DIAL raises the adoption of digital technologies through the Smart Manufacturing Data Hub project

The Distributed Information and Automation Laboratory (DIAL) was one of 11 partners to take part in the Smart Manufacturing Data Hub (SMDH) project, which ran from 1 April 2022 to 31 March 2025. Led by the University of Ulster, the Innovate UK funded project was designed to support small and medium-size manufacturers become more competitive by harnessing the power of data. Their goal was to increase productivity, raise the adoption of digital technologies, and get real value from available data, moving companies away from non-data gathering manual systems to informed production manufacturing systems.

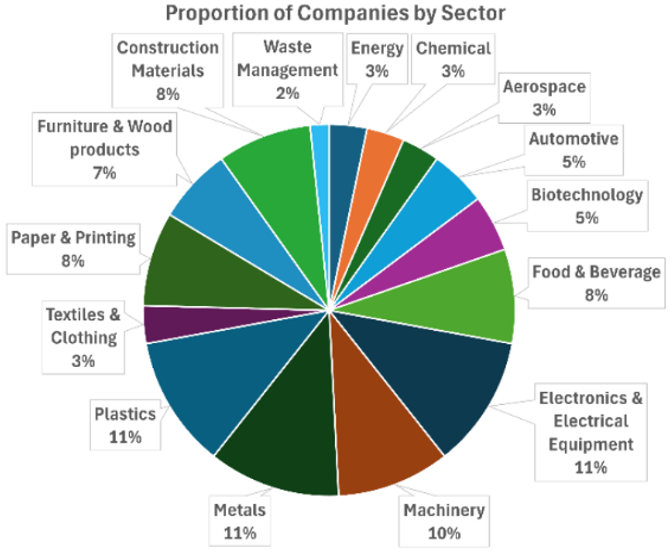

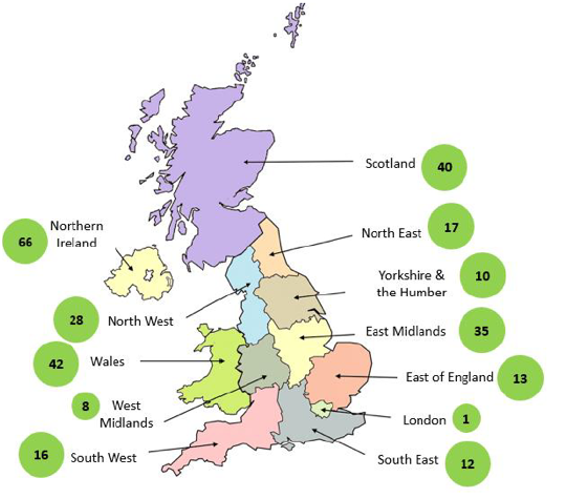

Over the 3 years, a team of researchers from the IfM, led by Dr. German Terrazas, engaged with more than 150 SMEs from across the UK. Their discussions resulted in over 100 adopting a total of 290 low-cost digital solution kits, all based on the Shoestring architecture previously developed at the IfM. The companies were distributed across 15 industrial sectors, including electronics and electrical equipment, machinery, metals and plastics manufacturers.

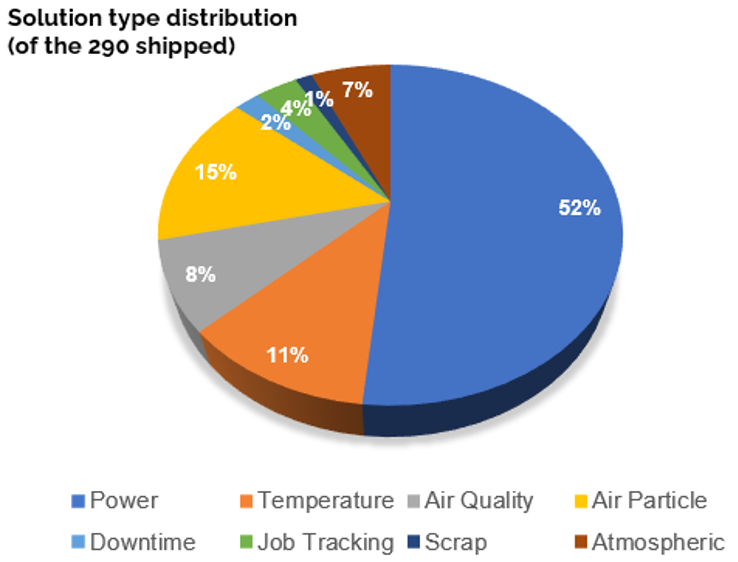

The digital solution kits were developed for monitoring current consumption, air quality, ambient/process/equipment temperature, atmospheric conditions, track jobs, quantify scrap and machine downtime. From these, power monitoring, air particle and temperature monitoring were the top three adopted solutions.

During the project, the team attended several in-person networking meetings and technology events attended by manufacturers, industry leaders and technology providers, including the Hastings 1066 group, Smart Manufacturing & Engineering Week, Smart Manufacturing Summit; NAAME Eoin Manufacturing Conference; GLEAM New Technologies for Food Manufacturing from Field to Fork; and the Northeast Manufacturing Expo.

Feedback received from companies was very positive, including the significant time and cost savings from the power monitoring and job tracking solutions and improvements to health and safety from air quality, air particle and temperature monitoring solutions.

Feedback highlights include:

- 90% considered the material and documentation provided suitable, as well as both the technical and the non-technical support from the IfM.

- 60% would continue to use their low-cost digital solution or extend the trial in their business.

- 75% would have liked to adopt more solutions.

- 50% identified they have developed new digital skills within their workforce.

Additionally, the SMEs have reported a significant improvement in their digitalisation, with most companies going from:

- collecting no data, to either semi-automated or automated data collection.

- storing no data to have data digitally accessible and available for relevant people.

- having no data visualisation and analysis to having dashboards with at least some analysis.

Furthermore, the majority of companies learned to understand their digital priorities, moved to a more comfortable position to acquire digital solutions or developed an ability to integrate digital solutions with business operations.

Although SMDH is now concluded, the Cambridge SMDH team - German Terrazas, Duvan Pineda, Ioan Webber and Liz Salter - continue to be involved with low-cost digital solutions at the IfM via the Shoestring Business Unit.

If you are interested in finding more about this project, the team would love to hear from you! Please email gt401@cam.ac.uk.