamiliar environments.

- Unlayered – a revolutionary 3D printing technology that exploits submerged material consolidation for a rapid and novel manufacturing process.

- Hefti – a beekeeping aid to monitor the hive weight enhancing the chance of bee survival in the winter.

- Soteria – a device to protect motorcyclists from injuries caused by excessive head movement during collisions.

- Refleks – a solution to reduce the impact of potholes by forewarning motorists.

- Ectotherm – a device that enables skiers to vary the insulation properties of their jacket.

- WHB Acoustic C3 – high-end headphones that unfold to become a pair of portable speakers.

- The Ablus Equip – a device for manual wheelchairs to promote independence and improve safety on gradients.