High Speed Laser Cutting

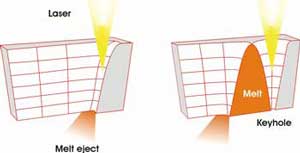

High speed laser cutting offers substantial economic benefits to the manufacturing sector. Laser cutting in the high speed regime operates with a different process mechanism to conventional laser cutting. This mechanism has a much higher coupling efficiency and potentially a corresponding increase in performance.

|

Aims

Laser profiling of thin sheet metal (0.5mm to 1.0 mm) has major applications in many industries, not least automotive and white goods. If the cutting rate, accuracy and cut quality can be improved to a sufficient level, laser cutting can be used in place of some punch press operations. Commercial implementation of the process would result in reduced time to market and lower tooling costs for these industries.

Areas of investigation

- Dynamic control of laser polarization

- Development of optimised laser nozzles

- Design of nozzles specifically applicable to the process

- Utilization of diffraction limited optics on high quality beams

- Examination of the gas/kerf interaction

- Application of non axially symmetric cutting configurations

This was then expanded to include the monitoring and control of laser beam parameters as a high degree of cutting performance dependence was observed.

|

|

|

|

|

Conclusions

The cutting speeds for optimized laser cutting have been pushed to the limits, with speeds in excess of 40m/min for 0.95mm automotive steel. It has been demonstrated that computational fluid dynamic modeling on laser kerf interactions must be 3D and not the more common 2D if it is to be meaningful for analysing laser processing.

Instigation of the high speed mechanism on plate thicker than 0.7mm has been very unreliable using this configuration, and an alternative optical source needs to be explored.

Collaborators

- BOC Gases

- Umicore

- Ferranti Photonics

- Corus

- Laser Expertise

- Stoves Ltd

- Vosper Thorneycroft

Funding

Researchers

- M. Sparkes

- W. O'Neill

- C. Rand

- I. Arokiam

- P. Farr

Duration

1999 - 2003