Digital Manufacturing on a Shoestring update - Spring 2021

The Digital Manufacturing on a Shoestring programme is focused on the development of simple, low cost digital devices and systems that improve the effectiveness of operations of small manufacturing companies.

The Shoestring programme has now been running for two years and is beginning to produce an impressive set of outputs including:

- A prioritised “catalogue” of the most important digital solutions for small companies

- A simple step-by-step design procedure for producing a wide range of digital solutions (from low cost components)

- A set of “ready-to-go” solutions including:

- Digitising of legacy analogue display panels

- Digital job tracking system

- Shopfloor inventory tracking system

- Cloud based vibration monitoring

- 15 demonstrator systems and industrial pilots

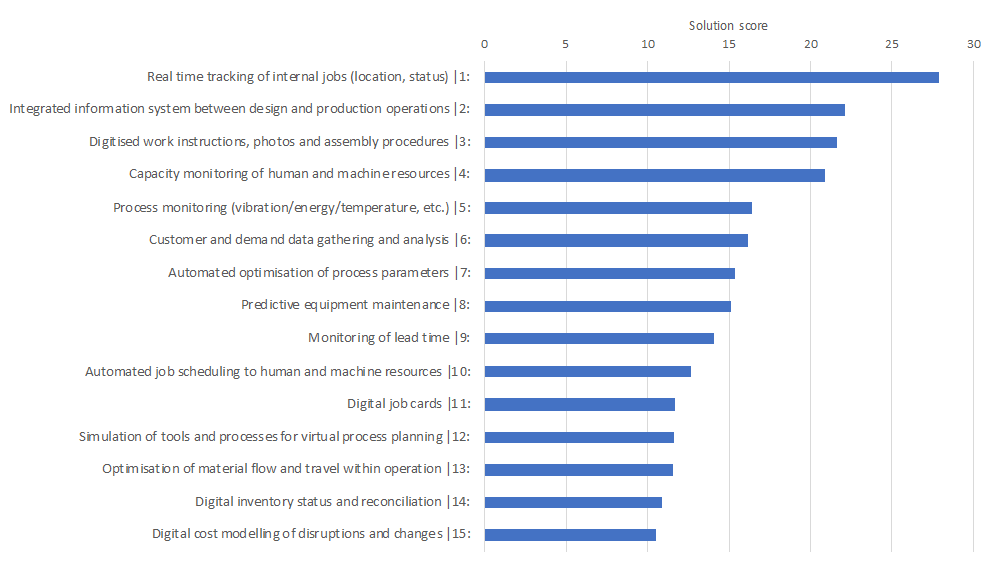

To ensure the industrial relevance of Shoestring developments and pilots, we conducted a requirements study to answer the question “What are the most common and important digitalisation needs of manufacturing SMEs”. The outcome was a reference set of typical operational challenges that SMEs face, that could be alleviated with a digital solution. The set, which we call a Catalogue of Digital Solution Areas, was created based on previous industrial case studies, and through workshops with over 100 small manufacturers at local manufacturing groups and industry summits.

The image below shows the top 15 priorities from the catalogue as indicated by the SME participants of the workshops. It is important to note that none of the solution areas identified in the catalogue are new, in fact technical solutions are available for all these problem areas. However, 86% of companies chose one of the top 5 solution areas as a highest priority for their business, showing that there is still need for an improved offering. The clear ranking enables the Shoestring project to prioritise low-cost solutions focussed on the most relevant problems of the majority of SMEs. The learnings from these solutions can then be applied to the solution areas from the wider catalogue, ensuring as broad an impact as possible.

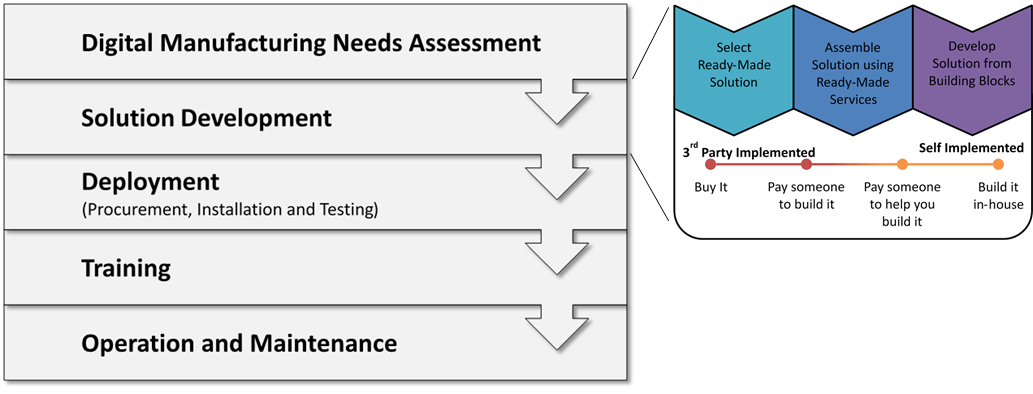

The shoestring approach provides a simple, structured pathway for small and medium sized companies to engage with digital manufacturing. It starts with a needs assessment that helps companies identify a good “next step” for them. This “next step” needs assessment can help companies that are new to digitalisation overcome the decision paralysis that often arises when “not wanting to make the wrong choice” comes into contact with the myriad of possibilities in the digital space, especially when they do not have the time to investigate these options fully. The needs assessment can be similarly beneficial to companies that are further along their digital journey, by helping them identify additional opportunities and prioritise their efforts.

The next phase in the approach is solution development. In this phase the “next step” solution identified in the needs assessment is designed using a three tier modular hierarchy, where solutions are assembled from solution modules which are in turn built from building blocks. To provide a balance between simplicity and customisation, an end user can stop at which ever rung of the hierarchy they are most comfortable with; they can select a ready-made solution, or they can develop something that meets their specific needs using service modules, or even building blocks. To simplify designing customised solutions, we use a template based approach that aims to reduce the knowledge required. Furthermore, a framework is being developed to integrate 3rd party support such as consultants or service providers for companies that do not want to embark on this development process alone. Once the solution is designed, it is deployed, the users are trained and it goes into day-to-day operation. We are currently engaged in a number of pilot deployments that are helping us identifies the best ways to structure this process.

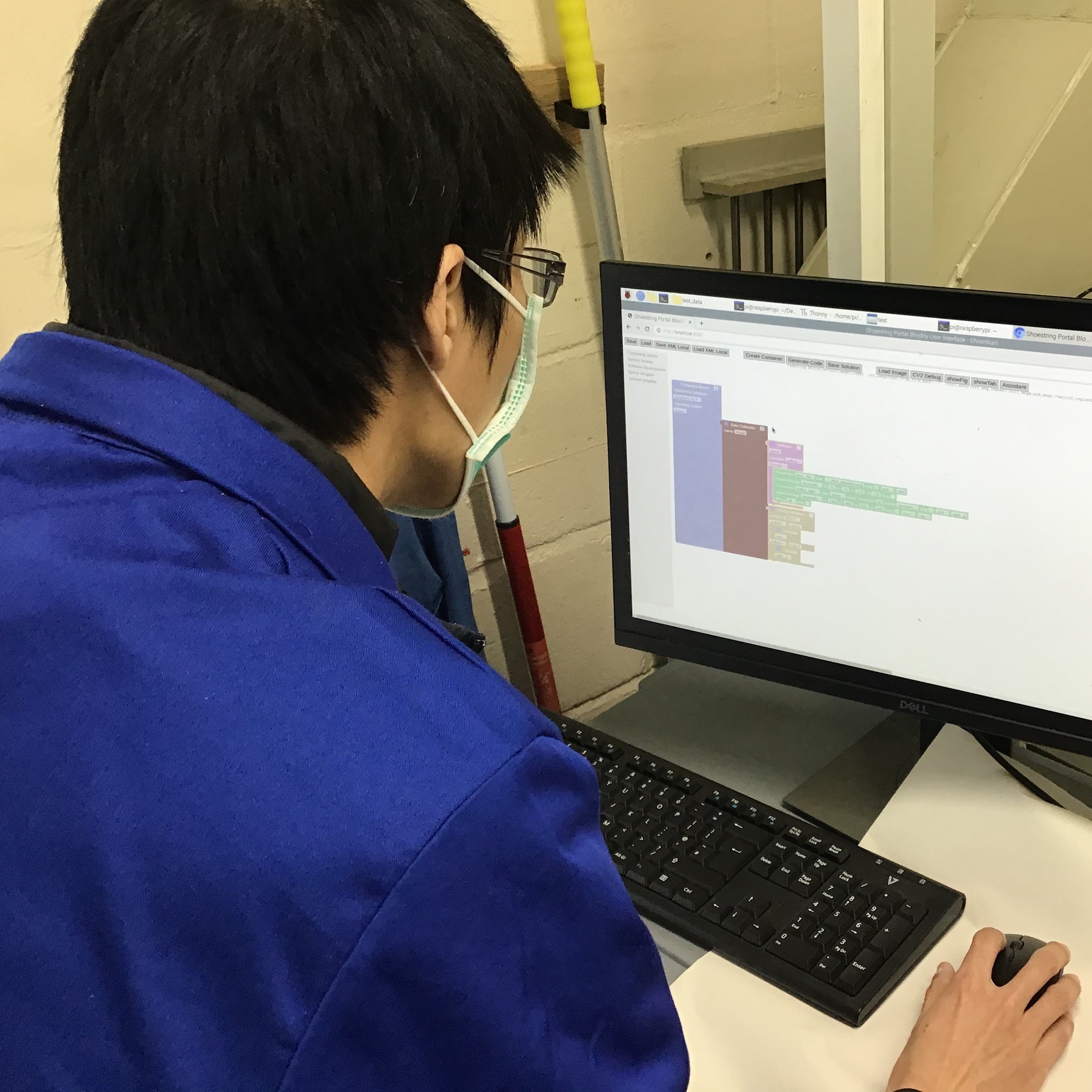

The Shoestring design portal is a web-based tool that allows end-users to either browse and adopt predefined low-cost digital manufacturing solutions, or visually design and ‘generate’ them from scratch—without doing any programming—by simply putting together existing technology 'building blocks' (i.e., hardware and software components ‘wrapped’ within suitable interfaces). The aim is for the design portal to be accessible to any manufacturing SME in the UK, to provide engineers, system integrators and solution developers from these companies with all the necessary information they need to develop and deploy their own digital solutions for their business needs using off-the-self, low-cost components and open source software. The design portal will ultimately also provide information guidelines and reference architectures that would allow subsequent digital solutions to be easily integrable with existing ones. This tool is part of a larger Shoestring portal development effort that will allow researchers, academics, regional associations, and technology providers to interact with SMEs, identify emerging needs and continue developing digital solutions and relevant technologies suitable for small businesses.

There are already a number of lab demonstrators and industrial pilots that have been developed as part of the Shoestring project. These have all been designed as solutions to the high priority needs that were identified from the various workshops; both at a one-to-many requirements level and a one-to-one specification level.

An example of one of the pilots is extracting, digitising and displaying data in real time from a legacy panel within the factory of one of the Shoestring Partners, as shown in the image below. The solution, whose hardware consists of a camera and a Raspberry Pi computer, is capable of recording and plotting the displayed temperature, the position of a switch and whether a light is on or off resulting in improvements to fault detection and quality control.

Another pilot underway is to do with Job Tracking. The Partner company now has easy and reliable access to the status and location of their jobs in progress which cost them a low 3 figure sum. This has resulted in reduced non-value added time looking for information as well as improved planning and decision making. In addition to seeing significant benefits from this solution they are also asking themselves ‘what else can we do?’ as the perceived barriers of digitalisation as being expensive and complex have, as a result of Shoestring, been removed.

In the next year the programme plans to develop a foundation that will support these solutions into the future and provide training and skills development for SME participants.

Meanwhile Shoestring “spin offs” in other domains are evolving. Programmes in construction, logistics and medical devices are underway, and various Shoestring-like initiatives for large companies have begun.

For more information see www.digitalshoestring.net and a recent webinar at: https://www.youtube.com/watch?v=Vro9AYpMmPg.

Date published

27 April 2021

For further information please contact:

Duncan McFarlane