Case study: Industrial cold box unit in a petrochemical plant

Background

This case study was conducted to demonstrate our stochastic dependence models on state-rate interactions. The system under consideration is part of an industrial cold box unit in a petrochemical plant. We examined two gas tubes feeding excess-heated gas into the cold box unit. As the tubes are feeding the excess-heated gas into the cold box unit, fouling would occur within the tubes and consequently reducing the amount of heat which can be delivered into the cold box.

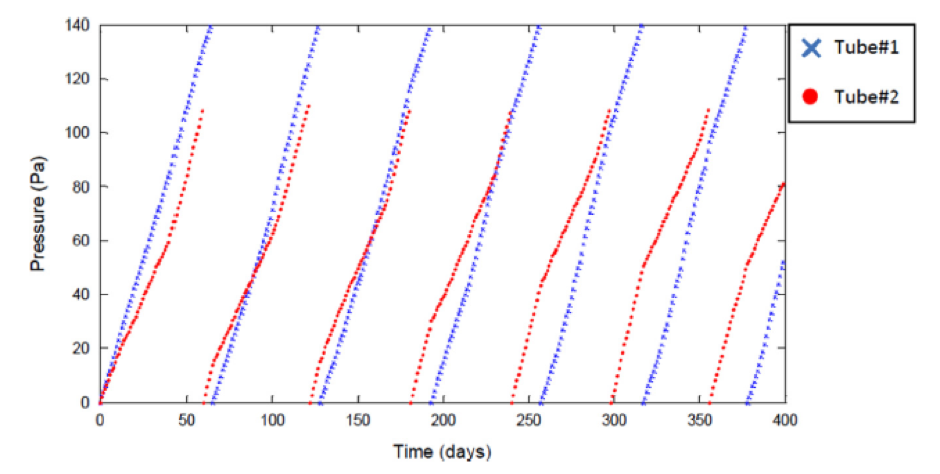

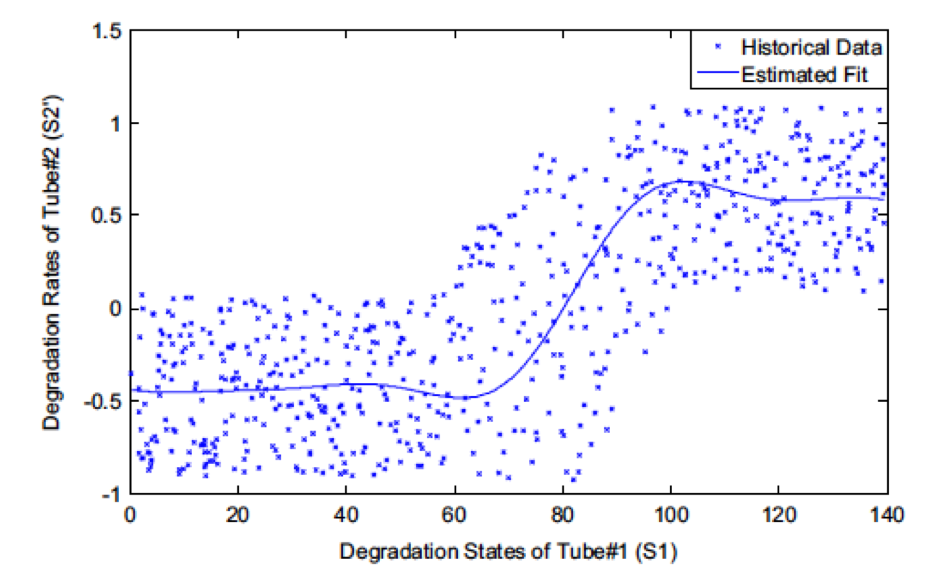

Pressures in the tube were measured to act as surrogates to the degradation states of a component at a certain time. Lower pressure would indicate less amount of fouling and more effective heat transfer into the cold box. As fouling occur during operation, the pressure would be increased on the tube and hence result in decreasing performance of the system. Degradation interactions between the two components can occur as when one tube is already subject to a high fouling state, the excess-heated gas would then be forced to go through the other tube and hence overloading that other tube which then leads to accelerated fouling as a result. This was reflected in the data collected from the plant.

Current maintenance policies of the system include a daily condition monitoring and the system is allowed to operate until the pressure of a gas tube exceeds the safety threshold level. The failed tube is then maintained, allowing the pressure level to reduce and increase the performance of the system.

However, this was not the optimal maintenance policy for the tubes because of the loss due to performance degradation of the system. By moving the maintenance threshold earlier than the safety threshold, the system would be reducing the loss due to performance degradation albeit with increased maintenance costs. This suggested that investments in more maintenance of the tubes may allow the system to reduce its average cost in the long term.

Approach

A regression model was used to characterise the state-rate degradation interactions between the two gas tubes. In particular, Gaussian Process Regression(GPR) was used for estimating the degradation functions. The interactive degradation model was then used to optimise the condition-based maintenance policy, which provided the inspection and maintenance thresholds in terms of the estimated reliability of the system. Optimisation was performed using Simulated Annealing.

Benefits

Our model resulted in a better condition-based maintenance policy for the cold box unit which reduced the long run cost of the system by 10%.

Researchers

- Nipat Rasmekomen

Publications

- Rasmekomen, N., Parlikad A.K., "Condition-Based Maintenance of Multi-Component Systems with State-Rate Degradation Interactions," Reliability Engineering and System Safety, Volume 148, pp. 1-10, 2016.