Case study: Fault propagation in power transformers

Background

This case study was conducted with a major power distribution company in Asia to improve the maintenance of a fleet of oil immersed power transformers of different ages.

Power transformers have high failure costs, and may cause catastrophic damage on the power network. The time required to maintain a transformer is non-negligible, and during this period the power network suffers a service reliability drop. Therefore, the availability of power transformers is normally deemed as the bottleneck of reliability and capability in power transmission systems.

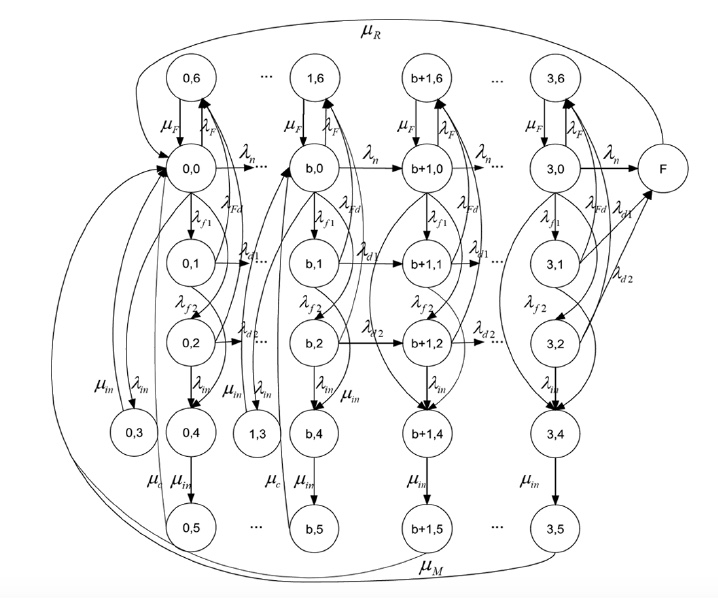

Power transformers consist of critical components such as winding insulation paper; and non-critical components such as cooling equipment, bushing, and tank. The life of a power transformer is primarily constrained by its winding insulation paper with an expected service life of 38 years. The winding paper insulation is subject to two types of accelerated deteriorations. Firstly, it is subject to accelerated chemical degradation, which is caused by aggressive pyrolysis, hydrolysis, and oxidation. The degradation

happens in the presence of decay agents such as water, oxygen, acid, and sludge. The excessive decay agents could be attributed to the malfunctioning of non-critical components, such as poor tank sealing, and inelastic gaskets in bushings. Under this circumstance, it could accelerate the aging to as much as 20 times.

Mechanical deterioration may be accelerated by an increase in the level of vibration, which is caused by malfunctions such as the loosening of clamps, or the distortion of the geometry of its winding. The lifetime of the winding insulation is approximately reduced to 8 months, under accelerated mechanical deterioration. The symptoms of accelerated deterioration can be detected by inspection, and remedy actions such as oil reclaiming, drying, de-sludging, reclamping, and repacking are performed to rectify accelerated deterioration. Power transformers also could stop functioning due to external incidents such as short circuits, switch transients, and lightning strikes.

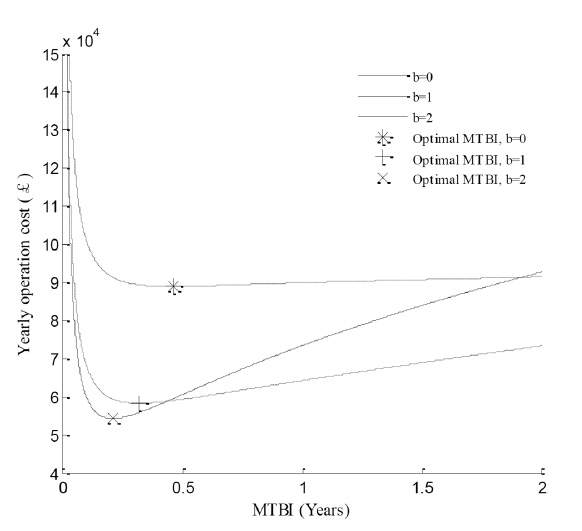

The aim of this study was to explore maintenance strategies and inspection strategies to maximize the availability and minimise the cost, by adjusting the major preventive maintenance threshold and mean time between inspections.

Approach

We modelled the transformer deterioration behaviour using a multiple dependent deterioration path model (MDDPM) constructed using a continuous time Markov chain (CTMC). By varying the mean time between inspections (MTBI) and the major preventive maintenance threshold, we are able to optimize the asset's performance in term of availability and cost.

Benefits

Due to the high failure cost and down time penalty, the savings from operations costs were significant – as much as 7% of yearly operations costs. Also. by developing a multi-criteria decision model, we examined the trade-offs between availability and cost – providing asset managers a powerful tool to make decisions effectively.

Researchers

Project Partners

- National Grid

- State Grid Corporation of China

Publications

- Liang, Z., Parlikad, A.K., "A Markovian Model for Power Transformer Maintenance," International Journal of Electrical Power and Energy Systems, 2018.

- Liang, Z., Parlikad, A.K., “A condition-based maintenance model for assets with accelerated deterioration due to fault propagation”, IEEE Transactions on Reliability, Volume 64, Issue 3, pp 972-982, 2015.

- Liang, Z., Parlikad, A.K., “A tiered modelling approach for condition based maintenance of industrial assets with load sharing interaction and fault propagation,” IMA Journal of Management Mathematics, Volume 26, Issue 2, pp. 125-144, 2015.