MET Design Show 2025

The 2025 Manufacturing Engineering Tripos (MET) Design Show once again showcased an impressive array of creative and innovative student inventions. Over the last year, teams of third-year MET students have completed a major design project to develop a new product with real business potential.

Having first identified a customer need, the students researched the market, developed original design concepts, and created a comprehensive business plan. The projects have generated some exciting new ideas and innovative technology.

These designs are showcased at the IfM yearly MET Design Show. In the morning, students present their designs to an audience of IfM colleagues. In the afternoon, their designs are on display for faculty, researchers and staff to view and discuss the products with their designers.

Below are the exciting new ideas and innovative technologies that were generated for this year’s projects:

KETL

KETL’s Brewcycle gives tea bags a second life, separating plastic, reclaiming grounds, and turning tea waste into taste through compost-ready or BBQ-flavoured ORBs. Circular waste management made practical.

Tea is one of the most consumed beverages worldwide, with over 100 million cups of tea drank daily in the UK alone. While perceived as a natural product, the packaging tells a different story. Commercially available tea bags contain plastics and bioplastics that do not fully biodegrade. Current disposal practices treat the bags and grounds as one single waste stream, yet the grounds represent a valuable and underutilised waste product.

KETL is our sustainable solution. As a compact waste stream organiser, it separates the natural tea grounds from the artificial bag material, making disposal cleaner and more environmentally responsible. The teabags are processed through our proprietary BrewCycle which shreds the bag then sifts and compresses the grounds into ORBs (organic reuse blocks). Our ORBs serve two primary functions: composting enhancers and aromatic smoking briquettes. The nitrogen-rich compressed discs can be placed directly into soil to enrich plant growth and increase moisture retention. By adding our “Seed Infusion Packs”, users can transform ORBs into an easy-to-plant unit.

Alternatively, when infused with selected wood sawdusts such as applewood, oak, or hickory, ORBs become sustainable, flavour enhancing alternatives to traditional smoking woods. KETL transforms something once thrown away into a premium product for gardeners and barbecuers alike.

KETL is ideal for office buildings, hospitality venues, and commercial spaces seeking to reduce their environmental footprint through simple, effective waste management. By turning a common daily byproduct into a purposeful material, KETL contributes to a more circular and sustainable future.

Team: Aashi Bharat, Iona Haining, Ansh Jaiswal, Adubea Larson-Amartefio

ReFlo

ReFlo is an automatic sewing machine with ESG potential designed to allow customers to repurpose their garments into menstrual pads by simply taking them to their local shops.

Before the consumerist boom, periods were always addressed using reusable pads, though often under the form of a cloth tied at the hips. This was often uncomfortable and inconvenient to use, and thus capitalism answered the cry of society by inventing disposable single use pads. People around the world could easily discard their blood-soaked pads and adored the lack of maintenance.

Soon, the cracks began to form: disposable pads are expensive, they are dangerous to the body with prolonged contact, and create immense plastic waste. However, these problems were never big enough to trump the biggest advantage of all: convenience. In face of this, we asked ourselves a simple question: was there a way to deliver an improved reusable pad with the same convenience as the ones you bought at the supermarket?

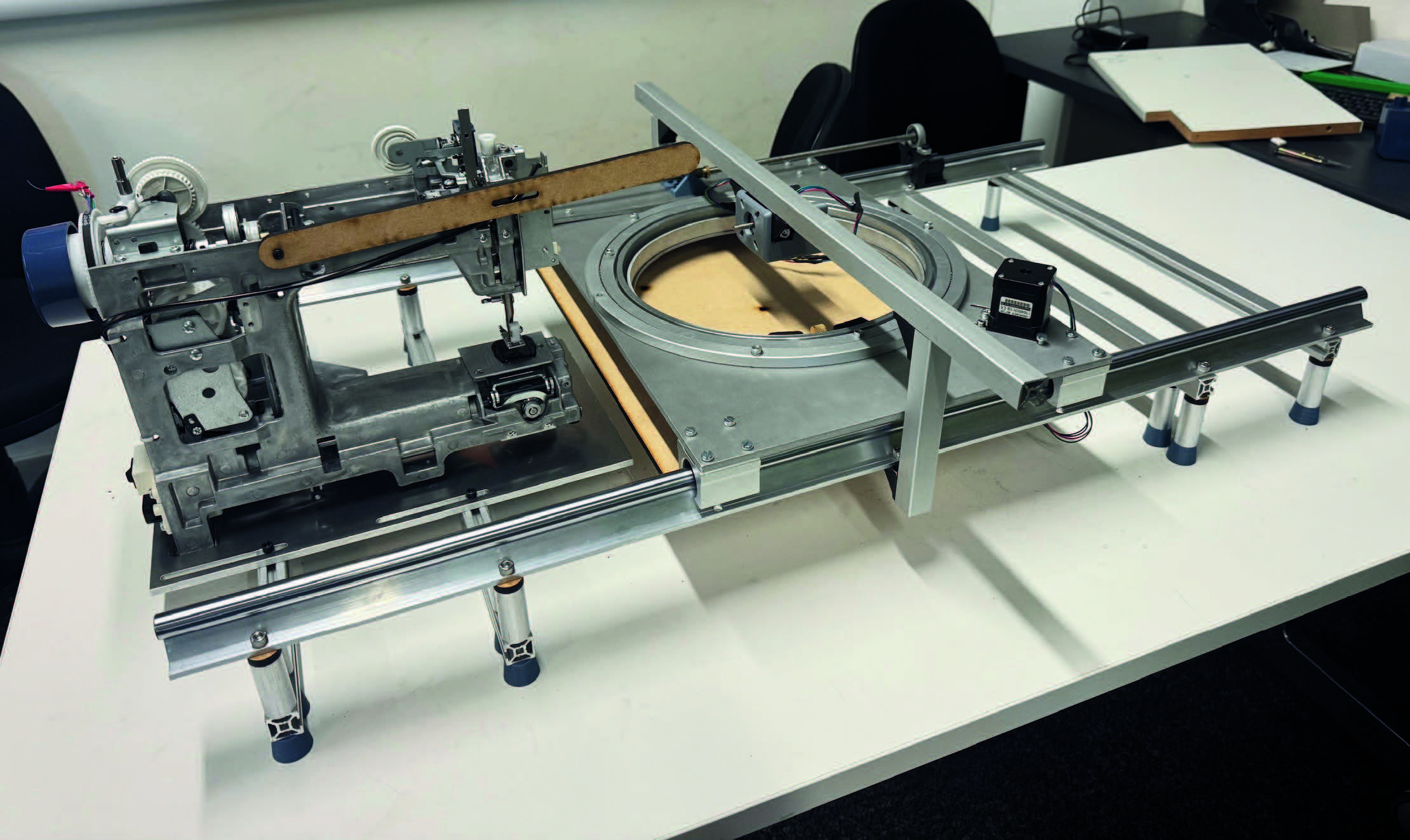

This is where ReFlo comes in: a machine that automatically makes reusable pads located at consumer’s local malls, allowing people with no sewing skills to make their own pads. Due to the pad’s standard shape, the pad could be accurately sewn with the help of an Xgantry, rotational fixturing hoop, and a conventional sewing machine. We wanted to make reusable pads as easy as pressing a button, literally.

After a few minutes of sewing, the machine produces a pad with the consumer’s desired fabric in time to accompany their weekly shop. The pads are designed to last 2 years before needing to be replaced, which removes the stress of wondering whether you still had a few pads left from that old pack in the back of your cupboard.

Overall, it is often the little things that truly make a difference. At ReFlo, we aim to deliver accessibility and sustainability through our products to make the lives of our customers just that little bit easier.

Team: Seyi Adeyemo, Juliette Rudelle, Lucas Wolman

MyTurn

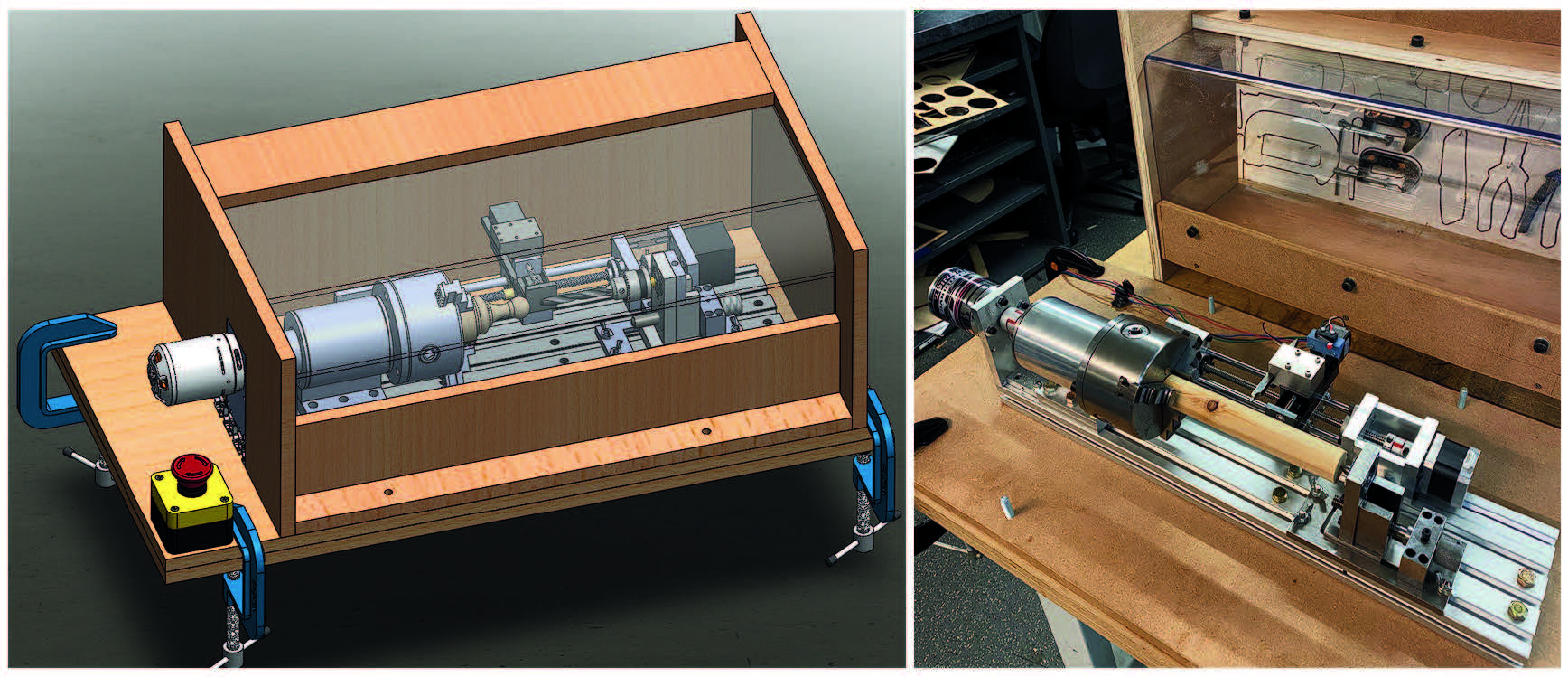

MyTurn is a small-scale, low-cost CNC lathe, providing hobbyists, schools, and small businesses with accessible, automated woodturning capability at a fraction of the cost of currently available CNC machines.

At present, there is a large gap in the lathe market. Manually operated wood-lathes sell for £50-1000, depending on size and power. On the other hand, even low-end CNC lathes are typically priced at or above £4,000. MyTurn bridges this gap – allowing safe, automated, high-precision turning of wood, wax, foam, or even chocolate – at a retail price an order of magnitude lower.

Armed with a wide-mouth chuck and capable of turning at speeds of up to 3000 RPM, our MyTurn prototype can handle stock up to 70mm in diameter and 200mm in length – and the final product range will include an option for a working length up to twice this.

MyTurn is highly accessible, even for those with no CNC or turning experience. The user simply uploads the desired profile via USB, loads the stock, and in just a few minutes, the workpiece is completed. A robust guard featuring a high-impact polycarbonate window ensures user safety and limits sawdust dispersion.

We see several viable markets for this product. The first is the hobbyist, for whom hand tools are often too imprecise (particularly if the piece is to be used in a larger assembly), and handwheel-controlled production is laborious (and impractical for curves). The second is the educational market. MyTurn will give secondary school students hands-on experience with (Computer Aided

Manufacture) CAM and CNC machining, crucial skills for future engineers in an increasingly automated world.

The third is small businesses. Whether it be chess pieces, table legs, ornaments or fancy chocolates, there are sure to be many thousands of small shops and businesses for which the ability to produce consistent axisymmetric pieces – without investing thousands on a full-scale machine, and with minimal labour – would be highly valuable.

Team: Harry Frith, Oscar Newall, Matt Newell, Meherwaan Sayyed

TheASM

A new way to cut foam, a simple way to make models.

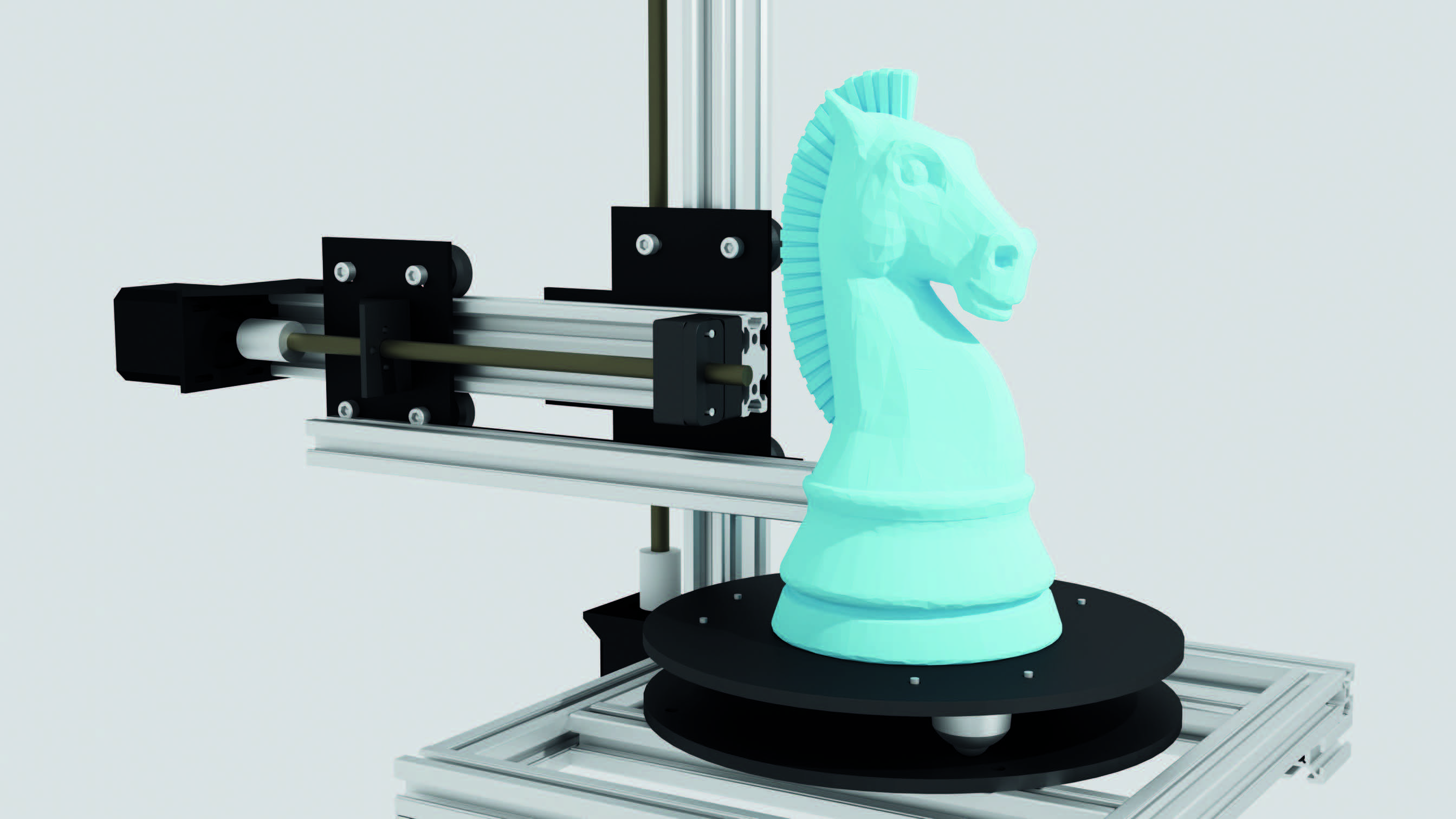

TheASM (Automatic Sculpture Maker) introduces a novel method of computer-aided manufacturing, innovating on the hot wire cutters commonly used to craft foam models. In contrast to the traditional linear cutter, a hot wire loop is mounted on vertical and horizontal actuators, reaching into a rotating block of foam, and enabling small sections of material to be removed. Computer numerical control is used to direct the motion of the actuators and position of the cuts, with material removed in layers; there is compatibility with standard computer-aided design applications as well as the potential to steer the cutter manually. More intricate

sculptures can be created due to the additional flexibility and resolution in foam removal.

The machine is designed to be a cheaper, more accessible form of computer-aided manufacturing compared to milling and turning machines and 3D printers. It will be accessible for all - hobbyist and business customers. There is potential for it to have a significant impact in education, teaching manufacturing principles in schools that cannot access more expensive equipment. The other incredibly exciting market that we are targeting is the theatre industry. TheASM machines can be used backstage to quickly and conveniently produce custom props and scenery, allowing faster implementation, greater flexibility and reduced costs. We hope this will be especially beneficial for supporting local theatres, in the growing challenge of staging economically viable and high-quality productions.

Team: Sean Huang, Daniel Kim, Aditya Tatwawadi, Sam Walker

medi[dr]op

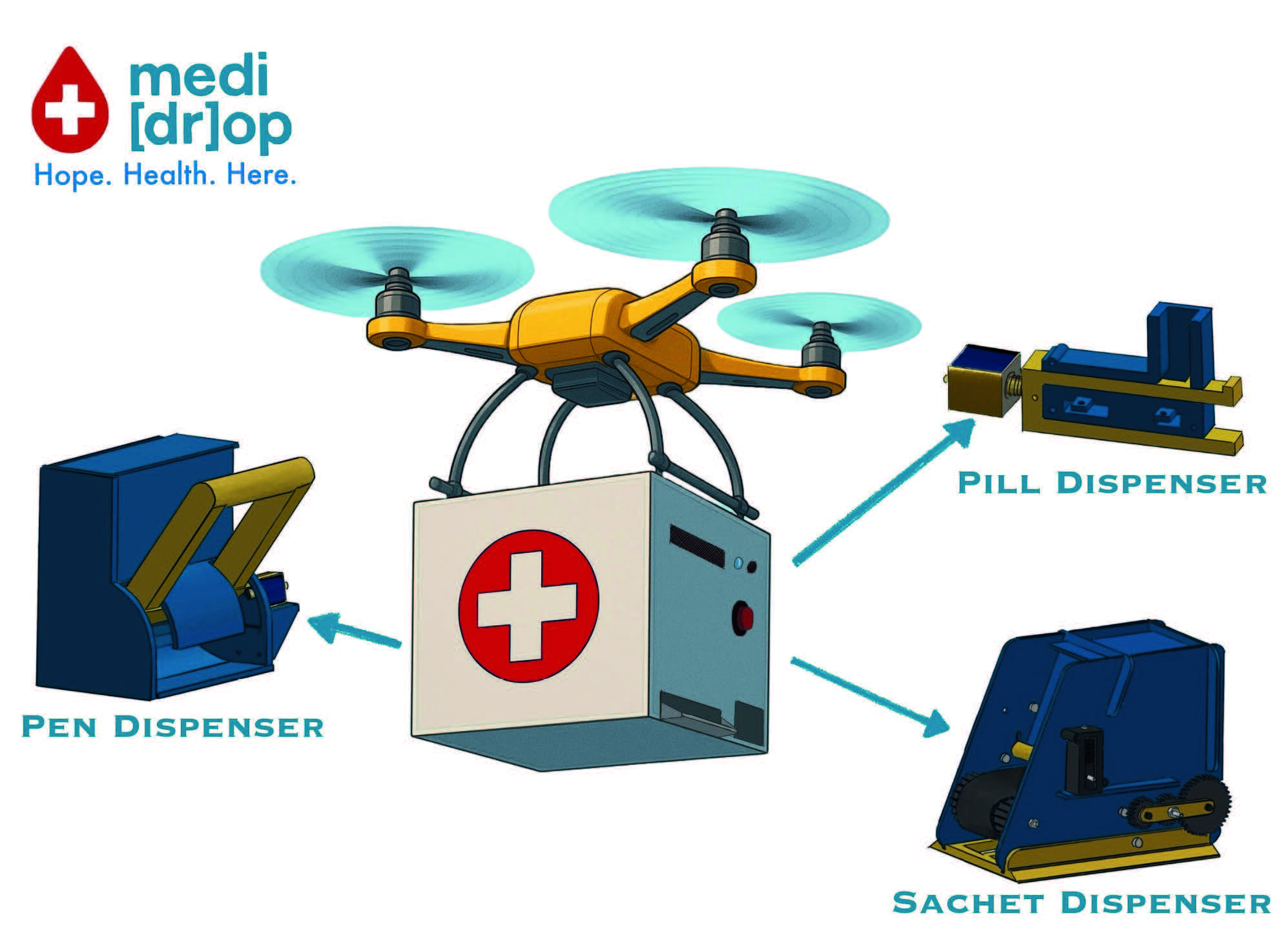

medi[dr]op is a rapidly deployable medicine dispensing machine designed for disaster zones, offering remote doctor connectivity for real-time prescriptions, secure dispensing, and quick access to expert medical advice in emergencies.

How It Works: Deployment begins with drones delivering medi[dr]op units directly to target locations - whether in disaster-struck urban zones or isolated rural environments. Once on the ground, the unit is activated by pressing a prominent red assistance button. This instantly initiates a secure video link with a licensed remote doctor, who evaluates the patient’s condition and prescribes appropriate medication on the spot.

Following the consultation, the prescribed medicine is dispensed directly through one of three integrated mechanisms:

- A pen dispenser for auto-injectors such as EpiPens and Insulin Pens.

- A pill dispenser for solid oral medications.

- A sachet dispenser for powders or rehydration solutions.

After receiving their medication, users also collect a printed receipt containing dosage instructions, expiry dates, and consultation references. This ensures clarity, traceability, and facilitates follow-up treatment if necessary.

Design Features: medi[dr]op features a modular sliding attachment system, allowing healthcare providers to customise the unit based on regional medical needs or anticipated scenarios. Modules can be interchanged or added -- for example, including additional storage for vaccines or temperature-sensitive drugs, or incorporating solar panels for extended autonomous operation.

The rugged design is engineered for quick deployment, ease of use, and resilience in extreme environments. Its intuitive interface, visual cues, and colour-coded components make it accessible for users with minimal literacy or technological experience.

Team: Changyue Liang, Qi Shean Lim, Harvey Nash, Jude Rothwell

ReJuice

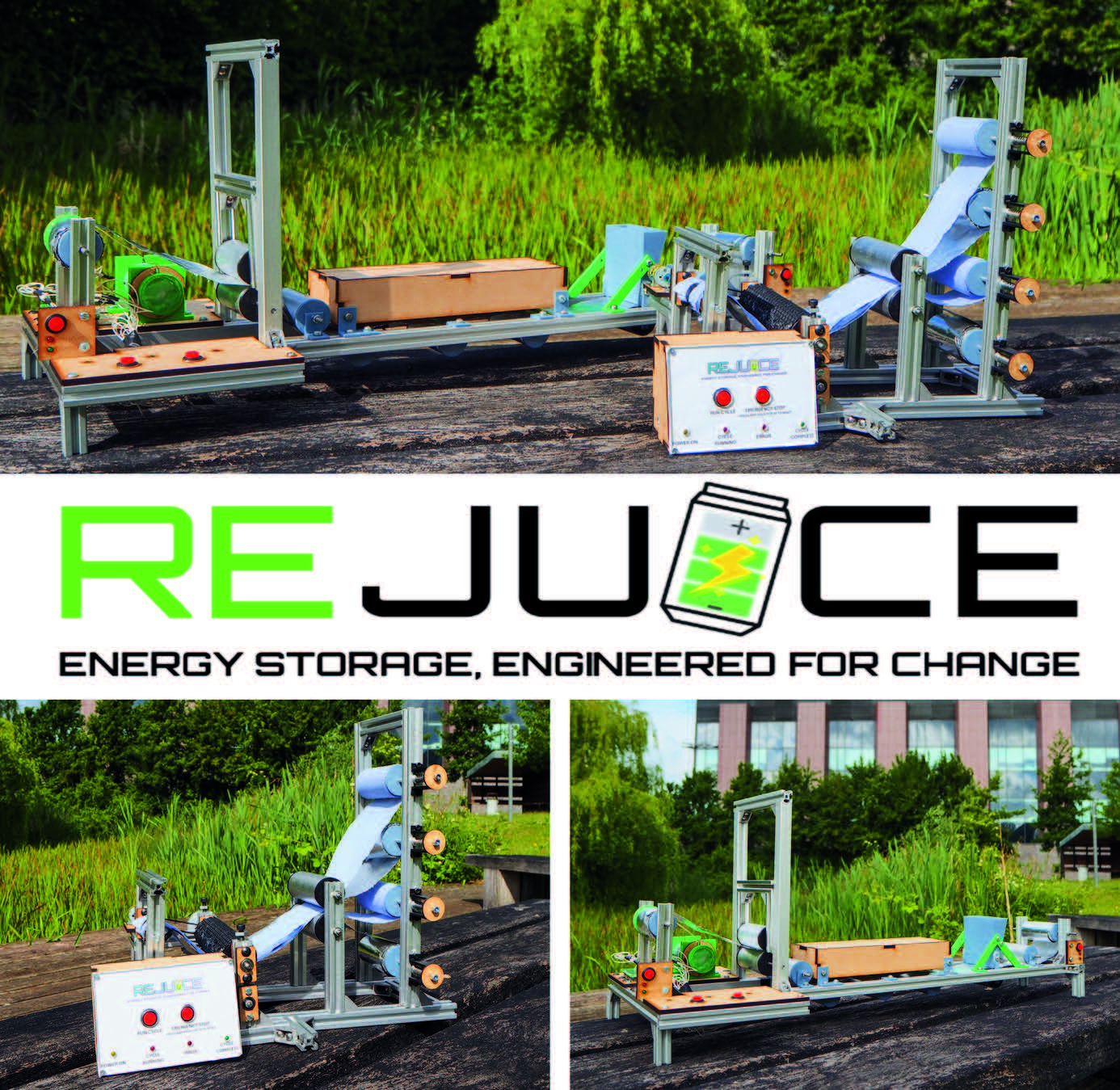

ReJuice is tackling energy poverty in sub-Saharan Africa, by providing machines for locals to make batteries in old drinks cans.

According to the International Energy Agency, 43% of the population of Africa currently lacks access to electricity. In rural areas, minigrids that utilise solar power are promising solutions; however, without affordable and safe batteries, communities are still unable to reliably access energy all day long.

ReJuice offers a simple and scalable answer: locally made batteries in recycled aluminium drinks cans.

ReJuice provides these communities with two simple-to-operate machines, which are used together to create zinc-ion batteries that can be housed within recycled drinks cans. With the help of these machines, and simple instructions, local people can make their own

batteries.

The first ReJuice machine prepares the materials, taking steel foil and adding a layer of ‘active ingredient’, which creates the cathode of the battery. This material can then be fed into the second machine, which uses rolls of zinc foil and a non-conductive separator to

create a cylindrical battery ‘core’ – the part of the battery that stores the energy. This core can then simply be inserted into a can. Finally, connections are made to this core using parts provided by ReJuice, creating a simple and effective battery.

Unlike lithium-ion batteries, zinc-ion batteries are not flammable and are far safer for use in high temperature environments. Furthermore, zinc is an abundant and low-cost material, often locally available in African countries, unlike the materials needed for lithium-ion batteries, which also raise significant ethical and geopolitical concerns. The lower energy density, but more stable charge/discharge cycles of zinc-ion batteries makes them ideally suited to stationary energy storage, such as in rural communities. Housing the batteries in recycled drinks cans creates a modular energy storage system, making ReJuice batteries small and easy to handle, whilst also reducing the number of aluminium cans going to waste. With ReJuice, communities can create their own clean energy future – one can at a time.

Team: Matthew Duxbury, Ben Munton, Philip Odugbile, Cian Phillips

METea

METea is your in-house tea alchemist—custom blends, curated powders, and fresh teabags on demand. From desk to detox, wellness just got wonderfully steeped in style. One machine, endless infusions.

Meet METea: the modern ritual for tea lovers with taste and standards. Designed for refined spaces—shared offices, serene spas, boutique producers—our compact machine blends ancient wellness with modern tech, and makes your tea as personal as your playlist. Here’s how it works: choose your preferred blend from up to 16 powdered botanical ingredients (green tea? ginger? lavender? maca? Yes, please). The machine delicately dispenses and blends your custom selection, delivers it into a biodegradable tea bag sheet, seals it, and—voilà—your perfectly portioned tea bag is ready to steep. You’re one button away from “ahh.”

METea is more than a machine—it’s a mini tea atelier, designed with soft curves and an earthy pastel palette reminiscent of SMEG elegance, but made for modern wellness. Think high design meets high function. Whether you’re boosting immunity, calming nerves, or just sipping mindfully, METea brews a better break.

We’ve also infused our offering with sustainability and smarts:

- Every machine comes with a seasonal subscription box of curated powders and signature blends

- Minimal mess, maximum flavour

- Built with high-quality, durable materials and a modular design for easy maintenance and scalability

For wellness spaces, it’s a guest delight. For offices, it’s a productivity perk. For tea entrepreneurs, it’s a game-changer. No more kettle queues or dusty boxes. Just botanical bliss, bagged with precision. Because life is too short for bad tea—and you deserve a blend that knows you.

Team: Amelia Beddy, Henry Broome, Benedetta Radice Fossati, Dini Witharana