Novel energy delivery techniques for laser additive manufacturing from metal powders

Current state-of-the art additive manufacturing machines are capable of producing any geometry from metal powders with

In the biomedical industry a typical example of a mass produced additively manufactured part is the acetabular shell. This is part of the hip joint which bonds the replacement to the body. The part has a highly complex porous structure on the outer surface aiding bio-integration. The current state-of-the-art manufacturing machines cost £0.5M upwards and produce around 6,000 of these parts per year. The demand in England and Wales alone is of the order of 80,000 per year, leading to a supply deficit of these high quality parts.

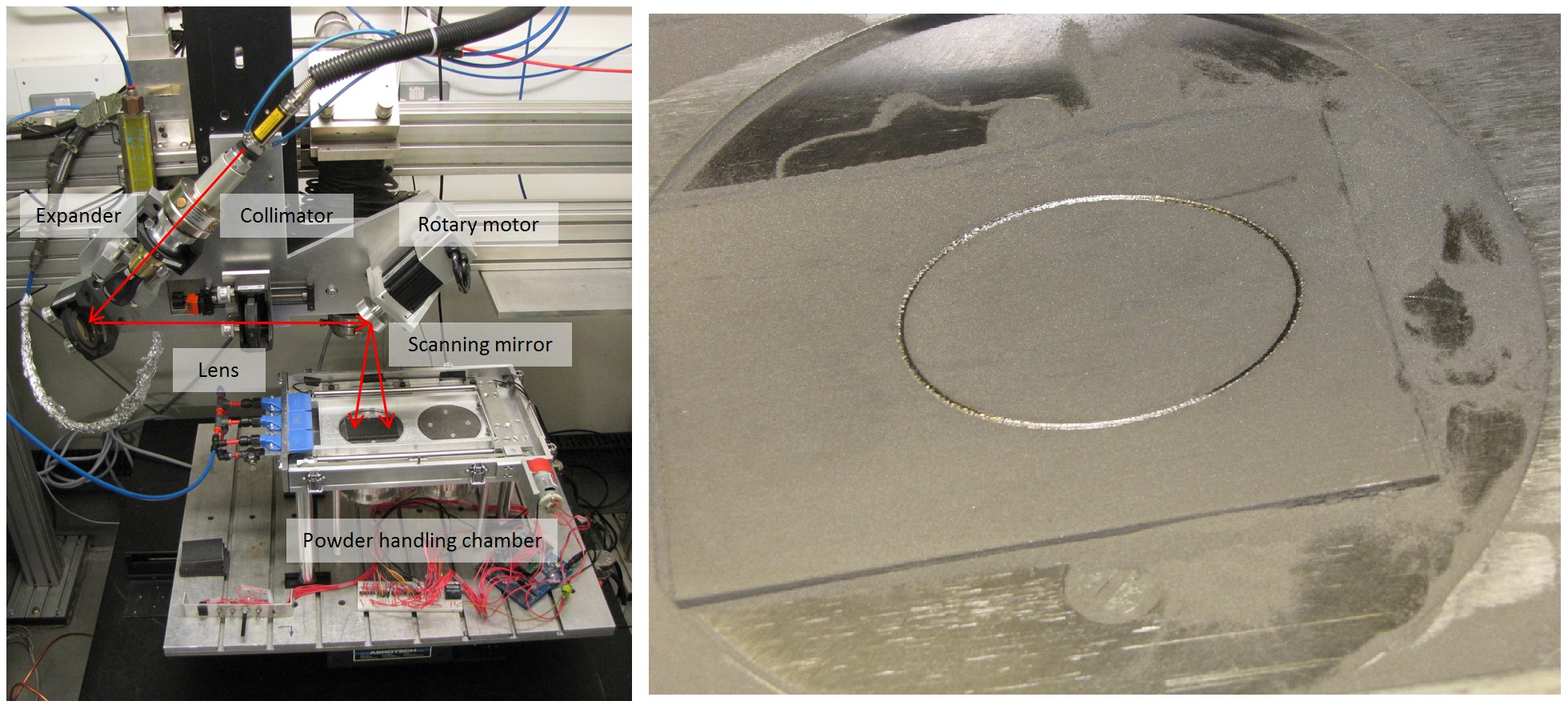

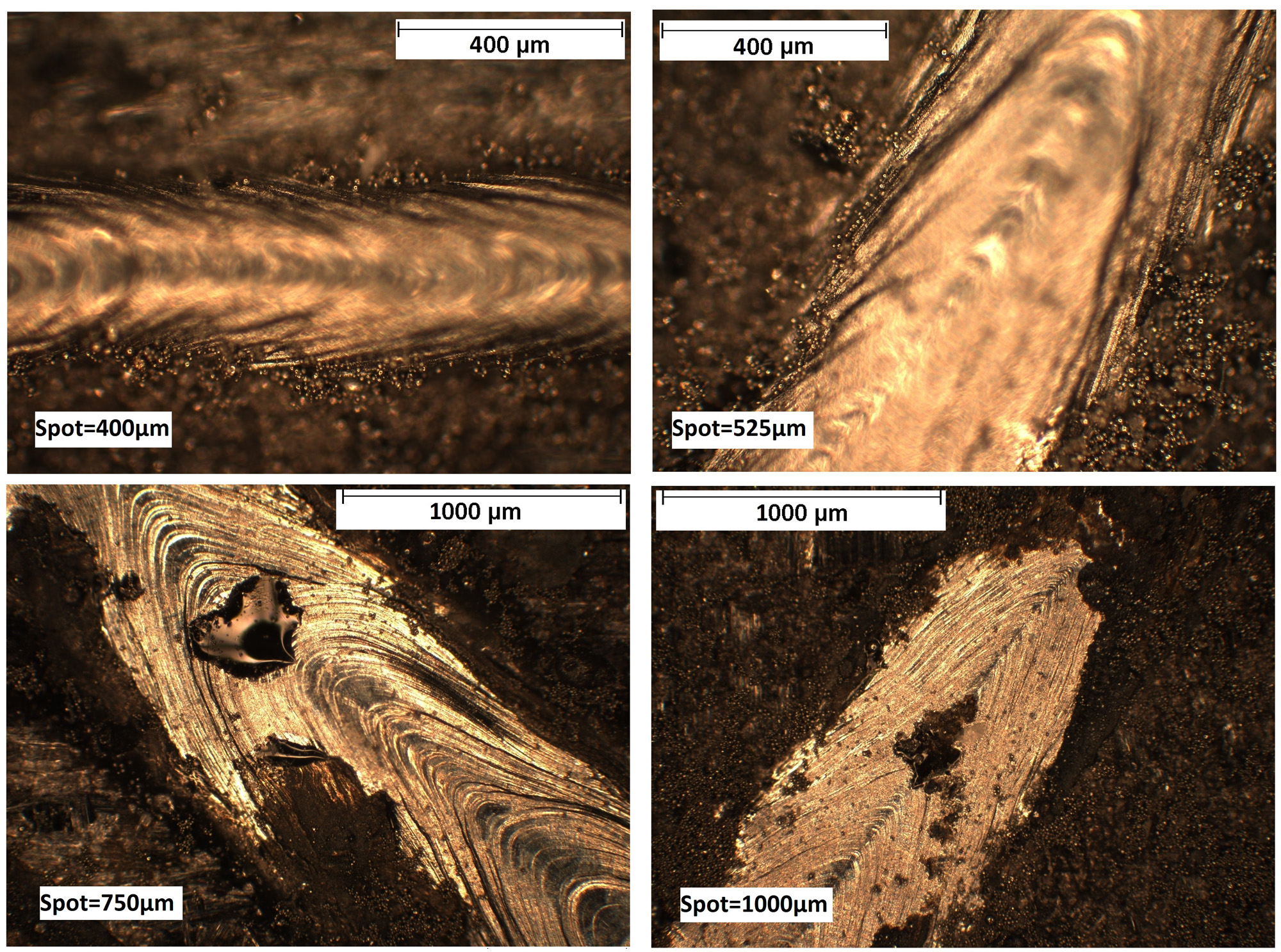

This project aims to determine the limitations of the existing process and identify new energy delivery methods to increase the throughput of laser melted parts. We have built a dedicated test system not constrained by the need for geometric freedom. This system can test the extents of the existing laser melting regime in terms of laser spot size, scan speed and laser power. The test system also enables new scan strategies to alter the temperature distribution in the powder.

Thermal gradients are one of the key limiting factors in laser additive manufacturing. Steep thermal gradients lead to localised shrinkage of parts during cooling. This results in large residual stresses in manufactured parts which can bend and crack the parts leading to failure. In-process thermal gradients in the liquid metal pool are likely key drivers of instability due to altered surface tension. It is hoped that reducing thermal gradients will improve melt performance and extend the available parameter space with larger beams and faster scanning. Heat delocalisation is being explored via several energy delivery mechanisms which it is hoped will be implemented into a new dedicated production machine for acetabular shells.