Discrete Computational Simulation for Manufacturing

Computer simulation tools are key to the modern model based enterprise following a “right first time manufacturing” approach. However, the industrial use of Laser Materials Processing (LMP) simulation is currently limited, due to the unavailability of a comprehensive and general model and the computational effort involved in solving the necessary transient equations.

Advancement in the understanding of LMP itself and the ability to predict the outcome of a processing operation will be of significant importance both to the traditional engineering application areas (e.g. cutting, welding, cladding) and to problems in fields such as biomedical engineering (e.g. lab-on-chip), microelectronics (e.g. Micro-Electro- Mechanical Systems or MEMS) and nuclear energy (e.g. inertial fusion targets). For low volume production or one-off situations where the workpiece may be unique and/or intrinsically valuable, such as the production of aerospace components or the restoration of archaeological artifacts, the predictive capability of a computer simulation tool would be invaluable.

The Discrete Computational Simulation for Manufacturing project aims to build upon previous simulation research and create an industrially realisable toolkit.

Objectives

- Research and develop a modelling suite, which, at some point, will be capable of simulation the laser cutting process without simplification and bias to perceived understanding

- Uncover forcing and feedback phenomena in the processes

- Consolidate the efforts of the international community

- Increase the understanding of the process in the field and aid new developments

- International collaboration and dissemination

- Group modelling support

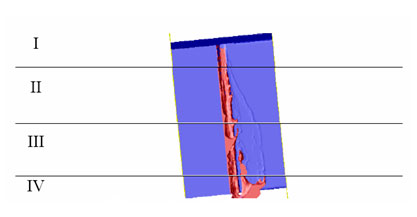

Melt dynamics in 6mm thick sheet

|

|

|

|

|

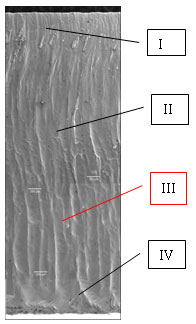

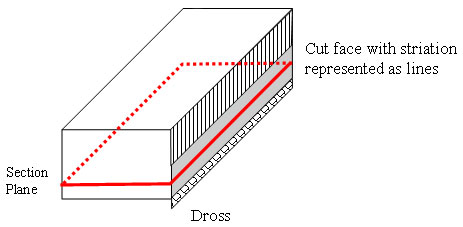

Wave-like melt deposits on kerf wall |

End of project summary

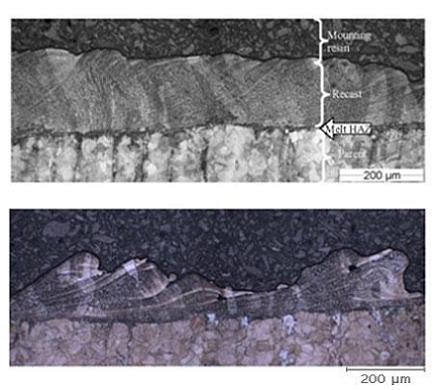

The Discrete Computational Simulation for Manufacturing project closed in September 2008. During the course of this project the laser cutting model ftLMPs was developed further with an aim of reducing the runtime and increasing the physical formulation. This was achieved in part by changing the underlying numerical methods and introducing fast iterative solvers. The multiphase paradigm was changed from VOF to level set and raytracing for beam propagation was added. In course of the development a simplified version was set up. This was initially solely motivated by for testing purposes; however, it generated such interesting results when married with experimental metallurgical results that it was taken further, leading to a peer reviewed journal publication. For ease of use by the less computationally oriented user this paradigm was translated into scripts for the commercial Computational Fluid Dynamics code Fluent and publicised in the context of the TCDA workshop (3-5 September 20008, Valencia, Spain – www.ifm.eng.cam.ac.uk/laser).

Modelling strategies new to LMP simulations were also followed up and developed. An example is the application of SPH methods, which is very promising because it can handle the intricate surface geometry as well as the spray breakup observed in laser cutting.

Publications

- Sparkes, M. and Gross, M. and O'Neill, W. (2008), A novel non-intrusive sampling technique for CO2 laser on-line beam monitoring utilising a silicon mirror, Optics and Lasers in Engineering, 46 (8). pp. 620-627. ISSN 0143-8166

- Sparkes, M. and Gross, M. and Celotto, S. and Zhang, T. and O'Neill, W. (2008), Practical and theoretical investigations into inert gas cutting of 304 stainless steel using a high brightness fiber laser, Journal of Laser Applications, 20 (1). pp. 59-67. ISSN 1042-346X

- Gross, M. S. and O'Neill, W. (2007), New aspects of melt flow phenomena through narrow kerfs, Journal of Physics D: Applied Physics, 40 (4). pp. 1201-1205. ISSN 0022-3727

- Gross, M. and O'Neill, W. (2005), How far is it worth simulating laser materials processing?, The Industrial Laser User (39). pp. 10-11. ISSN 1366-963X

Researchers

Duration

2004-2008