Disruption Tolerant Automated Lean Factories

Challenge

Enable stable and resilient operations across lean distributed manufacturing processes.

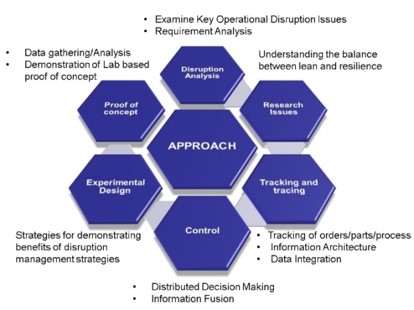

Project Objectives

- To identify the type and scale of disturbances impacting production operations at Boeing

- To propose improved methodologies to assess the balance between lean and resilience

- To propose how enhance track and trace concepts can be adopted within production control systems

- To demonstrate key developments through a lab based proof of concept demonstrator

Lean vs Resilient

Production Mathematical model developed that describes the operation of a production system in the face of disruptions

Outputs:

- Industrial guidelines for planning a resilient manufacturing system configuration (best buffers sizes, location of inspection points)

- Trade-offs in attempting to achieve both lean and resilient production

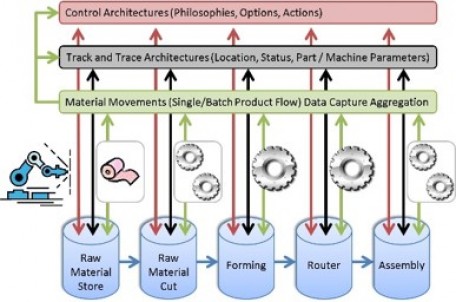

Tracking and Control of Resilient Production Tracking and tracing

- Enables timely visibility of production operation

- Full traceability of orders/parts/resources enabling root cause analysis

- Information architecture and data integration Control Mechanism

- Flexible distributed control system (disturbance detection, dynamic reaction for disturbance handling)

- Incorporates real-time tracking information into decision making

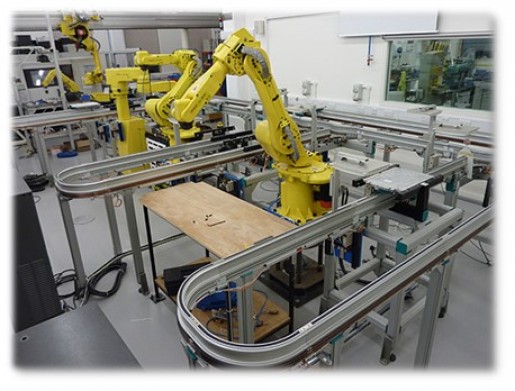

Proof of Concept Demonstrator

- To show the various disruptions that occur in process/assembly based manufacturing techniques To implement technological solutions to manage those disruptions and demonstrate the practical implications of disruption tolerant manufacturing process

- To demonstrate various lean vs resilient strategies and control architecture for disruption tolerant systems

Principal Investigator

Researchers

Jumyung Um

Project Partner

The Boeing Company