Dynamic and Adaptable Supply cHain Logistics (DASHLog) - DIAL Newsletter Winter 2020

Jorge Merino, Shuya Zhong, Vaggelis Giannikas, Alena Puchkova, Duncan McFarlane

DASHLog project started on June 2017 and ended recently on December 2019, and it was funded by YH Global Supply Chain Co., Ltd. DASHLog focused on improving warehousing and logistics operations, being the main objective to develop a system capable of detecting and understanding the operating environments and to switch on the most suitable mode to work with under the identified situation.

The main outcomes were optimisation methods and a system that supports operations environmental awareness and adaptability (i.e., switch to the most appropriate method) for enhanced and stable performance. This approach was tested in 2 scenarios: warehouse control (picking and packing) and replenishment scheduling. The results demonstrated an improvement in the performance of 18-23% and a cost reduction respectively, using the new methods.

Warehousing and logistics companies must operate every day in disruptive environments with fluctuating demand to respond and resources to manage. Thus, these organisations need to dynamically adapt to these operating environments to meet their customers’ expectations. Managers want to achieve a stable operational performance and increase it even when facing varying and challenging situations. Understanding how operations can work in different modes which are more suitable to these challenging situations is critical to ensure stable and enhanced performance, and to meet customer requirements.

Objective: To develop a system capable of detecting and understanding the operating environments and to switch on the most suitable mode to work with under the identified situation. The system is also capable of:

- Self-Adapting its behaviour to identified circumstances, providing guidelines to operations to adapt to new circumstances with minimum to no effort (stable performance), and identifying new unknown operating environments;

- Self-Evolving its modes to better respond to known and new operating environments.

Scenarios

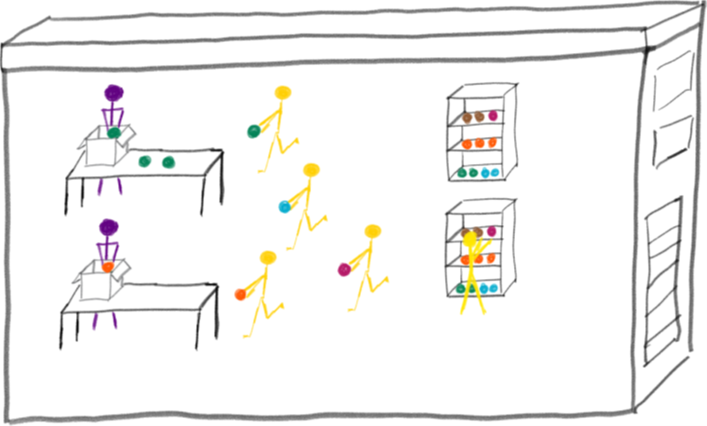

Intelligent Warehouse Control (iWC)

- B2C warehouse needs to fulfil large amounts of orders every day timely. How to generate picklists from orders is a core technique impacting the performance of picking and packing processes.

- Two brand-new methods developed (based on mathematical modelling and machine learning) to guide both order picking and packing processes.

- Evaluation Engine determines the most appropriate method to generate picklists in detected situation.

- KPIs (makespan, labour efficiency, average order processing time) are validated in pilot test to have 18-23% improvement by using the new methods.

- Application scenarios can be extended to B2B and automated warehouses etc. in the future.

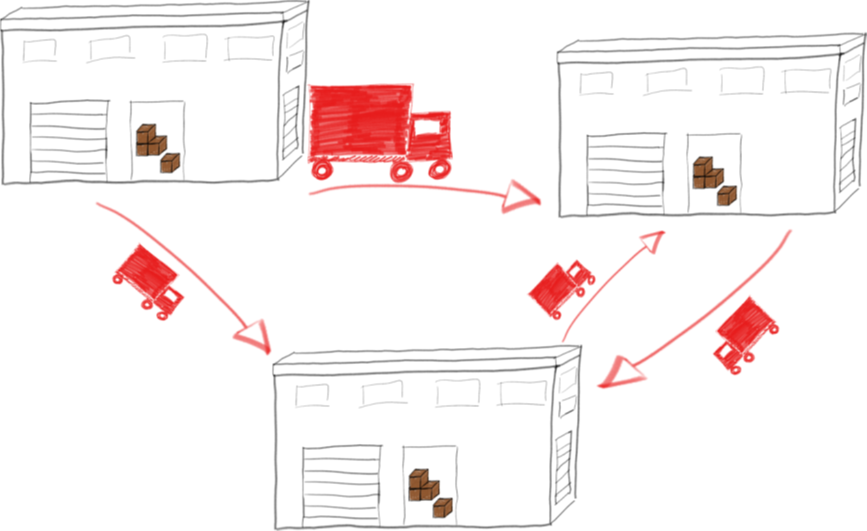

Intelligent Resources Scheduling (iReS)

- Inventory management and transportation decision making can be challenging in a distribution network that integrate supply, storage, and transportation activities. How to align inventory and transportation decisions could lead to substantial cost savings and improved service levels.

- A brand-new method developed (based on mathematical modelling) in order to support inventory and transportation decision making.

- New method helps to deliver products on time and meet customer demand minimising system-wide cost, without hurting product availability.

- iReS method has the potential to use the entire distribution network in a more efficient way, reduce operational costs and adapt to demand changes.

Date published

28 January 2020