Value engineering / value analysis

Aims to establish the cost of different elements of functionality and answer questions such as:

- "What is the cost of 'providing comfort' in a car"

- "What is the cost of 'mixing ingredients' in a bread mixer"

Whilst a relatively simple analysis, there is an underlying need to have an appropriate understanding of the needs and motivations of customers in order to consider the relative importance of product functions. Specific outcomes may include the elimination of excessive costs due to minor functions or the justification of increased cost for a highly important function. The best results enable an overall increase in functionality, without any increase in costs - added value.

Method

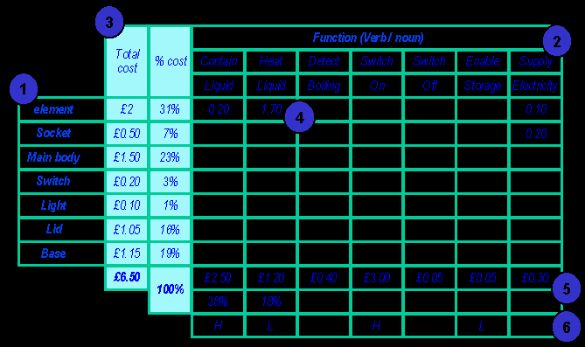

Identify components (or sub-assemblies for complex products)

Identify primary product functions - expressed as a verb and a noun

Estimate component (or sub-assembly costs and calculate the relative cost of each (%)

Estimate the value of each component

- so that the component cost is spread appropriately amongst the product functions to which it contributes. This can be difficult and it is useful to consider the perceived value to customers. It is at this stage that the team is involved in significant discussion and debate

Calculate the cost of each function and evaluate the relative cost of all functions

Investigate improvements

Can high cost parts be removed, identify high cost/low value and low cost/high value parts. Ask basic questions - eliminate, reduce, simplify, modify, standardise.

For more information, please contact:

T: +44 1223 764830