Industrial resilience audit

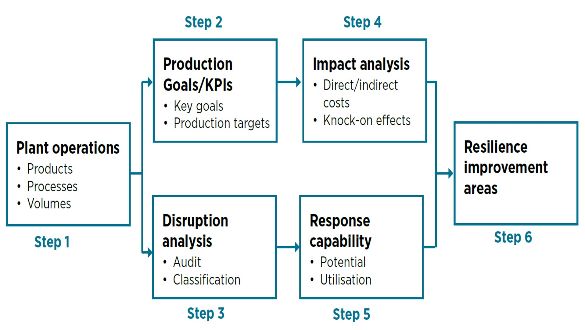

Diagnoses why processes are experiencing disruption and helps identify short-term fixes and define longer term plans to develop more flexible production processes.

The Industrial Resilience Audit identifies:

- Problems or disruptions that cause processes to underperform.

- How frequently processes suffer from the identified disruptions.

- The effect or impact of the disruptions on process performance.

- The resilience capabilities that processes have for handling the disruptions.

The output of the Industrial Resilience Audit can help:

Short-term internal activities

- Prioritise improvements to current processes (process capabilities, operational adherence & stability, material specifications.)

- Identify the requirement for new process capabilities to better cater for disruptions.

Long-term internal/external activities

- Focus the development of next generation processes.

- Providing flexible production capabilities, for new products, using new technologies, with changing business demands.

Industrial Resilience Audit approach

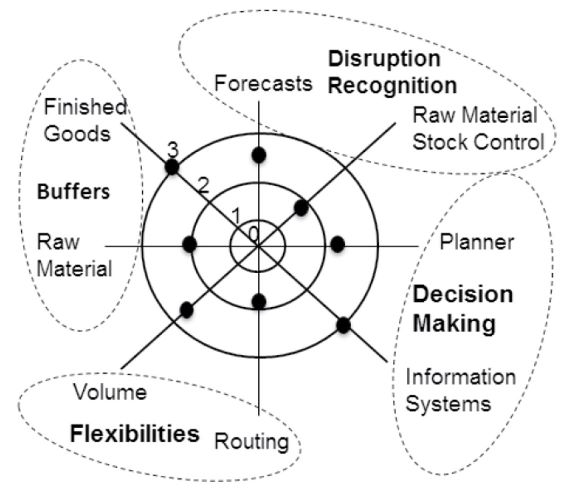

Resilience capability assessment

Previous work

Disruption analysis in this form has been applied to a range of operations:

Britvic, Alcatel, Unipart, ASW, Henkel

Airport Operations

EasyJet, Luton Airport

Agriculture

G’s Growers

More information

Please contact Professor Duncan McFarlane, E: dm114@cam.ac.uk T: +44 (0)1223 338069

For further information please contact:

Share This