Soft Matter Manufacturing Research

Developments in organic and synthetic chemistry have led to incredible discoveries in the manipulation and combination of molecules into complex macro-architectures. The design of polymers is an exciting field, producing an incredible range of chemical, biological, mechanical and electrical functionality in organic materials. The results can be seen in an array of everyday item such as clothing, display technologies or medical implants.

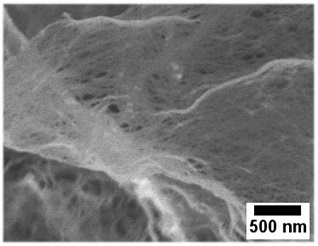

While polymers rely on strong covalent bonds to hold together the chains of molecules, supramolecular chemistry looks at the full spectrum of chemical bonds available. These other, usually weaker, bonds (e.g. π-π stacking, hydrogen bonds, van der Waals forces) can deliver more complex structures where both the chemical groups and their physical structure are designed to meet a certain task. For example, the two strands that make up DNA rely on very specific hydrogen bonding to give the famous double helical structure. Another example is the use of cage structures, built around 'guest' molecules or ions that then allow them to be transported through cell membranes for medicinal chemistry. We are examining both types of macromolecules and the challenges in controlling their hierarchical structure while maintaining their function.

One of the areas we are most interested in is tissue engineering applications and drug delivery devices. To create better in vitro techniques for testing new drugs and also to improve cell, tissue and organ replacement therapies, we want to replicate the natural conditions for cell growth and tissue formation. FIAM doctoral student, Qingxin Zhang, is looking at how liquid engineering can be used to build polymer microstructures containing materials such as small-molecule drugs. To tackle the manufacturing challenge, she is combining a self-assembly technique with a controllable digital patterning of liquid drops (by inkjet printing) on to liquid surfaces. These are then guided to selforganise into patterns that will eventually support cell growth and the slow release of drugs.

The incorporation of active or responsive materials into functional polymers and supramolecular structures along with the detailed geometrical control has led to identification of a very broad range of applications from photovoltaics and energy harvesting to regenerative medicine and medicinal chemistry. With a strong chemistry background and firm grounding in manufacturing considerations, we are working with the School of Chemistry in Trinity College Dublin (Supramolecular and Medicinal Chemistry Research Group). to understand in detail the influences of manufacturing on the delicate balance of chemical properties and their end function.

Our aims, specifically in projects on photovoltaics and regenerative medicine are to:

-

Tune the materials to enable delivery and patterning methods and validation of the resulting devices.

-

Pioneer the metrology of highly complex materials exposed to harsh manufacturing conditions.

-

Work with industrial collaborators to ensure the techniques are appropriate for implementation into the value chain.