Social IoT for Machines

Challenge

The challenge addressed in this project is “how can we share data, information and insights across fleets of assets and perform system level maintenance optimization?”

Vision

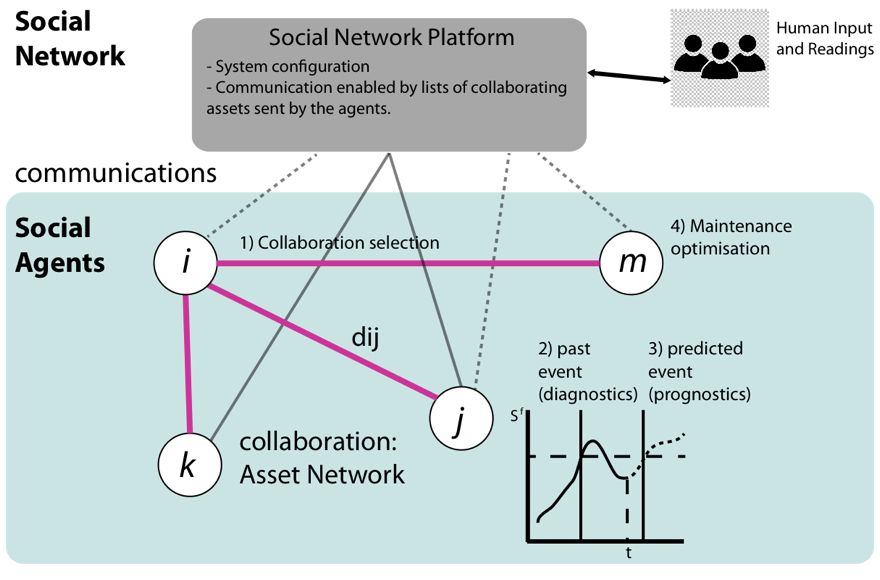

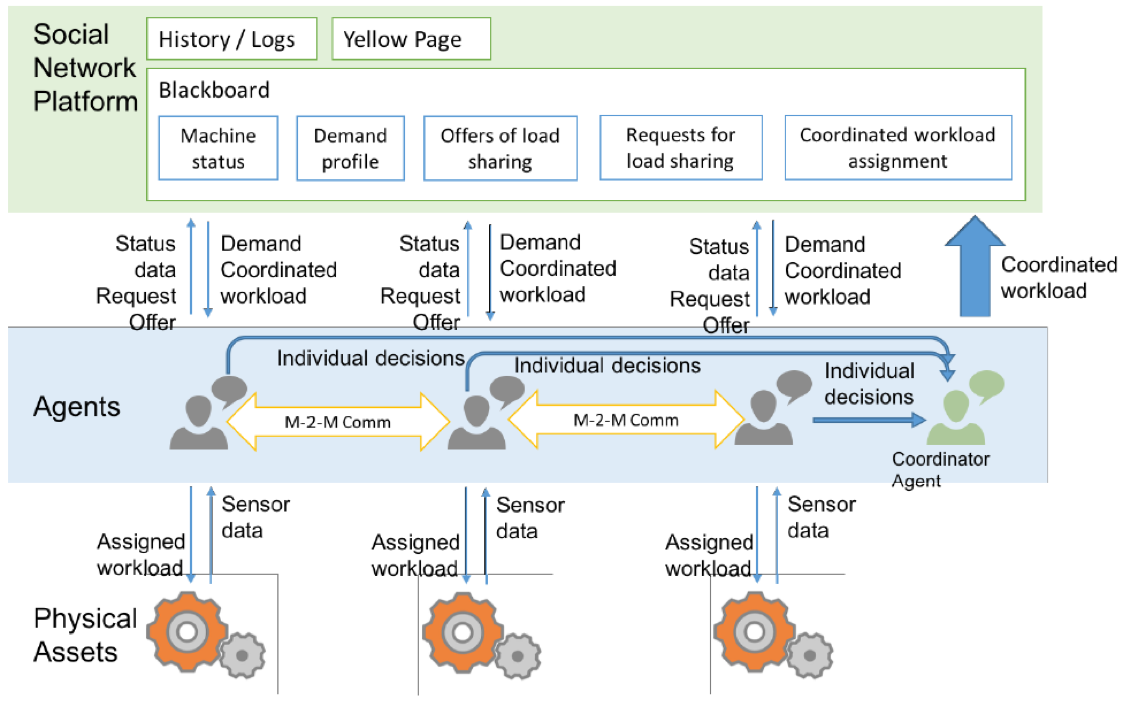

Emerging sensing technologies allow condition monitoring of machines in a production system by equipping them with sensing, communication, data storage and data processing capabilities. Production plants will have “intelligent” machines (represented by digital twins) join a social network specifically designed to enable M2M communications. The machines will provide “status updates” to the social network, thus sharing their condition and operational status with other machines subscribed to the network.

Imagine a world where individual machines in factories around the world collect, upload and share operating performance data via a social network - the possibilities for machine learning and optimisation are significant. Machine status updates will enable plant managers to develop system-wide maintenance plans that optimise reliability, productivity, energy consumption and product quality etc. Intelligent machines (enabled by software agents) will be able to learn from each other, identifying “best practices” for problem solving (e.g., reduce load to improve reliability). The data generated will enable machines to behave in a manner that optimises system-level performance. Machines will be able to advise each other on how they can collectively achieve system performance targets (e.g., one machine instructing another to speed up or slow down in order to maintain production goals while minimising risks). Finally, machines will also be able to optimise their own performance so they “help” other machines (e.g., lower the load for a downstream machine whose condition is deteriorating – as realised through its status updates) such that system cost-risk-performance balance is optimised to generate long-term value. In short, Manufacturing of the Future will be enabled by a society of cooperating machines – very similar indeed to human societies!

Current activities

Our research in this area is progressing in three different directions:

1. Demonstrator development. We are developing a prototype physical demonstrator of a production system where assets are equipped with digital twins and can communicate with each other and work collaboratively through a 'social network platform'.

2. Collaborative prognostics. This research aims to develop algorithms that enable machines to work in a collaborative fashion, learning from each other to improve their failure prediction capabilities.

3. Distributed load management and maintenance. This research aims to develop algorithms that enable a set of similar machines in a system to work together as a team and decide their own production schedules and load considering the optimal value delivery for the system as well as their own health management and associated costs.

People

- Ajith Parlikad

- Maharshi Dhada

- Adria Salvador Palau

- Hao Li

- Mateusz Pniewski

- Mudit Dubey

- Kshitij Bakliwal

Project Partners

- Siemens Industrial Turbomachinery

- Indian Institute of Technology, Indore

- BT

Publications

- Dhada, M.H., Salvador-Palau, A., Parlikad, A.K., “Federated learning for collaborative prognosis,” In Proc. International Conference on Precision, Meso, Micro and Nano Engineering, Indore, December 2019

- Salvador-Palau, A., Dhada, M.H., Bakliwal, K., Parlikad, A.K., An industrial multi-agent system for real-time distributed collaborative prognostics,”

Engineering Applications of Artificial Intelligence, Volume 85, pp 590-606, 2019

- Salvador-Palau, A., Dhada, M.H., Parlikad, A.K., “Multi-Agent System architectures for collaborative prognostics,” Journal of Intelligent Manufacturing, 2019

- Li, H., Palau, A.S., Parlikad, A.K., "A Social Network of Collaborating Industrial Assets," Proceedings of the IMechE Part O: Journal of Risk and Reliability, 2018.

- Salvador-Palau, A., Liang, Z., Lutgehetmann, D., Parlikad, A.K., “Collaborative Prognostics in Social Asset Networks,” Future Generation Computer Systems, Volume 92, pp 987-995, 2019

- Dhada, M.H., Bakliwal, K.K., Salvador-Palau, A., Parlikad, A.K., Lad, B.K., “A multi-agent system architecture to implement collaborative learning for social industrial assets,” In Proc. 16th IFAC Symposium on Information Control Problems in Manufacturing (INCOM), Bergamo, June 2018.

- Li, H., Parlikad, A.K., “Study of dynamic workload assignment strategies on production performance,” In Proc. 20th IFAC World Congress, Toulouse, July 2017.

- Li, H., Parlikad, A.K., “Social Internet of Industrial Things for Industrial and Manufacturing Assets,” 3rd IFAC Workshop on Advanced Maintenance Engineering, Service and Technology, Biarritz, Oct 2016.