Realising the new kilogram - A linear mechanism to for the next-generation Kibble balance

Background

The kilogram is currently defined by the mass of a material artefact: the International Prototype Kilogram (IPK). Comparisons between the IPK and its sister copies show tens of micrograms of divergence over the last of century. This implies the mass unit is unstable and so too, by extension, are the units, such as the watt, newton and volt, which derive from mass.

At the 25th meeting of the General Conference on Weights and Measures (CGPM) a resolution was adopted to revise the International System of Units (SI). In May 2019 the ampere, the kelvin, the mole and the kilogram will be redefined in terms of fundamental constants. The aim is to make the SI more coherent, to guarantee long-term stability and to facilitate wider end-user access to traceable measurements. [1]

After the redefinition of the kilogram, the National Metrology Institutes (NMIs) of the world will need experiments and instruments which realise mass with relation to the Planck constant with an uncertainty of better than 1 part in 108. Currently the cost to develop, maintain and run such instrumentation typically requires a large dedicated laboratory, a team of engineers and scientists, and a multi-million pound investment.

The National Physical Laboratory (NPL) is collaborating with other NMIs to develop the next-generation Kibble balance. [2-4] This will exploit a new operational mode to deliver the required high-precision in an instrument which is cost-effective (£100ks), easy to operate, and producible on a small commercial scale. It will enable the mass unit may to be realised not just at NPL for the UK, but by any NMI which purchases one.

The next-generation Kibble balance

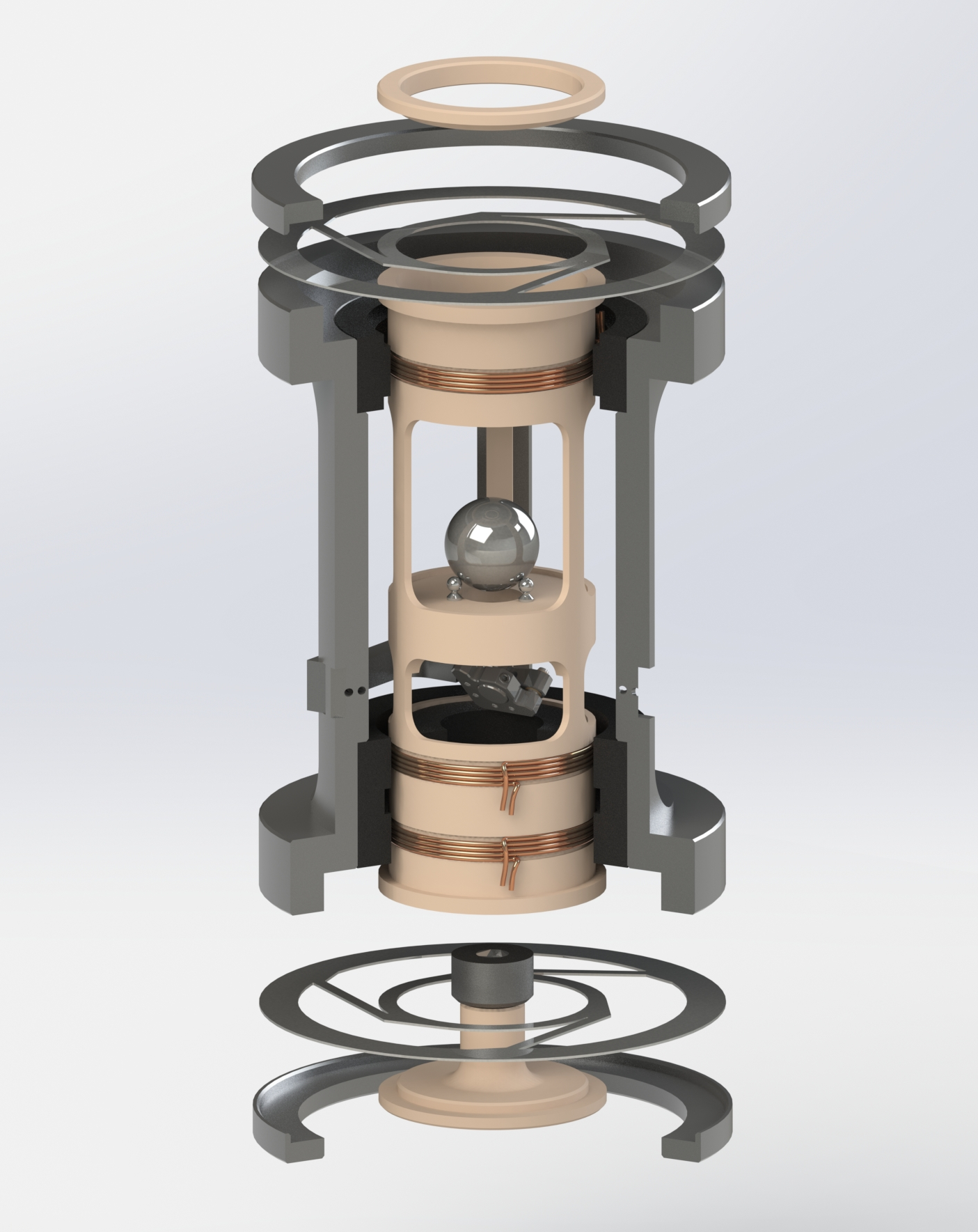

A Kibble balance is an electromagnetic mechanical system which links a mass (via weight) to electrical quantum standards and so to the Planck constant. The mass under measure must be supported against gravity and free to travel vertically by some linear guidance mechanism.

In 2014 Kibble proposed a new-type of Kibble balance. [2] The new design concept utilised the fact that if the linear guidance mechanism of the balance is rigid in all but the vertical axis, then misalignment errors are cancelled. This will enable the balance to be smaller, scalable, cheaper and more usable whilst maintaining precision.

Research objective & requirements

The principle focus of this research is to find or develop a methodology which enables a novel linear guidance mechanism for this instrument to be designed and optimised. This mechanism must allow the instrument to realise the required uncertainty levels and this performance must be experimentally validated.

Broadly speaking, the next-generation Kibble balance needs a linear guidance mechanism which meets the following requirements.

- High sensitivity when weighing (ie. low stiffness in the vertical 100 N/m)

- Large vertical range when calibrating (±10 mm)

- Sub-nanometric repeatability, predictability and precision

- Negligible static friction

- Minimal sensitivity to alignment errors

- Relatively low mass (0.1 kg), low out-gassing and low magnetic susceptibility

- Capable of supporting ±5 N and travelling at 10 mm/s

Although, as a complete Kibble system will likely cost in the order of £100k, there is not a significant constraint on the cost of the linear guidance system, manufacturability, lifetime and robustness are advantageous. Additionally, due to the active temperature control which is required for other components (principally the magnet), it is unlikely that the thermal sensitivity of the bearing will be a critical factor. Nevertheless, it would be desirable if the bearing itself does not produce significant heat.

Research approach

Research will be subdivided into some key stages.

- Technology selection

Potential applicable technologies for the linear-guidance mechanism need to be identified by a literature survey and the most suitable selected through qualitative comparison. - Geometry selection

Once a potential technology is selected, the best implementation of that technology needs to be found. This will be done by identifying suitable existing geometries from the literature, finding design methodologies from the literature, and by developing novel designs /design methodologies. These designs will be modelled and undergo a quantitative trade-off. Those that are the most promising will be selected for optimisation. - Design optimisation & validation

The first stage of design optimisation will be experimental model validation. Ultimately the complete mechanism will need to be modelled, but the process will be de-risked by validating design parameters (such as manufacturing technique, material selection, material thickness, individual subsystems) independently. Validation requires quantitative comparison between ‘outcomes’ from experiment and the model. Preferably these outcomes will be performance indicators of the mechanism (such as hysteresis during moving mode), but may also be properties which are easier to test and model (such as modal analysis and strain distribution). Validation is an iterative process whereby the model is improved until experiment and theory agree well within their respective uncertainties.

Once the model is validated it can be used to optimise the design of the mechanism. The optimisation should minimise the uncertainty contribution of the mechanism when combined with other balance subsystems, and take into account manufacturability and ease-of-alignment.

The final step is validation of the optimised design, ie. fabrication and experimental verification of the final design. If it is found that there is significant deviation between model and experiment, the model must be adapted and optimisation re-run.

References

[1] BIPM, “Mise en pratique for the definition of the kilogram in the SI,” 2010.

[2] B. P. Kibble and I. A. Robinson, “Principles of a new generation of simplified and accurate watt balances,” Metrologia, vol. 51, pp. S132–S139, 2014.

[3] I. A. Robinson, “Simplified fundamental force and mass measurements,” Metrologia, vol. 53, no. 4, pp. 1054–1060, 2016.

[4] I. A. Robinson, “Towards the next generation NPL watt balance,” CPEM 2016 - Conf. Precis. Electromagn. Meas. Conf. Dig., pp. 1–2, 2016.

Student; Charlie Jarvis