£1 million EPSRC funding paves the way for advanced carbon nanotube processing

A team of researchers from the IfM's NanoManufacturing group, the University of Cambridge’s Department of Engineering, and University College London have been granted £1 million by the Engineering and Physical Sciences Research Council (EPSRC) to advance carbon nanotube processing.

The project is part of a larger £4 million investment by EPSRC into 'adventurous manufacturing,' aiming to foster highly transformative research that could disrupt the future of manufacturing.

The three-year project will explore how carbon nanotube structures can be effectively processed and integrated into scalable manufacturing processes. It brings together various aspects of carbon nanotube processing that have been developed at the IfM over the past ten years, building on the pioneering work by Professor Michael de Volder and PhD researchers Sammy Mahdi and Maxime Burgonse.

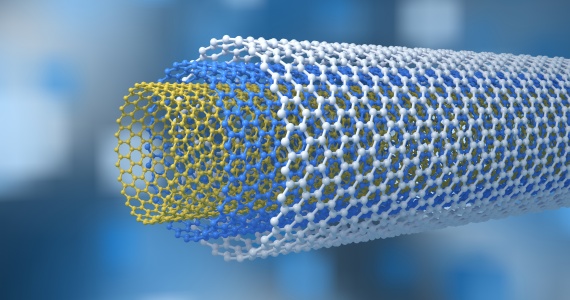

Carbon nanotubes

Carbon nanotubes (CNTs) have emerged as one of the most extensively researched and commercially promising nanoparticles to date. Their success is largely attributed to their exceptional physical properties, unmatched by any other engineering material.

However, the outstanding properties of individual CNTs are not directly applicable to most commercial applications, which require the assembly of tens to millions of carbon nanoparticles into a single device. To address this challenge, the development of novel manufacturing processes becomes imperative, allowing controlled assembly of CNTs and their integration into devices.

Professor Michael de Volder, lead of the IfM’s NanoManufacturing group, emphasises the complexity of manufacturing such devices reliably:

“Not only is there a need to overcome synthesis and assembly challenges of CNTs, but the delicate CNT structures also require interfacing with electrodes for electrical read-out and often need to interact with gases or liquids in various applications like sensing, microfluidics, biomedical, and energy storage.

“With the support of the EPSRC grant, we aim to demonstrate a ground-breaking multi-scale manufacturing approach. This innovative approach allows for individual optimisation of different device length scales, a strategy never attempted before.

“The resulting set of manufacturing techniques will serve as a versatile platform technology capable of solving diverse engineering problems and finding applications in chemical sensors, biomedical devices, microfluidics, and actuators.”

A key aspect of this project involves partnering with UK-based manufacturing companies to ensure that the developed processes are integrated into the UK industry, benefiting both academic and industrial stakeholders.

“The ultimate goal,” says Michael, “is to bring high-end products utilising CNTs closer to the market, paving the way for enhanced technological advancements and applications.”

Research group: Professor Michael de Volder (Institute for Manufacturing, Department of Engineering, University of Cambridge), Adam Boies (Energy, Fluids and Turbomachinery, Department of Engineering, University of Cambridge) and Buddha Deka Boruah (University College London).

Find out more about the IfM NanoManufacturing group here.