Insights

Top tips to get your firm fighting fit post-COVID

Leading experts advise how businesses can best prepare for the months and years ahead, and any future disruption that may come.

COVID-19: Manufacturing at a turning point

At this IfM Briefing, leading experts from the Institute for Manufacturing draw lessons from the response of firms and governments to the COVID-19 pandemic, and look at how the manufacturing industry is likely to change and adapt in the months and years ahead.

Helping SMEs towards digitalisation

Professor Duncan McFarlane provides an update on the progress of this high-profile project, developing low-cost digital solutions for SME manufacturers, with examples of some of the components developed so far.

The power of AI for supply chain efficiency

Dr Alexandra Brintrup shares key learnings from recent practical examples demonstrating how AI and data analytics can be used in supply chains to reduce disruption and improve efficiency.

Digital manufacturing, on a shoestring budget [WEBINAR]

This webinar introduces Digital Manufacturing on a Shoestring, an EPSRC-funded project, that aims to demonstrate how low-cost commercially available technologies can be exploited in SMEs.

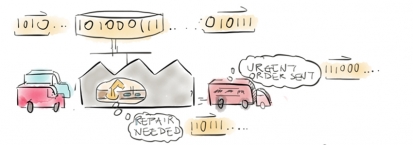

An IoT-based Smart Supply Chain Automation System

As part of the Pitch-In project, we are creating a platform that allows systems to 'talk' autonomously through the use of IoT and agent technology.

Assessing your automation investment decisions

Automation can be the answer to a whole host of manufacturing and operations questions. This webinar outlines the IfM's structured Automation Assessment Tool to support you in automation investment decision making.

Industrial Internet of Things - Connected Everything

As part of the Connected Everything project, at the University of Nottingham, Professor Duncan McFarlane championed the thematic research on the Industrial Internet of Things creating a report which is available to download.

Digital manufacturing on a Shoestring

In this article, Professor Duncan McFarlane introduces a new research project into low-cost digital solutions for manufacturing SMEs.

Factories of the future and implications for automation

Where will we make things in the future and how will the concept of a factory evolve? IfM's Professor Duncan McFarlane says that how we answer these questions is changing and is affecting our priorities for automation.

Introduction to the Industrial Internet of Things (IIoT)

Professor McFarlane talks about the next stage in the IoT evolution and its expansion into industry (IIoT).

Intelligent assets for the infrastructure of the future

IfM's Professor Duncan McFarlane (Head of DIAL) and Ajith Parlikad (Head of Asset Management) have co-authored an ICE (Institution of Civil Engineers) Guidance Paper on how new technologies will transform the infrastructures of the future.

Getting the most out of automation

Alan Thorne describes some of the work of the IfM's Distributed Information and Automation Laboratory (DIAL) and how it can help companies improve their automation systems.

Disaster relief operations

Earthquakes, tsunamis, floods and droughts: when a natural disaster strikes, relief organisations react by providing medical treatment, food, water and shelter. However, in these difficult and chaotic circumstances supply networks often prove to be insufficiently resilient.

Application of digital technologies to innovation in manufacturing

This report, commissioned by BSI (British Standards Institute), looks at how standards and good practice can help the UK benefit from the 'digital revolution'.

Big and clever: a system-wide approach to data analytics

The Distributed Information and Automation Laboratory (DIAL) at the IfM are working with companies such as Boeing, Exxon, Electrolux and Laing O'Rourke to develop smart ways of using data to improve performance and increase resilience.

A social network of things - New approaches to asset management

Dr Ajith Parlikad, Head of the IfM's Asset Management Group, explains how effective asset management can deliver significant value both for manufacturers and for infrastructure owners and operators.

DIAL B for Boeing

Duncan McFarlane, Head of the IfM's Distributed Information & Automation Laboratory (DIAL), and members of his research team have been working with Boeing since 2005, finding intelligent solutions to some challenging industrial problems.

Expecting the Unexpected

The key to long-term management of infrastructure lies in futureproofing, say Duncan McFarlane and Tariq Masood.

The future of flying

Aircraft that work together to solve complicated mathematical problems and airports with more flexibly used runways could be the future of flying, according to studies by University of Cambridge engineers and their industrial and academic partners.

The lost art of risk management

Dr Mukesh Kumar from the Centre for International Manufacturing suggests that multinational manufacturers are taking unnecessary risks with their industrial investments and he offers a solution.

The Origin of the Internet of Things

Most of you have probably heard the Internet of Things, or the IoT, mentioned but have you ever wondered what it means and where it all began?

What makes an intelligent infrastructure asset?

What would it take to enable a piece of infrastructure to take care of itself, asks Duncan McFarlane of the Cambridge Centre for Smart Infrastructure?

Total Information Risk Management: Maximizing the Value of Data and Information Assets

How well does your organization manage the risks associated with information quality?

Through-life management of industrial assets

Dr Ajith Parlikad will discuss the key challenges in asset management and the role of emerging information technologies in improving the way in which assets are tracked and managed.