IfM spin-out Matta raises $14M to transform how products are designed and manufactured

Matta, an industrial AI spin-out from the Institute for Manufacturing (IfM), has raised $14M in funding to transform how products are designed and manufactured.

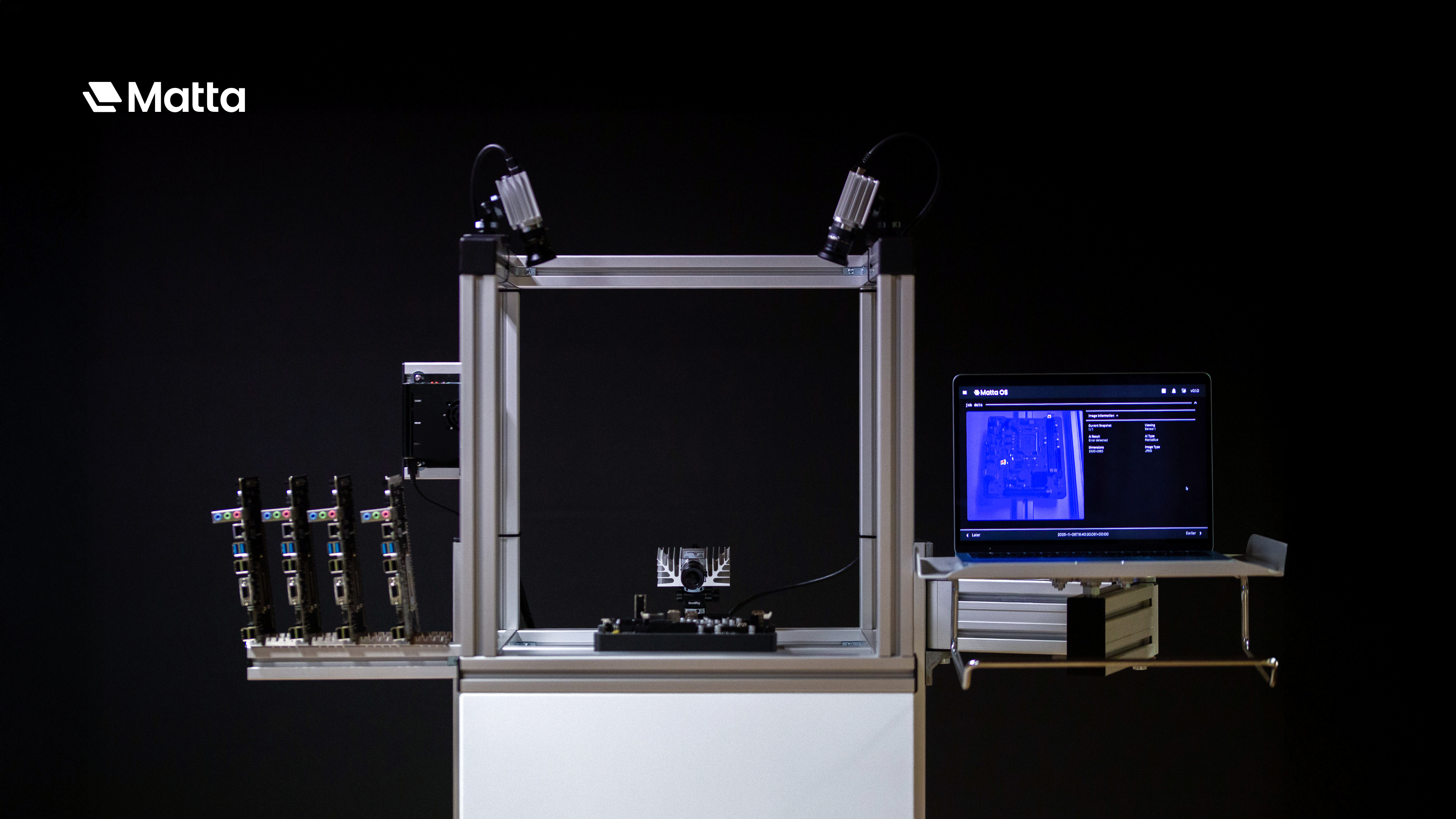

Matta’s AI gives factories the ability to see, understand, and improve themselves in real time, understanding any production line within days. It spots defects, traces root causes, and helps teams fix problems before they become costly.

The technology is highly adaptable, capable of working across everything from electronics and automotive to defence and apparel, whether on manual inspection stations, conveyor lines, or robot arms to redefine how products are conceived and created. This generalisation capability is driving strong demand, with 300+ factories in the pipeline and a new installation every two weeks.

Matta was founded on pioneering research from the IfM, where co-founders Douglas Brion, who completed a PhD in deep learning-enabled control, and Sebastian Pattinson, Associate Professor of Engineering and leader of the IfM's Computer-Aided Manufacturing group, first met.

The seed round was led by Lakestar alongside investors Giant Ventures - who led the pre-seed - RedSeed VC, InMotion Ventures, 1st Kind (Peugeot family), Unruly Capital, and Boost VC, with grant support from Innovate UK and the Royal Academy of Engineering.

Doug Brion, Co-founder and CEO of Matta, said: “Everything around us is manufactured, from the mug on your desk to the optical cables carrying our Netflix binges. Everyone talks about the glamorous side of manufacturing: generative design, material discovery, digital twins, but few spend time on the factory floor.

"The hard part isn’t dreaming things up inside a computer; it’s making them work at scale. Manufacturing still runs on human know-how, the kind that lets someone on the line kick a machine just right, or run a finger over a scratch, and say ‘that’s thirty-four microns wide.’ We’re using AI to capture and scale that tacit knowledge, so engineers can design things that actually work in the real world. It’s time to manufacture the impossible."

Manufacturing is at an inflection point

Manufacturing underpins a third of global economic output yet remains plagued by inefficiencies that waste up to 20 per cent of production value and raise emissions.

After decades of deindustrialisation, factories are exposed to external geopolitical shocks and must do more with less. Matta provides a practical route to productivity, quality and resilience on today’s shop floor.

At the same time, energy costs are rising, supply chains are fragile, and workforces are ageing. Factories must reshore, decarbonise, and do more with fewer skilled hands. In the UK, vacancies already outnumber qualified engineers, and costs continue to rise. Across Europe and the US, the story is the same.

Matta: building the first sentient factories

Matta develops AI that learns the physical rules of production and applies them on the line. Its first product uses unsupervised and self-supervised computer vision to automate quality control and anomaly detection, perform measurements, diagnose root causes, and recommend corrective actions in real time. A central platform lets teams monitor every camera, analyse results and trace parts across the factory for live visibility of issues and bottlenecks.

Matta delivers this as a full plug-and-play system combining hardware, factory integration, AI research, and software. Most deployments are live within hours, with cameras inspecting automatically after a short learning period. In one polymer manufacturing deployment, Matta achieved over 99% defect-detection accuracy with just ten minutes of data. Recent projects range from inspecting high-speed bottling for defects with a global drinks brand to working with Bowers & Wilkins, where Matta’s AI rapidly measures speaker components to catch issues before assembly.

Beyond detection, Matta partners with OEMs to enable machines to tune themselves. One of these OEMs, Caracol, is integrating Matta’s vision AI for closed-loop control, linking real-time inspection to automatic parameter adjustments on industrial printers and large-format robot additive manufacturing cells.

Led by world-class academic founders

Today, Matta is a fast-growing team with experience from MIT, Imperial, BBC R&D, Google X, and Microsoft. Akis Bratsos of Lakestar said: “We are thrilled to be supporting Doug, Sebastian and the Matta team as they go on to revolutionise manufacturing through the use of industrial AI. Their approach combines cutting-edge technology together with fast time to value that is rare in the sector.”

Madelene Larsson of Giant Ventures said: “Doug and the team have developed a transformative approach to rapidly training factory-ready AI with minimal data, which has the potential to reshape how products are made. We're excited to back the team as they sprint towards a future defined by autonomous manufacturing and inverse design."

The latest funding will accelerate customer adoption and AI development, expand self-serve deployment, and support Matta’s expansion into key manufacturing regions across Europe and the US, advancing the company’s vision for fully autonomous, end-to-end production.

About Matta

Matta is building industrial AI for factory sentience, enabling factories to sense, understand, and adapt in real time. Based on pioneering Cambridge research and driven by a team with experience from MIT, Google X, and Microsoft, Matta is replacing the traditional designengineer- build workflow with AI. By cutting waste, boosting productivity, and opening new frontiers in manufacturing, Matta is redefining the future of industrial innovation.

About Lakestar

Lakestar is one of the leading pan-European venture capital firms. Lakestar’s mission is to find, fund and grow disruptive businesses that are enabled by technology and founded by exceptional entrepreneurs in Europe and beyond. Founded by Klaus Hommels in 2012, Lakestar raised an aggregated volume of over USD 2.5bn across different products and funds. The team actively advises and supports portfolio companies in marketing, recruitment, technology, product development and regulatory insight, accompanying founders from seed to early stage, growth stage or exit. Lakestar currently has the privilege of holding investments in Revolut, Auterion, Fuse, Nelly, Blockchain, Public, Dexory, Exein, HomeToGo, IsarAerospace, Neko Health, sennder and Vertice, to name a few. A long-standing champion for Europe’s digital sovereignty, Lakestar has a presence in London, Berlin and Zurich.

About Giant

Giant Ventures backs purpose-driven founders solving the world’s biggest challenges. Giant Ventures was founded in 2019 by Cameron McLain and Tommy Stadlen, two exited technology entrepreneurs and investors. Giant invests in ambitious founders across Pre-Seed, Seed and Series B in Europe and the US, to create multi-billion dollar companies that drive global change.