Case study: Maintenance of vessels in an effluent treatment plant

Background

This case study was conducted to demonstrate the complex nature of fleet maintenance planning.

The system considered in this study is part of an effluent treatment plant in an oil refinery. This refinery is one of the largest and most complex refineries in the Europe, processing over 250,000 barrels of crude oil per day. The refinery is situated on the sea because of two main reasons. Firstly, this location facilitates the transportation of crude oil to the on-site marine terminal. Secondly, the refinery operations necessitate drawing a large amount of sea water, mostly for cooling purpose. The processed water needs to be purified before it is returned to the sea.

The aim of this support system is to ensure that the purity of the filtered water meets environmental standards set by the government. This means that if this system does not operate at a required capacity, it will directly disrupt other refinery processes. Since the system is used to filter water from multiple refinery systems, different numbers of asset breakdowns lead to different economic consequences for the plant. This is because the operations of different systems will be shut down.

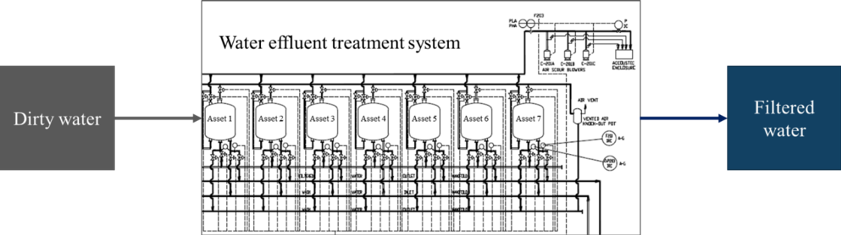

As shown in the figure above, the effluent treatment system consists of seven vessels. Although each vessel can work independently, five of them are required to operate together to satisfy the total demand of the plant. Moreover, the filter process necessitates that a vessel be carried out through a cleaning process at a fixed time period. In other words, the system can operate at full throughput with one vessel out of service (failure or maintenance).

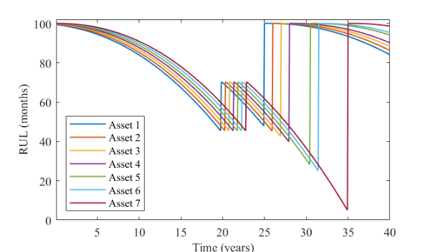

The oil refinery was facing a major problem as the internal lining of the vessel corrodes over time and deteriorates to the point that it cannot protect the vessel wall. Nonetheless, the lining deterioration cannot be detected from the outside. An internal inspection requires a vessel to be uninstalled and incurs high downtime and labour cost. Currently, there are two available maintenance options: patch repair and vessel replacement. As with an internal inspection, both maintenance activities also induce high cost and downtime. A patch repair can take place only once throughout the lifetime of a vessel due to the internal structure of a vessel. The current policy is run-to-failure, which leads to a high risk of production loss, especially when a vessel is uninstalled for maintenance while the others are in poor conditions.

Approach

We formulated a mathematical model that captures and explicitly demonstrates dynamic risk of production loss according to the aggregate output of multiple assets. Further, we developed an integrated solution method that couples a finite loop search with a Genetic Algorithm to devise an effective maintenance plan.

Benefits

Our model outperformed the current run-to-failure (RTF) strategy and binary multi-component k-out-of-N (BMC) approaches in the literature. It results in a 25% reduction in the total cost over the lifetime of the system. A further investigation shows that RTF incurs the lowest maintenance cost but leaves the system highly vulnerable, whereas BMC is the least risky strategy but leads to an overprotective strategy.

Researchers

- Sanyapong Petchrompo

- Hao Li

Publications

- Petchrompo, S., Parlikad, A.K., “Heuristic optimisation for multi-asset intervention planning in a petrochemical plant,” In Proc. 7th International Conference on Through-Life Engineering Services, Cranfield, 7 pages, Nov 2018.