Updates

Dear Collaborators and Colleagues,

Given the amount of interest and reach we had on our updates, for which we are extremely grateful, we decided to move our research updates to LinkedIn, which is subscribable.

Please take a moment to follow this page and do not hesitate to get in touch!

***

January 2023

We are joining AI UK organised by the Alan Turing Institute, to showcase some of the Lab’s research. Please come and see our stand if you are around!

SCAIL co-organised the first workshop on interdisciplinary firm-level networks with Oxford INET and Complexity Science Hub in Vienna. The 3-day workshop brought experts on supply network reconstruction and modelling disruption dynamics, featuring a lively debate on how policy makers can help worldwide construction efforts. Please get in touch with SCAIL if you are interested in network reconstruction as we progress the state of the art in this area.

On that front, SCAIL is welcoming Andrea Bacilieri from Oxford INET for a seminar on: reconstructing firm-level input-output networks from partial information, on the 22 February. Email us if you are interested in joining this exciting talk!

Ge, Alexandra and Edward joined the Liverpool digital manufacturing week along with our parent lab, DIAL, to discuss how supply chain practitioners are utilising AI solutions in their businesses.

We welcomed Philipp Schaffer from RWTH Aachen, who is visiting us for his Masters thesis. Philipp is working on NLP methods for extraction of supply network maps from the world wide web.

Alex joined the TES conference at Cranfield to present our latest results on DOTES. We are continuing to make progress in spare parts logistics management by creating optimisation approaches for uncertain demand and supply in the aerospace industry.

Our recent papers include:

- Chauhan V.K., Mak S., Alomari M., Casassa L., Parlikad A., Brintrup A. (2023) Real-time large-scale multi-tier supplier selection and order assignments with penalty and dual-sourcing, Computers & Industrial Engineering

- Zhou H., Parlikad A.,Brintrup A. (2023), Data-driven maintenance priority recommendations for civil aircraft engine fleets using reliability-based bivariate cluster analysis, Quality Engineering

- Zheng G., Kong L., Brintrup A. (2023), Federated Machine Learning for Privacy Preserving Collective Supply Chain Risk Prediction, International Journal of Production Research

- Proselkov Y., Zhang J., Liming X., Hofmann E., Choi T.Y., Rogers D., Brintrup A. (2023), Financial ripple effect in complex adaptive supply networks: an agent based model, International Journal of Production Research

(Please click here for a more complete list of our publications)

We are pleased to announce that our new project funSNM is set to continue the work done in MET4FoF, starting in June this year. Together with NPL, MET4FoF investigated agent architectures for metrology and created uncertainty quantification methods for sensor drift detection using Autoencoders. Watch this space for more information!

Supply Chain AI lab held a 6-week summer study camp at the Heilbronn Institute for Mathematical Research for mathematics Ph.D. students in association with The Newton Gateway, spanning early July to mid August. Four problems were proposed, aligned with the Heilbronn’s mission to support national security, with approximately 30 PhD students spread across these projects. Alongside projects from industry and other academic institutes, ranging from vaccine supply networks to trustworthy autonomous vehicles, this year Alexandra Brintrup and Jack Foster led a project on food security and the global food supply-chain.

Starting at a kick-off event at the University of Bristol, 6 PhD students began working on the problem of identifying dependencies and risks within the global food supply-chain. Working with various datasets, the PhD students developed their skills in programming, complex network analysis, data handling, and machine learning. Students successfully created a program that allowed users to view a breakdown of UK imports and, using complex network analysis, and answer important food security questions such as “how do disruptions in country X affect food supply in country Y?”, or “how do disruptions in country X affect the supply of ingredient Z?”. The project feeds into our supply chain resilience building activities within the agrifood supply chain sector.

July 2022

We are excited to announce two new projects we are starting this year:

- CORES project (Collective Resilience Learning in Supply Chains), which is funded by the UKRI, is developing machine learning methods where supply chain members can collectively contribute to risk prediction. The project explores how predictions on emergent risk made by a single company differ from collective predictions, and how and when collective knowledge should be tapped into.

- ChattyTwins, funded by the Alan Turing Institute and Accenture, is exploring how multiple digital twins from different organisations can give collaborative decisions to improve systemic behaviour. Improved formalisations for distributed decision making are especially important in manufacturing contexts where local goals can be in conflict with global objectives, or when the two cannot be aligned due to information asymmetries.

Some of our recent papers include:

-

Bang Yong X., Brintrup A.(2022), Do autoencoders need a bottleneck for anomaly detection? IEEE Access

-

Bang Yong X., Brintrup A.(2022), Coalitional Bayesian Autoencoders: Towards explainable unsupervised deep learning, Applied Soft Computing.

-

Bang Yong X., Brintrup A.(2022), Bayesian autoencoders with uncertainty quantification: Towards trustworthy anomaly detection, Expert Systems With Applications

-

Edward Elson Kosasih, Fabrizio Margaroli, Simone Gelli, Ajmal Aziz, Nick Wildgoose & Alexandra Brintrup (2022) Towards knowledge graph reasoning for supply chain risk management using graph neural networks, International Journal of Production Research,

-

Wang, Tao, Peng, Brintrup, Kosasih, Lu, Tang, Hu (2022) Dynamic Inventory Replenishment Strategy for Aerospace Manufacturing Supply Chain: Combining Reinforcement Learning and Multi-agent Simulation, International Journal of Production Research.

- Petchrompo S., Coit D.W., Brintrup A., Wannakrairot A., Parlikad A (2022) A review of Pareto pruning methods for multi-objective optimization, Computers & Industrial Engineering

- Brockmann N., Kosasih E., Baker S., Blair I., Brintrup A., (2022) Supply Chain Link Prediction on an Uncertain Knowledge Graph, European Conference on Machine Learning and Principles and Practice of Knowledge Discovery in Databases (ECML PKDD)

- Proselkov Y., Herrera M., Hernandez M.P., Parlikad A.K., Brintrup A.(2022), The Value of Information for Dynamic Decentralised Criticality Computation, IMS/IFAC

We presented two papers in IFAC - MIM 2022 in June in Nantes:

- Brintrup A., Kosasih E., (2022), Digital Supply Chain Surveillance,

and special congratulations to Edward for winning the Commended Paper Award in the MIM 2022 Conference, with the following paper:

- Kosasih E., Brintrup A. (2022), Reinforcement learning for safety stock optimisation

As part of our collaboration with Zhejiang University, we are organising a special session in IFIP APMS in Korea on “Cognitive and Autonomous AI in Manufacturing and Supply Chains” and presenting two papers:

- Tang W., Brintrup A. (2022) Distributed Manufacturing for Digital Supply Chain: a brief review and future challenges,

- Peng T., Brintrup A. (2022) Dynamic job shop scheduling based on order remaining completion time prediction,

We contributed a chapter on “Digital Supply Chain Risk Surveillance”, to the exciting new book “The Digital Supply Chain” edited by Profs. Dmitry Ivanov and Bart MacCarthy and published by Elsevier.

In February we welcomed Dr. Ge Zheng, who joined us from Bournemouth University to conduct research on the CORES project, and Dr. Alex Yoo, who joined us from Imperial College to conduct research on the DOTES project

Farewell to Vinod who has joined Oxford University’s Department of Engineering Science. We will miss Vinod, who has contributed to our group so much over the years and wish him all the best!

Michaelmas 2021

It has been a while since our last update. Here are some of the things we have been working on:

- We kickstarted a collaborative research programme with Zhejiang University in sustainable supply chains through data analytics. Our kickoff meeting included seminars from Centre for Industrial Sustainability, MAG and Zhejiang, and discussions on how increasing industrial digitalisation may help sustainability goals of organisations and streamline operations,

- Our EUROMET project Metrology for the Factory of the Future (Met4FoF) came to a close with a workshop, which was attended by Xiang and Alexandra. As part of our research for Met4FoF, Xiang investigated how sensor uncertainty can be modelled for predictive applications in manufacturing and created a Bayesian framework coupled with an Agent Based Metrology approach - read more about Met4FoF here.

- Alexandra presented our latest research in supply chain AI during the INFORMS annual meeting which took place in California,

- Edward presented his research on Digital Supply Chain Surveillance at the Aviva research showcase. Find his podcast here

- Our recent papers include:

- A machine learning approach for predicting hidden links in supply chain with graph neural networks, International Journal of Production Research (by Edward)

- Will bots take over the supply chain? Revisiting agent-based supply chain automation, International Journal of Production Economics (by Liming)

- A hybrid-learning decomposition algorithm for competing risk identification within fleets of complex engineering systems, Reliability Engineering and System Safety (by Hang)

- The value of information for dynamic decentralised criticality computation, IFAC (by Yaniv)

- Coalitional Bargaining via Reinforcement Learning: An Application to Collaborative Vehicle Routing, NeurIPS (by Stephen)

- We welcomed PhD candidate Luca Mungo from the University of Oxford who presented his research on Reconstructing production networks with machine learning. We discussed how different approaches from AI and Complex Networks can help predict links in Supply Chains.

- Vinod and Alexandra visited Rolls Royce as part of our DOTES project to discuss how optimisation approaches can be used to improve the PCB assembly line optimisation process

- AgentChat is progressing. We held a workshop in the IfM, discussing how different agent based approaches can be used to improve collaborative vehicle routing problems with logistics service providers. Stephen and Liming showcased our latest AgentChat demonstrator in the Digital Manufacturing Week that took place in Liverpool. As driver shortages hit the UK, collaborative vehicle utilisation is gaining momentum. Our recent paper using deep multi-agent reinforcement learning to solve collaborative vehicle routing was also accepted into NeurIPS’ Cooperative AI Workshop 2021. Please get in touch with Alexandra or Liming if you’d like to explore more.

- Welcome to our new PhD students Leo and Jack! Leo (Lingxuan) joins us from Australian National University, where he studied Mechatronics Engineering. He will be working on the use of AI in supply chain finance. Jack has joined us via the AgriForwards CDT programme, and will be examining how graph-based machine learning approaches can be used to improve food production.

- Farewell to Stefan Schoepf and Jie Zhang. Stefan has worked on the AgentChat project, and developed learning approaches to the challenging problem of 3D container loading. Jie worked on Supply Chain Digital Twins, as part of PitchIn. Wishing all the best to Stefan and Jie!

June 2021

- Our paper entitled "Graph Representation Learning for Predicting Hidden Links in Supply Chain Networks" has been accepted for publication in ICML ML4Data workshop. The study presents a novel representation of supply chains as a heterogenous knowledge graph for training relational graph convolutional neural networks. Our algorithms can locate hidden links and dependencies in this knowledge graph and demonstrate state of the art results.

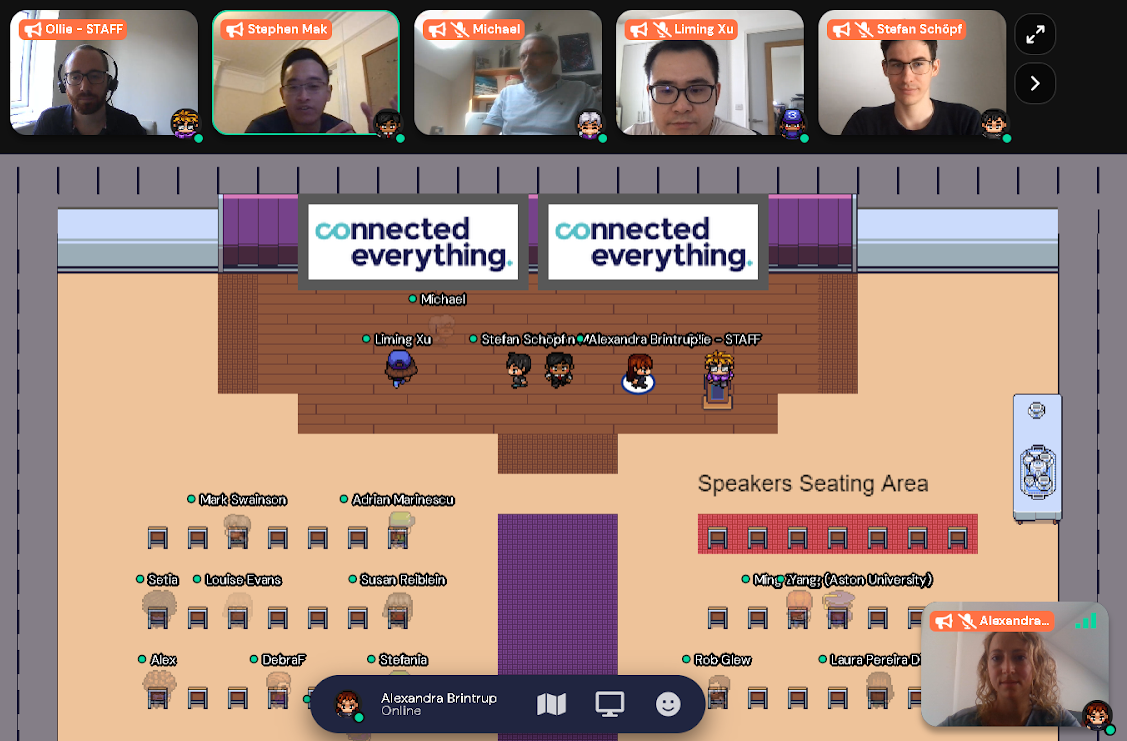

- Liming, Stephen, Stefan and Alexandra presented preliminary findings from our AgentChat feasibility study at the EPSRC Connected Everything Festival, together with Value Chain Lab. We are currently exploring optimality gaps and scalability trade offs between centralised orchestration of truck sharing, and plans achieved by self-interested agents. Read more about AgentChat here.

- Watch our final PitchIn Manufacturing event here. The event brought our work in PitchIn to a close, and was attended by more than 100 participants from academia and industry, where researchers from Cambridge, Oxford, Sheffield and Newcastle discussed how latest research in manufacturing IoT and its uptake by industry

- We welcomed Dr. George Bargiannis from Huddersfield University, who gave a seminar on Supply Chain AI, raising important issues around explainability and interpretability.

- Alexandra joined a panel discussion on the convergence of Blockchain and AI at Blockchain for Europe Summit #EU4BC, which touched upon benefits of blockchain in supply chain and logistics operations and the role of AI.

- We will be presenting our work in Supply Chain Artificial Intelligence at the upcoming Informs annual meeting in October in Anaheim, CA.

- Alexandra presented our group’s work on Supply Chain Artificial Intelligence at the EmLyon Business School. The seminar generated discussions around how AI can be used in Supply Chain business processes, and how new business processes may need to be designed for effective integration.

March 2021

Happy Easter from all of us! As we enter the Easter term, some of our recent updates include:

- Welcome to Stefan Schoepf, who joins us from ETH Zurich to conduct his Masters Thesis project on Collaborative Logistics Optimisation. Stefan investigates the interesting problem of container packing when a vehicle is shared by multiple shippers.

- 2 MET2b students are carrying out their integrated projects with us. Brian Lee is investigating the challenge of supplier price prediction and James Lloyd is studying the different ways in which distributed manufacturing platforms operate digitally.

- Yaniv and Alexandra presented at the annual CASN-RA meeting to share thoughts on our collaborative project with Arizona State University and the University of St.Gallen on Digital Supply Chain Financing.

- We participated in the EPSRC ECF meeting in January to discuss industrial impact of Manufacturing Research in the UK.

- Vinod and Hang presented their work at the DOTES project quarterly meeting, discussing how predictive modelling and supply chain optimisation solutions could help improve asset lifecycle management practices. Find out more about DOTES here.

- We are presenting our paper entitled “Module Failure Feature Detection by Cluster Analysis for Fleets of Civil Aircraft Engines”, at the INCOM 2021 - 17th IFAC Symposium on Information Control Problems in Manufacturing.

- MAG is welcoming Dr. George Bariannis from Huddersfield University who will give a talk on the explainability of AI research on the 6th May 2021. Please get in touch with Vinod Kumar, vk359@cam.ac.uk if you’d like to join.

November-December

Merry Christmas everyone! As we entered the holiday season, some of our recent news were:

- Our paper entitled "Learning with Imbalanced Data in Smart Manufacturing" has been accepted for publication in IEEE Access. The study addresses the challenge of imbalanced data in manufacturing applications by comparing extant techniques proposed in literature and proposing a comprehensive framework that considers data preparation, pre-processing, classifier design, and post-processing.

- Our paper entitled "How does the position of firms in the supply chain affect their performance? An empirical study" has been accepted for publication in Applied Network Science.The paper discusses the relationship between the topological position of firms in complex supply networks and their performance, finding the diminishing returns relationship between a supplier's centrality and its performance.

- Our new book chapter entitled "Artificial Intelligence in the Supply Chain: A Classificaiton framework and Critical Analysis of the Current State" has been published in the Oxford Handbook of Supply Chain Management, edited by Thomas Y. Choi, Julie Juan Li, Dale S. Rogers, Tobias Schoenherr and Stephan M. Wagner. The chapter conceptualises the topic of Supply Chain AI thorugh a human-mimicking intelligent agent that exhibits spart supply chain behaviour, and reviews its capability blocks.

- We participate in the Digital Manufacturing Week showcasing both the AgentChat project and the PitchIn Autonomous Supply Chain demonstrator.

- Alexandra participated in the Sheffield TechExpo panel on IoT to discuss how IoT can help with Manufacturing and Supply Chain resilience. Discussions centred around how 5G, and Cybersecurity challenges may impact the successful adoption of IoT.

- Our weekly Pitch in webinars came to a close, having generated lots of good discussion around IoT in Manufacturing. We will be rerunning the series in the Spring to report on project mini-project results - please get in touch if you are interested in joining. More information on Pitch-In mini-projects are found here

September-October

- Welcome to Michaelmas 2020!

- Congratulations to Edward Kosasih, who has passed his MPhil viva. Edward’s dissertation focused on the use of Reinforcement Learning (RL) approaches for safety stock optimisation, finding that RL offers flexibility to incorporate more realistic optimisation set ups and allows for innovative solution emergence, as compared to traditional approaches.

- Congratulations to Dr. Tim Pearce, who has passed his PhD viva. Tim’s research contributed to the field of Bayesian neural networks by providing methods that enable uncertainty quantification in deep learning while remaining very practical and scalable – which is a primary concern in assessing the applicability of AI in real-world engineering problems.

- Welcome to our new PhD student Wangchujun Tang, who will work on distributed multi-agent systems for decentralised supply chains.

- Our paper entitled “The relationship between nested patterns and the ripple effect in complex supply networks” has been published in the International Journal of Production Research. In this paper we analyse the effects of nestedess on supply chain disruption cascades. ‘Nestedness’, is defined as a pattern of organisation where products that are supplied by specialist suppliers are a subset of products that are supplied by generalist suppliers. In other words, generalists are also specialists. We find that nested organisations are significantly more robust to random disruptions but vulnerable to hub disruptions under cascade conditions. However, nested structures are not as resilient; as they do not benefit from a response strategy where buyers seek alternative suppliers; because alternative suppliers do not exist.

- We showcased our Autonomous Supply Chain demonstrator, developed in collaboration with Fetch.ai during an online webinar which has attracted more than 85 participants, leading to discussions around how agent based system approaches could couple with digital currencies. Find more about the project here.

- We are going to participate in the Digital Manufacturing Week to discuss the Pitch In and AgentChat projects - come and speak to us!

- Our first Data Study Group in Agrifood supply chain resilience took place virtually in September, with 30 researchers from across the UK. The study has been facilitated by the Isaac Newton Institute of Mathematical Sciences and the Knowledge Transfer Network. We have started creating methods to identify products and countries that are the most critical among the UK’s agricultural network dependencies and to understand how these dependencies evolve over time. For more information please contact: ab702@cam.ac.uk

- We are starting weekly webinars on Pitch-In Manufacturing mini-projects, and have an exciting series of 16 mini-project presentations. Please get in touch if you’d like to know more.

June - July:

- We are presenting two papers at ICML this year: "Bayesian Autoencoders: Analysing and Fixing the Bernoulli likelihood for Out-of-Distribution Detection" by Xiang, and "Structured Weight priors for convolutional neural networks" by Tim.

- Yaniv will present his paper on "Distributed Dynamic Measures of Criticality for Telecommunication Networks" in the upcoming SOHOMA

- Liming, Stephen and Alexandra presented our recent work on the AgentChat project in the Connected Everything Conferencein July.

- We are organising a data study on the UK’s resilience to supply chain shocks in the Agrifood Sector. This study group will take place over two sessions. This first session (7 – 8 September) aims to assess the resilience of the UK food networks, while a second session later in the year will take the representations and learning from session one to look the UK food network response to specific shocks. The event is organized by us, Queen Mary, Knowledge Transfer Network, Isaac Newton Institute for Mathematical Sciences and the Alan Turing Institute. We are particularly interested to hear from researchers in data science, statistical modelling and network science. Please contact ab702@cam.ac.uk if you are interested in taking part.

- Boyang Song from the University of Sheffield, introduced us to his work on “ An Industrial Internet of Things (IIoT) & Deep Learning approach for Predictive Maintenance (PdM)". As part of the Pitch In project we are collaborating with Sheffield to understand how machine learning approaches can be used to improve data challenges in manufacturing quality control.

April - May:

- As the Covid-19 pandemic hit the world, like most other research groups, we moved to remote working. While our research largely goes on without interruption, we are undertaking a number of activities to help combat the crisis:

- First of these is the setting up of an AgriFood Resilience forumwith UK’s Mathematical Sciences Research Community. The forum, organised by the Innovate UK and Knowledge Transfer Network will discuss ways in which UK’s Mathematical Sciences community can help combat disruptions to the UK’s food supply and logistics. The forum has published its first report and then gave its first webinar on the 28th April, attracting more than 130 participants. As part of the webinar series we presented how Network Science and Modelling can help understand disruption risks in large scale supply systems. Find more details

- Group members have participated in IfM’s Covid-19 taskforce, which includes the development of simulation models to predict patient flows and capacity at Addenbrookes Hospital. Find more about IfM’s initiatives on Manufacturing and Covid-19

- We are starting a very timely new project with Aviva on supply chain risk. The project will investigate how rare, catastrophic events can be modelled and how insurance providers can help businesses combat interruption.

- Stephen shared a best presentation award with two other researchers at the annual IfM PhD Conference. Many congratulations to Stephen!

- Edward was selected to participate in the prestigious Max Planck Pre-doctoral School 2020 taking place in Cornell, Maryland.

- Our collaborative research with Cranfield University on Aerospace Ecosystem Networks has been published in PLOS ONE: Jose LA Jr, Brintrup A, Salonitis K (2020) Analysing the evolution of aerospace ecosystem development. PLOS ONE 15(4): e0231985.The paper investigates how network patterns emerge and change over time, comparing countries with developed and emerging Aerospace industrial sectors.

February-March 2020

- Liming Xuand Stephen Mak won a feasibility study grant from the UK Connected Everything Network. Our new project, AgentChat, will explore the feasibility of enabling freight co-loading using agent-based technology. Although the idea of freight co-loading has been around since sometime, its implementation has been challenging due to information asymmetry and difficulties involved in manual orchestration: co-located or close suppliers do not know whether they are sending items to similar locations around the same times unless someone tells them. Third-party mediation only works if sufficient agents sign up, and retailers or logistic providers incur transaction costs for orchestration. Our approach will explore how distributed, automated solutions can tackle this problem and what information infrastructures need to be in place for it to be adopted.

- Many congratulations to Edward and Stephen who won first prize in the Aviva Data Science Hackathon organised by the Cambridge University Data Science Society!

- Xiang and Yasmin will be presenting our paper in the IEEE Metrology for Industry 4.0 and IoT conference taking place in Rome in June 2020. The paper details the development of a Bayesian Autoencoder for detecting drift in industrial sensor data-based prediction.

- Welcome to Dr Jie Zhang, who joins us from Greenwich University to work on the Supply Chain Digital Twin project.

- Edward discussed his research at the Indonesian Current Affair Discussion held in Lady Margaret Hall, Oxford, exploring the philosophical idea of a virtual twin and how it is related to Digital Twinsof today.

January 2020

- Welcome to 2020! After the Christmas break, we had a great start to the new year.

- Our new paper entitled “Extracting supply chain maps from news articles using deep neural networks”, has been accepted for publication in the International Journal of Production Research. The paper details Pascal Wichmann’s PhD research in the use of Natural Language Processing for automatically generating Supply Chain Maps from publicly available data. This work has led to the exciting spin-off called .

- Our new paper entitled “Uncertainty in Neural Networks: Approximately Bayesian Ensembling” will be presented by Tim Pearce at the upcoming 23rd International Conference on Artificial Intelligence and Statisticson June 3 - 5, 2020 Palermo, Sicily, Italy.

- The first Pitch in Manufacturing Day was held at the IfM on 11th December. With 25 participants from Cambridge, Sheffield, Newcastle and Oxford; we discussed the role of IoT in: Enabling new business models, Integrating data across digitally enabled Supply Chains, and novel analytics applications such as quality prediction, and automation of IP licensing payments. Discussions also centred on how IoT can be adopted by SMEs, and how IoT can be integrated with legacy systems.

- Our quarterly DO-TES meeting has been successfully completed at Ansys in Sheffield- we are pushing the boundaries of digital spare parts prediction and planning with use cases from Rolls Royce.

- Value Chain Lab has visited us to present their freight collaboration solution approaches and we discussed how agent-based systems could help with supply chain operations planning.

November 2019

- We are partnering with Fetch.ai to develop use cases in Smart Supply Chains. Fetch.ai is a Cambridge based AI and blockchain company that is building an innovative platform for connecting IoT devices and algorithms to enable collective learning. MAG’s research in multi-agent-based supply chains are a perfect match to Fetch.ai’s vision of democratic, decentralised data and AI. Stay tuned to find out more!

- Luiz Fernando Bittencourt, from the University of Campinas (UNICAMP), Brazil, gave a seminar on “Cloud Computing, Fog Computing, and Internet of Things: Data Processing for Smart Environments in the Era of Industry 4.0” - resulting in exciting discussions around how trade-offs between the computational cost of communication, memory and speed can be addressed via distributed computational layers and how these new architectures may help enable smart manufacturing and supply chains.

- Griffith Rees from the Sheffield Quantitative Methods Institute gave a seminar on modelling the effect of spatial contagion on the adoption of the pre-internet FidoNet network. FidoNet began in 1983 and peaked in 1995 with users across six continents and up to 5 million users in the US alone. It persists to this day but declined by an estimated three orders of magnitude. The seminar generated discussions around contagion models, and how learnings from FidoNet can be relevant to today’s social networking websites.

- Farewell to Jose Luna Andrade- who has been with MAG as a visiting researcher in the past six months. Jose has been working on developing an analytical approach for the evolution of countries exports and how competitive advantage can be benchmarked. MAG wishes all the best to Jose!

- Thiago, Hang and Alexandra visited Rolls Royce for our DOTES project - as part of DOTES, we are in the process of creating prediction models for remaining useful life estimation which is in turn used for optimising the spare parts supply chain. Find out more about the project here.

- Liming demonstrated the first version of our Autonomous Supply Chain platform at the Advanced Engineering Show in Birmingham. At the same show, Alexandra gave a talk on how IoT based Data Analytics can be used to create value in Supply chains and Manufacturing.

October 2019

- Our new paper “Supply chain data analytics for predicting supplier disruptions: A case study in complex asset manufacturing” is published in the International Journal of Production Research.

- Siddharth Arora from University of Oxford, gave a seminar on “From personalised medicine to decision-making for emergency care: Role of smart devices and analytics” giving interesting insights into how data-driven techniques can be used in predicting patient waiting times in emergency departments, which in turn can help improve overall patient satisfaction, and staff and resource allocation.

- Houyuan Jiang, from Judge Business School, gave a seminar on “Reconfiguration of Accident-and-Emergency Facilities in England”. His talk focussed on the use of queuing models for analysing cost and service implications of specialist and generalist facilities in hospital emergency departments.

- Welcome to our new research students Edward Kosasih,Stephen Mak and Yaniv Proselkov!

- Xiang presented his work on “Multi-Agent System for Machine Learning Under Uncertainty in Cyber-Physical Manufacturing System” at the SOHOMA’19International Workshop on Service-oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future. The theme of SOHOMA’19 Workshop is “Smart anything everywhere – The vertical and horizontal manufacturing integration”.

- Alexandra joined AI’s panel discussion on “Blurred Lines: The impact of AI in Business and Academia.” The discussions focussed on the role of regulation in ensuring transparency and ethical AI, and the challenges of integrating business-oriented and academic work in AI.

- Many congratulations to Dr Liming Xufor passing his PhD defence at the University of Nottingham!