Manufacturing Device Platforms

Controlling the flow of very small volumes of liquid (and suspensions) along sub-millimetre scale channels or through porous materials is very useful already in an array of diagnostic technologies. Inexpensive and reliable lab-on-a-chip devices are key to improving both the global accessibility to rapid diagnostics and the detailed monitoring of responsiveness to treatment.

To achieve this for a broader range of applications and to ensure a clear pathway to manufacture, we are tackling simultaneously the challenges faced in delivering quantitative diagnostics and the manufacturability of the engineering solutions.

This work, described as "microfluidics", shares many similar principles to the underlying challenges in inkjet technologies and control of supramolecular gels, especially the need to understand the liquid surface tension and rheology as well as the role of the microfluidic channel micro- and nanostructures. The wide range of sample types (e.g. whole blood, plasma, urine, saliva) and the difference in fluid properties between people leads to a very clear need for repeatable and robust systems. Challenges are faced in ensuring the sample flows at the correct rate along the channels and interacts with the detection reagents to allow sufficient reactions to occur. Manufacturing these systems requires simple, traceable, techniques that can be translated to both a relevant scale and meet the appropriate manufacturing standards for medical devices.

Working closely with the Cambridge Analytical Biotechnology (CABs) Hall Laboratory, and following completion of the FP7-funded BiognostiX project our work focuses on:

-

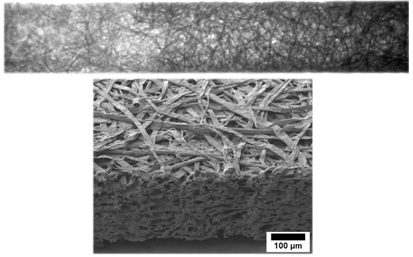

Fabrication of paper-based diagnostics where the capillary flow is along the channels in between the cellulose fibres. Paper is a sustainable, chemically robust, abundant material with well-understood manufacturing routes. It provides a naturally three-dimensional matrix upon which reactions can occur as well as an inherent ability to transport aqueous-based samples by surface tension forces.

-

Novel approaches to fabricating standard microfluidic channels to improve their ease of manufacture and late-stage customisation.

-

Incorporation of functional materials into microfluidics to enhance the ability to sense components to a high degree of selectivity and sensitivity.