High efficiency gas-assisted cutting using optimised next generation fibre lasers (HEGAC)

New Yb fiber laser sources are being developed in conjunction with the Optoelectronics Research Centre at Southampton University and SPI Lasers. These new laser systems offer even greater potential in future manufacturing operations.

Aims

|

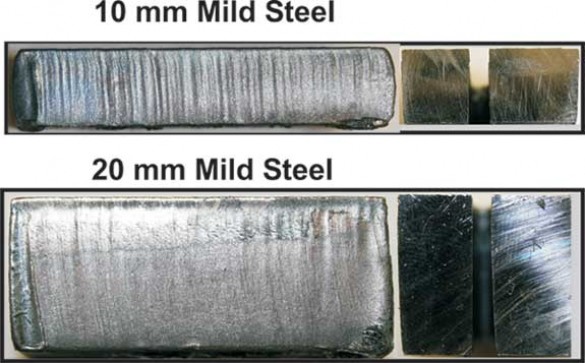

| Initial process trials - click on the picture for a larger view |

A new high-brightness, highly-efficient fibre laser will be uniquely tailored for precision oxygen-assisted laser cutting of both thin and thick sheet materials. A novel design and development of optical and assist gas handling system will enable this laser cutting technology to be cost effective with pollution levels lower than existing CO2 and YAG LASOX process, plasma, and flame processes and will provide the key incentive for the UK to take the lead in the multi-billion Euro laser, cutting tools, consumables, and ancillary markets.

Progress

- A high quality 400W CW fibre laser system has been developed by SPI Lasers.

- A unique 100W average power pulse laser system is being developed by the ORC with tuneable spatial and temporal characteristics.

- An optical system is being designed and developed by the ORC and the Centre for Industrial Photonics with highly tuneable spatial beam characteristics.

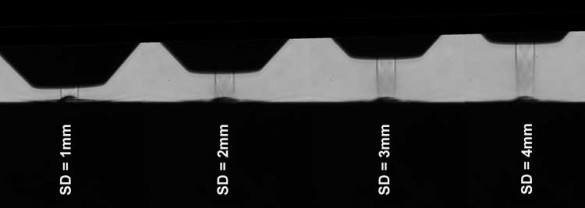

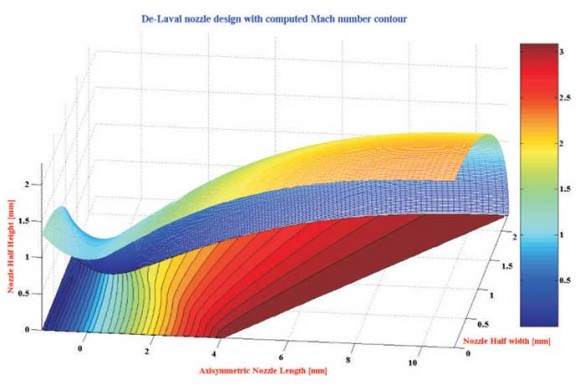

- A novel cutting head and supersonic gas stream handling system has been designed and developed by the Centre for Industrial Photonics for high efficient laser cut quality. Initial process trials have shown the system is capable of cutting 20mm mild steel with moderate 300W CW fibre laser. This has never been achieved before.

| Optical design - click on the image for a larger view |

|

|

|

Nozzle design |

Publications

- Khan, A. H. and Celotto, S. and Tunna, L. and O'Neill, W. and Sutcliffe, C. J. (2007) Influence of microsupersonic gas jets on nanosecond laser percussion drilling Optics and Lasers in Engineering, 45 (6). pp. 709-718. ISSN 0143-8166

- Tunna, L. and Khan, A. and O'Neill, W. and Sutcliffe, C.J. (2006) The effect of processing wavelength and fluence on the microdrilling of 316 L stainless steel with a diode pumped solid state laser Journal of Laser Applications, 18 (3). pp. 205-209. ISSN 1042-346X

- Khan, A.H. and O'Neill, W. and Tunna, L. and Sutcliffe, C. (2006) Numerical analysis of gas-dynamic instabilities during the laser drilling process Optics and Lasers in Engineering, 44 (8). pp. 826-841. ISSN 0143-8166

Collaborators

Optical Research Centre (ORC), Southampton University

Researchers

A. Khan

Funding

BERR

Duration

2006 - 2009