Industrial Internet of Things: what is it, exactly?

Recently, I was visiting a major national automation institute (in another country) and asked the person in charge of the IoT demonstration facility what she considered Industrial IoT to be. In a wave of hands, the answer was: ‘Everything digital that can be used industrially’. I didn't feel especially enlightened, and used the opportunity when preparing a recent report and webinar to try and provide a simple introduction to IoT and its industrial application.

For me, the internet of things began as a means of extending the internet's reach from computers and devices to everyday machines and objects.

Hence the following Wikipedia definition is reasonable:

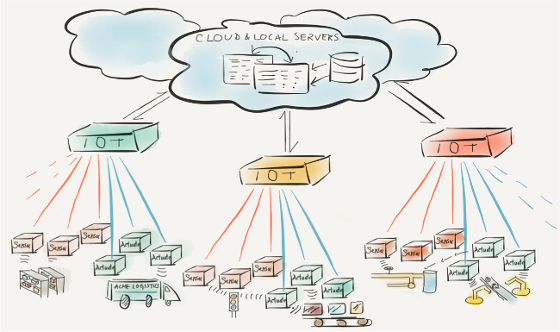

‘The Internet of things (IoT) is a network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, actuators, and network connectivity which enable these objects to connect and exchange data.’

(Wikipedia, 2018)

In essence, an Internet of Things is an enabling infrastructure providing a means for connecting objects to other objects, machines or people using an extension of the internet. It is therefore not a new network, nor a new technology or service.

If we now think specifically of what IoT means in an industrial context, the following definition (homegrown) at least is simple:

Industrial IoT is the application of Internet of Things developments to (create value for) industrial processes, supply chains, products and services.

Ignoring this distinction for the moment, applications that report the deployment of Industrial IoT solutions typically cover one of the following themes:

- equipment monitoring – gas turbines and construction equipment, trains, trucks;

- maintenance - aircraft, wind turbines, elevators;

- quality control – beverages;

- energy management – manufacturing;

- productivity – logistics, machine tools, oilfield production;

- safety – rail transport.

Because most industrial operations have very good IT infrastructure already, areas where Industrial IoT might provide the best immediate impact are applications where additional data is needed such as in:

- Integrating data from suppliers, logistics providers, customers;

- Introducing data from new technology, peripherals, tools, equipment;

- Distributed production requiring addition of new data sources, locations, owners;

- Sensors on board raw materials, parts, products, orders passing through organisations.

Written by Professor Duncan McFarlane