Elastic Manufacturing Systems - DIAL Newsletter Autumn 2021

High flexibility, dynamic market demand, customisation, high-quality products, flexible batches and short product life cycles are among the key factors driving manufacturing firms towards the transition to a new generation of manufacturing systems. The COVID 19 pandemic has also emphasised that to keep pace with the future manufacturing industry’s needs, firms need to be capable of reacting to demand changes flexibly and rapidly.

The elastic manufacturing project is investigating the concept of ‘elastic manufacturing systems’, which can be seen as an ability of manufacturing systems to scale output quickly and cost-effectively by provisioning and de-provisioning resources in an autonomic manner.

Conceptualising elasticity in the context of manufacturing systems

In a manufacturing context, elasticity can be analysed from the perspective of individual products or a mix of products. The project team has been conducting a range of interviews with manufacturing firms to understand how they responded to changes in demand during the pandemic and how their output varied in terms of individual products and mix of products. The data has supported us in conceptualising what constitutes an “elastic behaviour”. Interviews with manufacturing firms have revealed a range of enablers that supported output elasticity during the pandemic.

Assessing elasticity of manufacturing systems and supply chains

Manufacturing firms may identify that they need to improve their elasticity level in order to remain competitive. To identify if more elasticity is needed, manufacturing firms should be capable of assessing their current elasticity level. We are developing metrics to support manufacturing firms in measuring their current levels of elasticity. The metrics include an assessment from a focal firm’s perspective and a supply chain’s perspective. Manufacturing firms might consider assessing, for example, the “stiffness of their systems” or how their systems withstand “deformation” when a load is applied (i.e. when demand changes). A manufacturing firm might also consider assessing the elasticity of their network or supply chain and identify the elasticity performance of each company in their supply chain. The metrics under development will be tested and validated with manufacturing firms concerning their applicability.

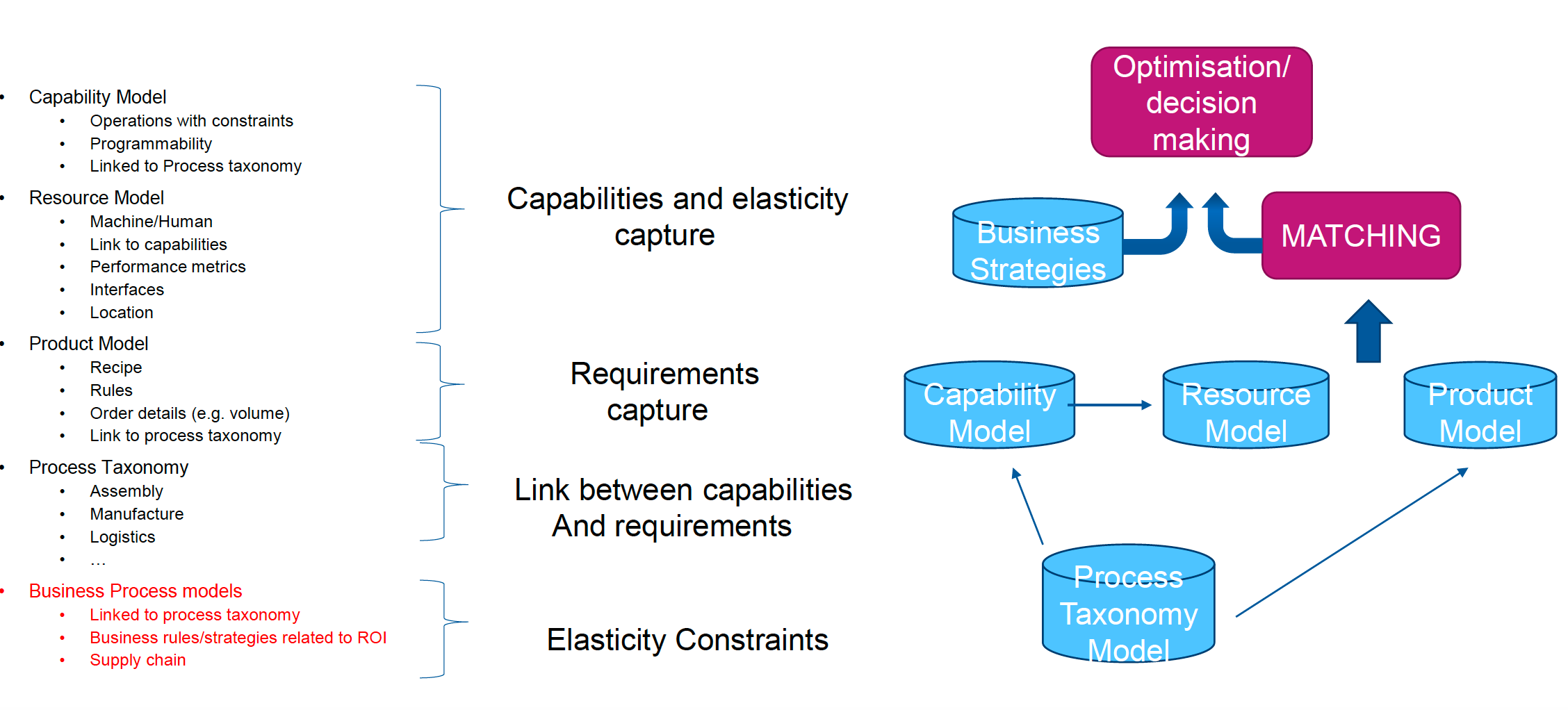

Semantic models

Insights from the interviews with manufacturing firms are also supporting the development of an elastic system morphology and semantic model. Data from the real manufacturing context has informed, for example, constraints that should be incorporated into the model.

For more information, please contact Thayla Zomer (ttdsz2@cam.ac.uk) or Sudhir Murthy (ssrr3@cam.ac.uk).

Date published

28 October 2021